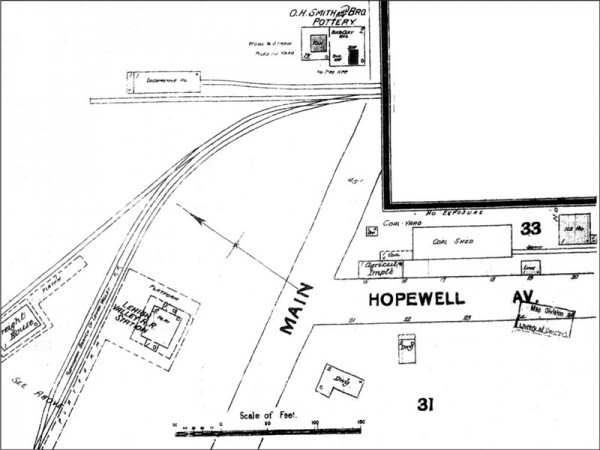

Sanborn Fire Insurance Map depicting the “O. H. Smith and Bro. Pottery,” 1890. The pottery is at the top center of the map.

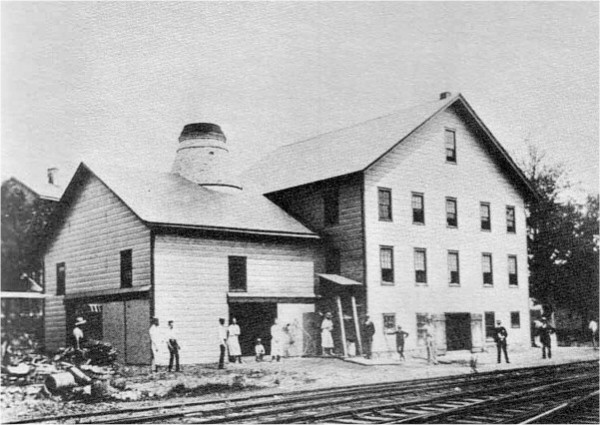

Photograph of the Lehigh Valley Pottery, ca. 1890. (Courtesy, Raritan Township Bicentennial Committee).

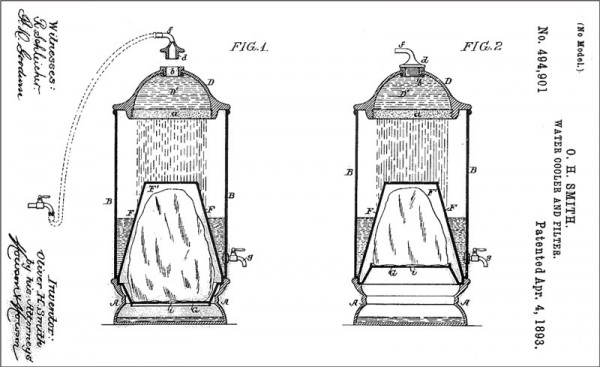

O. H. Smith Water Cooler and Filter, United States Patent Office Drawing No. 494901, April 4, 1893.

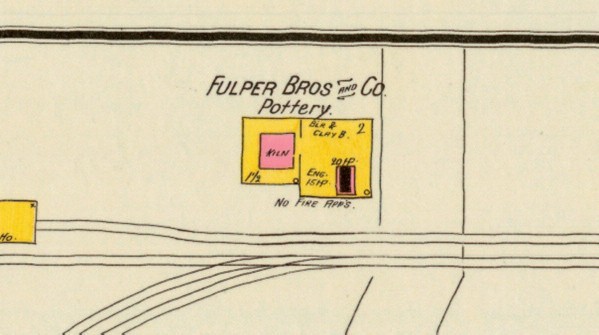

Detail from a Sanborn Fire Insurance Map, illustrating “Fulper Bros and Co. Pottery,” 1896.

Water cooler sherd, Smith/Fulper, ca. 1888–1898. Alkaline-glazed stoneware. Mark: impressed “. . . TER COOLER, / . . . 5, 1886” (All photos, Michael F. Murphy.) The date likely reflects a patent date for the design of Thomas C. Smith’s water cooler, which was granted on May 25, 1886. Although this date predates the opening of the original pottery (1888), the design was most likely in production for several years.

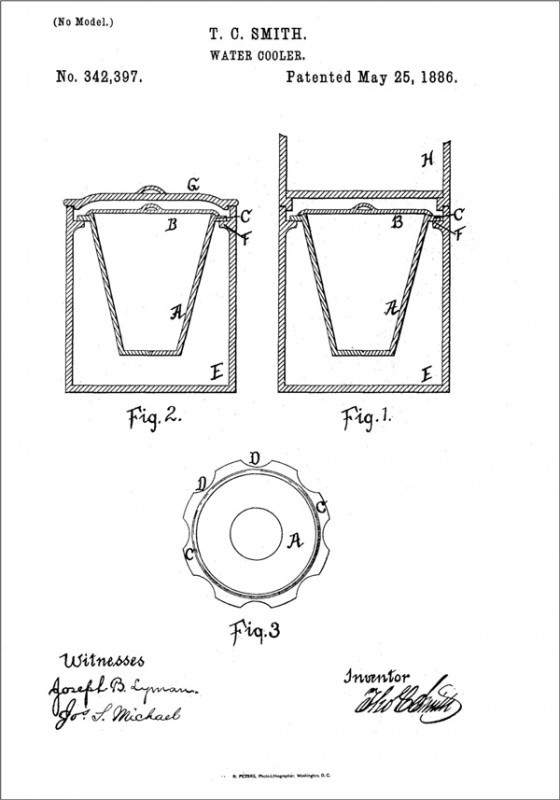

Thomas C. Smith Water Cooler and Filter, United States Patent Office Drawing No. 342397, May 25, 1886.

Water cooler sherds, Smith/Fulper, ca. 1888–1898. Alkaline-glazed stoneware. The top row shows two views of water cooler lid/cap sherds with molded floral decoration and internal threading to hold the filtering stone. The bottom row illustrates two views of a basal dish used for supporting the ice, and a fragment from a circular filtering stone.

Water cooler lid/cap sherd and a filtering stone/slab, Smith/Fulper, ca. 1888–1898. Alkaline-glazed stoneware, with embossed floral decoration. The image shows how the filtering stone/slab fit against the lid.

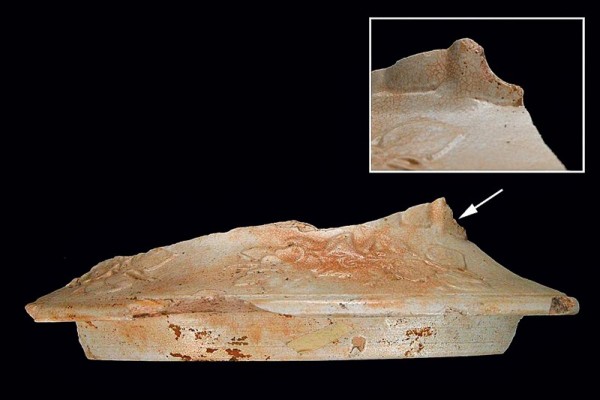

Water cooler lid/cap sherd, Smith/Fulper, ca. 1888–1898. Alkaline-glazed stoneware. A partial water supply hole is indicated by the arrow and is shown in close-up view. A threaded ring was positioned in the hole and secured with a nut. A threaded plug with a nozzle was screwed into the ring, and a flexible tube was attached to the nozzle to fill the cooler with water above the filtering stone/slab. This sherd is different from Smith’s patented design, which shows the water supply hole located farther up the lid/cap positioned directly in the center, suggesting either a design change by Smith or that this might be a Fulper product.

In March 2004 Hunter Research, Inc., carried out a cultural resource survey in the Borough of Flemington, New Jersey. The work was completed in connection with a proposed replacement and realignment of a drainage culvert, in addition to other related roadway improvements. The investigations involved Phase I and II archaeological surveys.

Within the archaeological area of potential effects, the team identified stoneware waster deposits at the intersection of Main Street and Park Avenue. The artifacts were associated with the O. H. Smith and Bros./Fulper Brothers and Company. These deposits and the larger pottery site have been preliminarily evaluated as being eligible for listing on the National Register of Historic Places.

The U.S. Census of 1880 indicates that two Canadian brothers, eighteen-year-old Oliver H. Smith and fifteen-year-old Lincoln Smith, were living in Raritan Township, Hunterdon County, New Jersey, with their parents and three brothers. Their father, Rufus Smith, was identified as a “potterer” and they as “potterer apprentices.” Nine years later, after they had completed their apprenticeships, Oliver and Lincoln Smith founded the Lehigh Valley Pottery.[1] In 1889 they leased a small parcel of land from the Easton and Amboy Railroad Company.[2] They consequently erected a pottery building east of the railroad’s engine house which measured forty feet by seventy feet.[3] In 1890 a Sanborn fire insurance map makes note of the “O. H. Smith and Bro. Pottery” northwest of the locomotive house and freight house that belonged to the Lehigh Valley Railroad (formerly the Easton and Amboy Railroad) just below Main Street (fig. 1). The map reveals that the kiln was housed in a one-and-a-half-story wing appended to the west side of a two-story building. Additionally, the mapmaker observed that the pottery enterprise piled wood and straw in the yard near the kiln. A late-nineteenth-century photograph (fig. 2) depicts the pottery and its convenient proximity to the railroad.

By 1891 business at the Lehigh Valley Pottery was flourishing and the firm subsequently expanded its facility by increasing the building’s width by sixty feet. An additional kiln might have been added, although this modification has not been supported by cartographical evidence.[4] That same year the establishment was described as being “equipped with special machinery and appliances for the manufacture of every variety of stone ware demanded by the trade, in all sizes, and not excelled in style, quality eroelgance [sic] by that of any pottery in the United States.” The company, headed by Oliver H. Smith, Lincoln G. Smith, and their investment partner Charles Alpaugh, introduced an improved design for their pie plate to add to their production of elegant vases, stoneware crocks, jugs, pails, and pots.[5]

In 1891 Oliver H. Smith and his wife sold partial interest in the pottery to Charles Smith, perhaps Smith’s younger brother Charley who was listed in the 1880 census. The deed to the property specifically referenced the “pottery building or factory, the kiln, kiln building, and all other buildings. . . .”[6] The Lehigh Valley Pottery continued operations and began to produce quantities of the “Gate City Stone Water Filter” for its patent holders. Oliver H. Smith endeavored to improve the water cooler’s efficiency by altering the ice chamber and was awarded a patent in 1893 (fig. 3).[7]

The Smiths’ pottery used stoneware clay from Perth Amboy, New Jersey, which was hauled to Flemington by the Lehigh Valley Railroad. William Hill Fulper III, great-grandson of the potter Abraham Fulper, recalled that he “vividly remember[ed] watching two large dappled gray horses hauling a cart loaded with both imported and domestic clay from the Lehigh Valley Railroad station to the pottery, fondly known in Flemington as ‘The Pot Shop.’”[8] The facility employed fifteen men who operated one kiln per week. The enterprise, which stamped its stoneware products “O. H. Smith & Bros. Flemington N.J.,” shipped its goods to dealers in urban centers across the East Coast—Baltimore, Boston, New York, Philadelphia, and Pittsburgh.[9]

By 1894 the Lehigh Valley Pottery was severely afflicted by the economic depression of the previous year and faced competition from other stoneware manufacturers.[10] Oliver H. Smith borrowed money from Charles Smith and from John Creveling, a trustee of the Bloomsbury National Bank. That year the facility was conveyed to John Creveling, trustee for William N. Creveling and the Bloomsbury National Bank.[11] In 1895 the pottery was purchased by the Fulpers, who also obtained the patent for the “Gate City Stone Water Filter” and a line of artware. The filter, composed of two sections, was a popular item that found use in railroad stations, public buildings, and offices.[12]

After the Fulper brothers acquired the pottery, it is possible that they employed the Smith brothers until the Smiths removed to Canada, where they perhaps sought to establish another pottery.[13] In 1897 a city directory indicates that Oliver Smith still resided in Flemington and was employed as an agent.[14] By 1900, however, both Oliver and Lincoln Smith had left New Jersey; Oliver was employed in insurance sales, Lincoln worked as a bookkeeper.[15]

A fire insurance map of 1896 identifies the “Fulper Bros and Co. Pottery” at the location (fig. 4). The enterprise had not been equipped with any fire apparatus. The Fulper Pottery was active only briefly at this location. In 1897–1898 the two mortgages on the main Fulper property located farther south in the town were foreclosed and subsequently the mortgagees purchased those premises. It is likely that this situation compelled the Fulpers to cease production at the former Lehigh Valley Pottery site. The pottery was consequently operated by the Flemington Stoneware Company for a short time until the facility burned in 1900.[16] By 1902 the pottery was no longer extant, as indicated by a fire insurance map published that year.

Excavated stoneware waster sherds from the O. H. Smith and Brothers Lehigh Valley/Smith Pottery (1888–1894) and from the Fulper Brothers and Company Pottery (1895–1898) were collected from three trenches. From this sample it is difficult to distinguish between the two companies. In the main, identified stoneware vessels from the Lehigh Valley/Smith Pottery are salt-glazed, but a few examples exhibit a Bristol slip-glaze coated alkaline glaze, as do marked vessels from the Fulper Brothers and Company Pottery during this period. The similarities of body types and glazes make it difficult to associate individual sherds with a particular pottery. The issue is further complicated by the fact that both companies produced the same vessel forms at the same location. Vessels identified from the trenches consist of jugs, flat lids (for crocks or churns), water coolers, and filtered water coolers. A minor amount of kiln furniture was also recovered from Trench 3, consisting of a variety of pads and rolls used to prop up vessels in the kiln. The majority of vessel sherds exhibit an Albany-type slip glaze on the interior surfaces, with Munsell colors ranging from weak red to dusky red, dark reddish brown, reddish black, dark gray, dark yellowish brown, and dark brown to black.

A stoneware sherd recovered from Trench 2 is impressed “. . . TER COOLER, . . . 5, 1886” (fig. 5). This is presumably a patent date, which predates the existence of the pottery at this location. It most likely represents a water cooler patented on May 25, 1886, designed by Thomas C. Smith of Brooklyn, New York. Thomas Smith had received a patent for a water cooler in August 1873. Thomas Smith was likely a close relative, and the number of years (twenty) between Thomas Smith’s first patent and Oliver H. Smith’s patent suggests he was possibly an uncle. Thomas’s 1886 patent is for a “new and useful Improvement in Water-Coolers.” The invention consists of a water cooler with an interior ice chamber suspended within the water reservoir below a filtering device (fig. 6). The ice chamber A depicted in the patent is identical to the ice chamber depicted in Oliver Smith’s ice chamber labeled F, suggesting that the earlier water cooler was the basis of Oliver’s water cooler seven years later. Why the sherd marked bearing the 1886 date appears at the site of the later Smith facility is unknown, but it seems likely that Oliver and Lincoln manufactured the earlier water cooler until their patent was approved.

A number of sherds were from a specially designed filtered water cooler patented by Oliver Smith on April 4, 1893 (figs. 3, 7, 8). Sherds recovered from Trench 3 that match figures 1 and 2 from the patent application are: a filtering slab or block; D the domed filtering cap, which forms the filtering chamber; and A, on the base of which the dish containing a lump of ice is mounted. The domed lid is decorated with molded flowers (morning glories and wild roses) and vertical ribs. One domed-lid sherd exhibits the remnant of a hole (one-half inch in diameter) presumably used to attach a water supply (fig. 9). The position of the water supply hole differs from Smith’s patent in that it is located on the side instead of the top, as shown in figures 1 and 2 from the patent application. This might reflect changes to the design made by Smith or later by the Fulper Brothers and Company pottery. All of the domed filtering cap’s threading on the vertical flange is covered with a thick coating of unglazed, low-fired gray-bodied clay, which in turn has remnants of the filtering stone adhering to its surface. The low-fired clay appears to have been used as an adhesive to hold the filtering stone in place. The 1893 patent states that the filtering slab can be secured to the lower portion of the cap in any suitable manner. The patent suggests screwing the filtering slab into the lower portion of the cap for ease in cleaning. The excavated specimens, however, show evidence of bypassing the molded threads and using clay to secure the filtering stone.

The Fulper brothers obtained the patent when they purchased the pottery in 1895 and named different versions of the filtered water cooler the “Gate City Stone Water Filter” and the “Fulper Germ-Proof Filter.” Waster sherds from the site suggest the patented cooler system may have undergone undocumented alterations by the Smith or Fulper families. Development of these water coolers later helped vault the Fulper Pottery Company to national and international prominence as a major ceramics company.

ACKNOWLEDGMENTS

The authors wish to acknowledge Michael F. Murphy for the artifacts photography and the New Jersey Department of Transportation for funding the excavations.

William B. Liebeknecht, Principal Investigator, Hunter Research, Inc.;

wbl@hunterresearch.com

Nadine Sergejeff, Historian

Rebecca White, Laboratory Supervisor, formerly of Hunter Research, Inc.

Personal communication with Robert C. Runge Jr., January 12, 2004.

M. L. Branin, Early Makers of Handcrafted Earthenware and Stoneware in Central and Southern New Jersey (Rutherford, N.J.: Fairleigh Dickinson University Press, 1988).

Business Review of the Counties of Hunterdon, Morris and Somerset, New Jersey (Philadelphia: Pennsylvania Publishing Company, 1891).

Ibid.

Ibid.

Hunterdon County Deed, 240/194.

Personal communication with Robert C. Runge Jr., January 12, 2004.

Ibid.

Business Review of . . . Hunterdon, Morris and Somerset.

Branin, Early Makers.

Hunterdon County Deed, 240/196.

Branin, Early Makers.

Personal communication with Robert C. Runge Jr., January 12, 2004.

“Breed Publishing Company’s directory of Lambertville, Flemington, and stations on the line / 1897” (microfiche, New Jersey Historical Society).

United States Census, Population Schedules, 1900.

Ibid.