Teapot, Staffordshire, 1765–1775. Lead-glazed earthenware. H. 4 1/2". (Courtesy, Chipstone Foundation; unless otherwise noted, photos by Gavin Ashworth.)

Map showing locations related to the activities of John Bartlam and William Ellis. (Artwork by Wynne Patterson.)

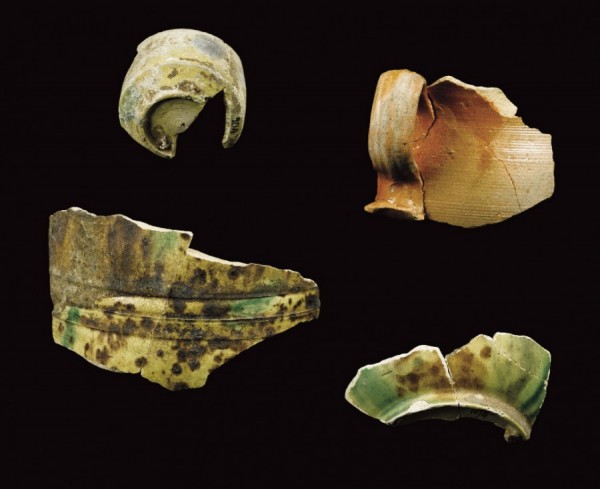

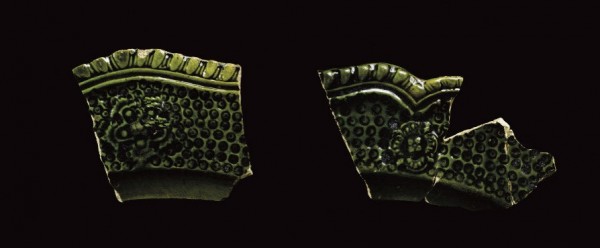

Waster fragments, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

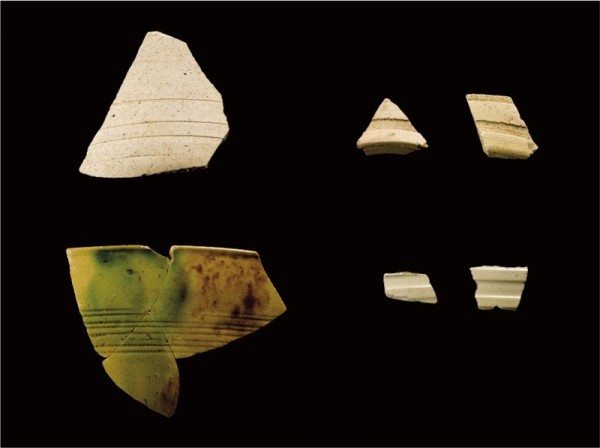

Waster fragments, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Bisque-fired earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

Bowl and mug fragments, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Bisque-fired and lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.) These fragments show clear evidence of lathe-turning. The four mug fragments at far right are virtually identical to a popular decorative technique used on Staffordshire hollow wares in the 1770s.

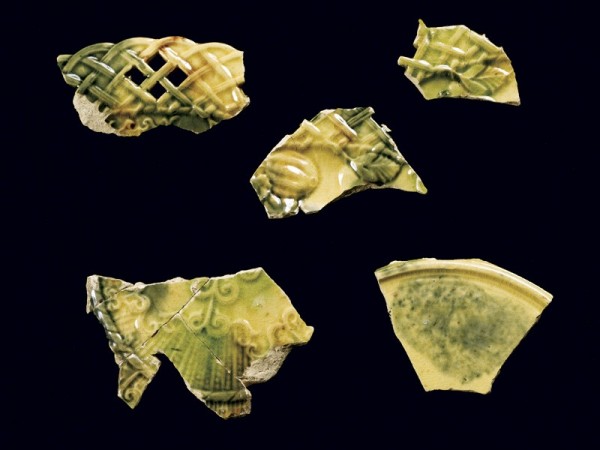

Teapot fragments, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.) Note the incorporation of the molded Barleycorn design on the panels of the vessel.

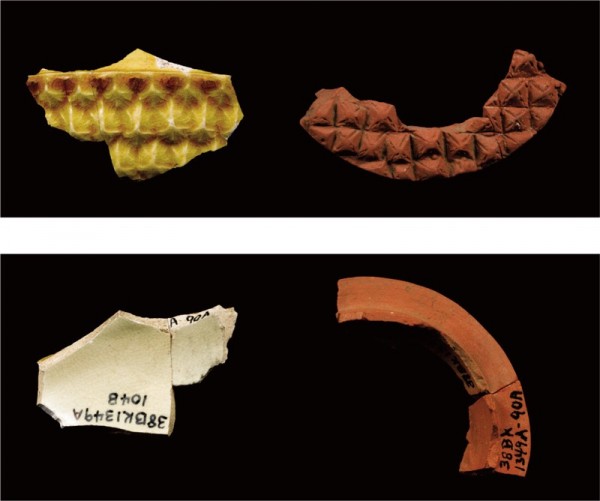

Teapot fragments, attributed to John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware and unglazed red stoneware. (Courtesy,p> South Carolina Institute of Archaeology and Anthropology.) This form in red stoneware has not been seen in English examples.

Bowl fragments, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Bisque-fired and lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

Dish fragments, attributed to John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

Dish, Staffordshire, 1765–1775. Lead-glazed earthenware. H. 8 3/8". (Courtesy, Chipstone Foundation.)

Teabowl fragments, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Soft-paste porcelain. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

Waster fragment, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.) This fragment clearly shows a collapsed vessel, the result of overfiring in the kiln.

Bowl fragments, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.) The tortoise-glazed fragment on the left shows a rouletted rim pattern.

Plate and hollow ware fragments in the Barleycorn design, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Bisque-fired and lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

Plate fragments in the Dot, Diaper, and Basket design, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Bisque-fired and lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

Plate fragments in the Ring and Dot design, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

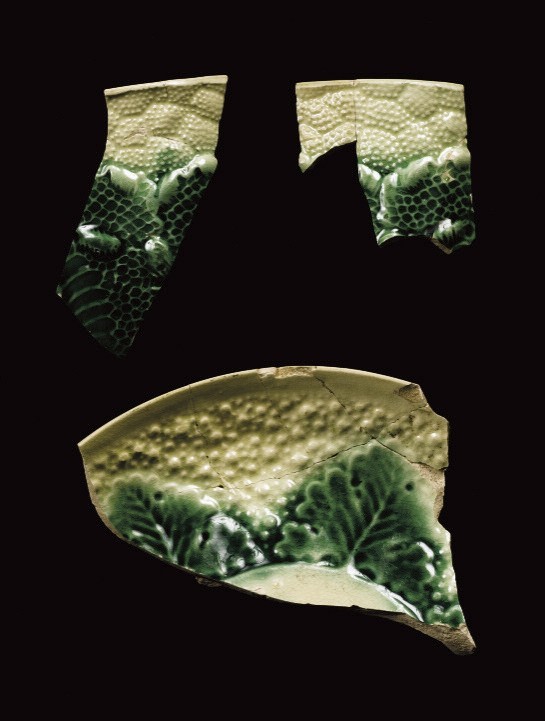

Bowl and saucer fragments in the molded Cauliflower pattern, attributed to John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

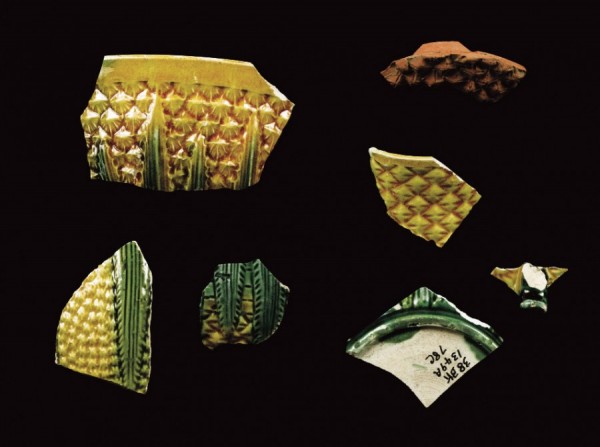

Fragments in the molded Pineapple pattern, attributed to John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware and unglazed red stoneware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

Hollow ware fragments, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Bisque-fired and lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

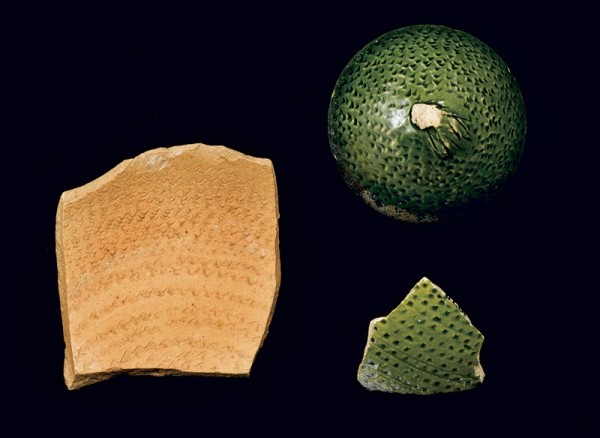

Jug fragment, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

Tortoise-glaze fragments, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

Hollow ware fragment, John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.)

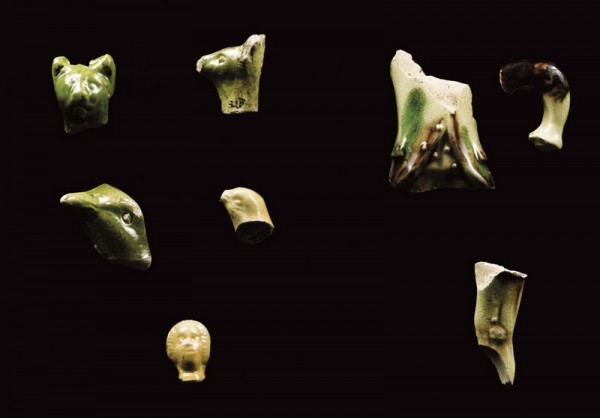

Figural fragments, attributed to John Bartlam, Cain Hoy, South Carolina, 1765–1770. Lead-glazed earthenware. (Courtesy, South Carolina Institute of Archaeology and Anthropology.) These fragments might be from wares Bartlam produced using molds that were widely available in the Staffordshire ceramic industry.

By the 1750s the English ceramics trade was confronted with significant challenges: American consumers were feverishly looking for ways to circumvent the import duties being charged for British goods; the introduction of inexpensive Chinese imports had potters scrambling for ways to reclaim the market; and consumers on both continents were ready for something new. In 1759 Josiah Wedgwood began experimenting with emerald green and golden yellow glazes that would replicate the vibrant colors of nature, and within a year lead-glazed ceramics of green and gold became the rage, as did botanical forms and organic motifs.[1]

As a result of the production of these new forms and colors, the 1760s were remarkably volatile for the ceramics industry. Technological innovation in the Staffordshire ceramics industry and related fields fueled an explosion of new materials, glazes, and artistic expression that in turn presented consumers with an unprecedented variety of lead-glazed earthenwares. The rate at which new techniques and glazes were being introduced was mind-numbing, and potters were stressed to keep up with demand. It was not enough to offer the old standby “delf” and yellow slip-glazed wares; potters were producing white salt-glazed stonewares, mottled earthenwares, brilliant molded wares in yellow and green, and enameled wares. Eventually most manufactories began to specialize in one or two types, which reduced production costs and allowed for more imaginative offerings within each type. As specialization developed, regional tastes and buying trends began to emerge.

When Staffordshire potter John Bartlam agreed to move to Charleston in 1763, he probably envisioned a profitable venture in ceramics manufacturing in the South Carolina Low Country. Charleston was at the center of Southern economic and cultural growth, and probate records and newspaper advertisements indicate that a wide range of ceramic types was popular, including creamware, green-glazed ware, Jackfield ware, porcelains, and stoneware.[2] Even Wedgwood’s bright colors of green and gold were visible on wares made in the shapes of cauliflower, melons, and pineapples (fig. 1). Archaeologically these wares crop up frequently in the Chesapeake Bay and coastal Carolina areas. They do not appear to be as plentiful in the Northern colonies, although shipping documents from the Wedgwood factory indicate trade with Boston and sets of molded teawares have been found archaeologically in sites as far north as Fort Michilimackinac, in present-day Michigan.[3] Many of these wares were sent to the West Indies in the mid-1760s, which could explain their strong presence in the South, as the colonies there maintained strong ties with the West Indies through familial and business relations.[4]

John Bartlam had been working in the potteries in Staffordshire, England, for roughly twelve years before immigrating to Charleston.[5] During that period, 1751–1763, new ceramic types were emerging in Staffordshire—refined earthenwares made with a red- or cream-colored body. Low-fired earthenwares had been perfected by 1740, but by the 1760s a paler, more refined creamware was all the rage in Europe and the colonies, thanks to expert marketing techniques employed by Josiah Wedgwood.[6] Encouraged by reports of good clay and a ready client base, Bartlam moved to Charleston about 1763 with the purpose of establishing a potworks.[7] In September 1765 an advertisement in the South Carolina Gazette announced the establishment of his manufactory near Charleston:

We are informed, that a gentleman, lately from England, who has lately set up a pottery about 9 miles from this, has met with so good Clay for his purpose, that he scarce doubts of his ware’s exceeding that of Delft: He proposes to make every kind of earthenware that is usually imported from England, and as it will be sold cheaper, he cannot fail to meet with encouragement.[8]

Bartlam’s pottery manufactory was located in St. Thomas Parish in a settlement known in the eighteenth century as Cain Hoy, on the north bank of the Wando River, nine miles north of Charleston (fig. 2). The Cain Hoy district, which had a reputation for good clay sources, had a well-established brick-making industry—at least five brickyards were in existence by the 1760s.[9] The availability of local resources, the location on a navigable river, and a ready supply of bricks needed for the pottery ovens made Cain Hoy and its surroundings an excellent choice for the potworks.

In their search for John Bartlam’s first production site, archaeologist Stanley South, with his team from the South Carolina Institute for Archaeology, and Brad Rauschenberg, then director of research at the Museum of Early Southern Decorative Arts, focused on Cain Hoy.[10] Their archaeological investigations recovered unique and notable creamware examples whose quality and variety were on a par with those made in contemporary Staffordshire factories. Although remnants of the kiln and related processing features have yet to be discovered, the initial findings led South to consider Bartlam as America’s first creamware potter.[11]

Advertisements in the South Carolina Gazette reveal that John Bartlam began marketing his wares two years after his initial voyage to Carolina.[12] According to a letter from Josiah Wedgwood to Sir William Meredith of Liverpool, Bartlam was also soliciting help from workers in England who wished to relocate to Carolina.[13] By 1769 he was able to mortgage five hundred dozen pieces of earthenware and was advertising for more help at his Cain Hoy pottery manufactory.[14] The archival evidence points to a potter whose presence was known in the Charleston marketplace and who was enjoying at least moderate success.

Cain Hoy Pottery

Early archaeological investigations of the Cain Hoy pottery site produced thousands of pottery sherds, many of which could not have been produced during John Bartlam’s tenure. The task for Stanley South and his team was to extricate locally made sherds from the mass of artifacts and to define the individual style of potters who had worked at Cain Hoy. In his initial analysis of Cain Hoy ceramics, South identified nearly forty ceramic types that could be attributed to potter John Bartlam.[15] Subsequent research helped to refine the criteria needed to support an attribution to John Bartlam.[16]

At the time Bartlam was producing in Cain Hoy, from sometime after 1763 until about 1770, the most popular British wares—which would, of course, have been most profitable for a new potter—essentially fell within three groups: refined earthenwares, including creamware, Jackfield ware, and the green-and-gold–glazed wares; white salt-glazed stonewares; and porcelain.

The recovered archaeological evidence illustrates the range and diversity of Bartlam’s earthenware repertoire, indicating that he had mastery over most of the prevailing ceramic fashions of the period. The sophistication displayed in his products suggests that Bartlam must have brought with him from England an array of hand tools, molds, wheels, and lathes. Having both the knowledge and the necessary equipment gave him the capability of manufacturing wares that were virtually indistinguishable from Staffordshire imports.

Using local clays, Bartlam produced a variety of thrown and molded table- and teawares, including tortoise-colored creamware, pineapple, cauliflower, and green-glazed wares (figs. 3, 4). Bisque-fired and glazed sherds found at Cain Hoy included plain or lathe-turned bowls, cups, saucers, and mugs (fig. 5). A large quantity of bisque-fired sherds found at the Cain Hoy site confirms the manufacture of press-molded plates there. Many of the patterns are commonly associated with English white salt-glaze, including the Dot, Diaper, and Basket and Barleycorn designs. An example of the latter is incorporated into the panels of a large molded teapot decorated with manganese and copper oxides in the tortoise style (fig. 6). The colors of the wares range from a pale beige to a dark pink.

Bartlam also made other molded teaware, including unique examples of pineapple teapots in unglazed red stoneware (fig. 7). Glazed as well as bisque-fired fragments of cauliflower-pattern bowls and small plates were recovered (fig. 8). Among the most sophisticated and decorative dishes possibly made by Bartlam are press-molded baskets and dishes covered in a rich green glaze, a type popular with many Staffordshire manufacturers (figs. 9, 10). Also found among the thousands of earthenware ceramic fragments, and seemingly of local manufacture, were fragments of blue-decorated porcelain teabowls, saucers, and punch bowls (fig. 11).[17]

The Cain Hoy excavations also presented a number of kiln waster sherds that are presumed to be solely from potting activities at Cain Hoy. Kiln wasters result when the manufacturing process has gone awry, and they appear in many forms: bisque-fired pieces that collapsed or fused in the kiln; glazed pieces that were underfired, underglazed, or damaged in some way; dirt or clay intrusions; overfiring or bubbling of the glaze (fig. 12). These kiln wasters form the basis of the analysis used to determine Bartlam’s ceramics production techniques.

The Cain Hoy Technique

Failure to locate a kiln at the Cain Hoy site, coupled with the presence of imported ceramics types among locally produced wares, made it difficult to utilize the standard typologies for ceramics; that is, stricter criteria had to be used to assign a ware type “locally made” status. After thorough analysis of the archaeologically recovered materials, including waster sherds, bisque wares, and those pieces unique to Cain Hoy, a style of pottery began to emerge that clearly was different from imported wares. The wares appear to have been hand-turned by a talented potter rather than slip cast; the curves are distinctive; even the manner of applying some of the decorations differs from typical Staffordshire products—all making it possible to distinguish John Bartlam’s wares from the imports.

Cain Hoy earthenwares that are deemed “locally made” have a specific set of characteristics (fig. 13). They are hand-turned, with red or cream-colored clay bodies. The glazes are consistent—yellow or orange lead with underglazes of brown or green. It is probable that Bartlam was experimenting with clay types when he arrived in the Carolinas, which would explain the wide range of colors seen in the bisque and glazed fragments.

Bartlam mentions bringing molds and tools with him to Charleston but we have no record of what they were. However, several of the bisque wares and kiln wasters have surface designs, which were standard patterns in the Staffordshire potting industry and familiar to American consumers of refined earthenwares and white salt-glazed stonewares. The patterns listed below have been identified on bisque sherds or kiln wasters found at Cain Hoy.

Barleycorn molded design. Bartlam may have brought plate molds in this popular pattern from Staffordshire (fig. 14). There is evidence to suggest that he then adapted the molds to create hollow ware. The most intriguing object among the Barleycorn fragments is a tortoiseshell-glaze teapot with a continuous barley pattern on the surface (see fig. 6). The Barleycorn design can also be seen on green-glazed wares from the site.

Dot, Diaper, and Basket design. This molded pattern is a standard in Staffordshire plates, dishes, and hollow wares. It consists of alternating sections of dots within crossed lines, basket weave, and either intricate plaid or parallel lines. Fragments of bisque-fired and green-glazed plates were found in the excavation (fig. 15).

Ring and Dot impressed. Found mostly on green-glazed wares, this design appears on Staffordshire flatwares and hollow wares. The somewhat irregular pattern seen on the Cain Hoy examples may suggest that the molds were produced locally (fig. 16).

Cauliflower and Pineapple wares. Many molded botanical designs were developed in this period, yet those by Bartlam tend to be slightly different. The Cauliflower bisque wares are smaller than the imports, as are the Pineapple wares (fig. 17). The pineapples have a small amount of incising on the surface, and elements of the design are cut into the clay rather than rising as a low relief on the surface.[18] The glazed Cauliflower and Pineapple kiln wasters have a yellower tint than is typical for Staffordshire examples, suggesting high levels of iron impurities in Bartlam’s glaze (fig. 18).

Melon ware. Thrown Melon wares were one of the simpler and more popular types of the period. The impressed rouletted designs on the surface of these green-and-yellow–glazed wares are intended to simulate watermelon, cantaloupe, or honeydew (fig. 19). The glaze tends to be lighter green with yellow, and the rouletting is playful and haphazard across the piece (fig. 20). Both kiln wasters and bisque-fired wares exist on this site.

The wares that appear to be locally made at the Cain Hoy site are decorated with a specific set of colors and types of lead glaze. The predominant glaze is a golden yellow lead one, similar to that found on the earliest Staffordshire creamwares.[19] The bisque-fired tortoiseshell vessels were dusted with powdered oxides of manganese and copper before the glaze was applied (fig. 21). None of the tortoiseshell waster sherds from the site has any of the cobalt shades seen in some imported wares.

A bright green copper-and-lead glaze, which parallels the green glaze perfected by Wedgwood in 1759, was also prevalent among the Cain Hoy artifacts (fig. 22).[20] Possibly because of changes in the firing temperature and uneven oxygen levels in the wood-fired kilns, the green occasionally became slightly olive in color, but the consistency and tone of the glaze were recognizable. Iron and manganese were used to color a group of wares from pumpkin to almost black.

Despite the numerous combinations of colors and designs, the basic techniques used by Bartlam are visible in the various forms and clays. While the full range of his work might not yet have come to light (fig. 23), the wares found here are clearly different from the imported wares found on the site. They reflect the work of a craftsman whose skill at turning was rivaled only in his native Staffordshire. The glazes are as desirable as any import on the Charleston market, and the forms are versatile and functional yet beautiful. John Bartlam, the Cain Hoy potter, was capable of making fine ceramics, a remarkable manifestation of Staffordshire technical know-how on American soil.

Wolf Mankowitz, Wedgwood (New York: Dutton, 1953), pp. 29–31.

Records of Estates, Public Records Office, London; South Carolina Gazette and Country Journal, August 20, 1763.

J. Jefferson Miller, Eighteenth-Century Ceramics from Fort Michilimackinac: A Study in Historical Archeology, Smithsonian Studies in History and Technology 4 (Washington, D.C.: Smithsonian Institution Press, 1970).

John Thomas, The Rise of the Staffordshire Potteries (New York: Augustus Kelley, 1971), p. 106.

Bradford L. Rauschenberg, “John Bartlam, Who Established ‘new Pottworks in South Carolina’ and Became the First Successful Creamware Potter in America,” Journal of Early Southern Decorative Arts 17, no. 2 (November 1991): 2–11; South Carolina Gazette and Country Journal, May 16, 1769.

Donald C. Towner, English Cream-Coloured Earthenware (London: Faber and Faber, 1957), p. 3.

Rauschenberg, “John Bartlam,” p. 3.

South Carolina Gazette, September 28, 1765.

Lucy B. Wayne, “Burning Brick: A Study of Lowcountry Industry,” Ph.D. diss., University of Florida, Gainesville, 1992.

Stanley South, John Bartlam: Staffordshire in Carolina, South Carolina Institute of Archaeology and Anthropology Research Manuscript Series 231 (Columbia: University of South Carolina, 2004); Rauschenberg, “John Bartlam,” pp. 1–66.

Stanley South, The Search for John Bartlam at Cain Hoy: American’s First Creamware Potter, South Carolina Institute of Archaeology and Anthropology Research Manuscript Series 219 (Columbia: University of South Carolina, 1993).

South Carolina Gazette, September 28, 1765.

Rauschenberg, “John Bartlam,” p. 3.

South Carolina Mortgages, Columbia, April 26, 1768, no. A.A.A., 1766–1769, pt. 2, p. 343; South Carolina Gazette and Country Journal, June 6, 1769.

South, Search for John Bartlam at Cain Hoy, pp. 17–36.

See Lisa R. Hudgins, “Ceramic Artifacts at Cain Hoy: Taking a Second Look,” Appendix 11 in South, Search for John Bartlam at Cain Hoy, pp. 209–23.

Robert Hunter, “John Bartlam: America’s First Porcelain Manufacturer,” in Ceramics in America, edited by Hunter (Easthampton, Mass.: Antique Collectors’ Club for the Chipstone Foundation, 2007), pp. 193–96.

Michelle Erickson, personal communication with author, 2008.

Towner, English Cream-Coloured Earthenware.

Mankowitz, Wedgwood, p. 29.