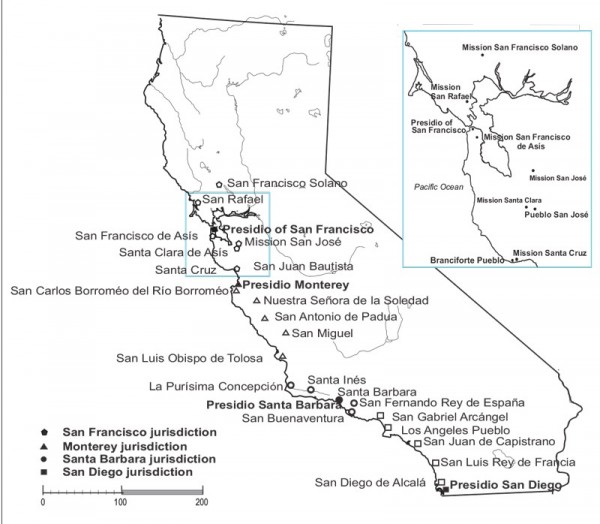

Map of Alta California showing presidio districts and associated missions, pueblos, and presidios during the Spanish and Mexican era, 1769–1848. (Ronald L. Bishop, Smithsonian Institution.)

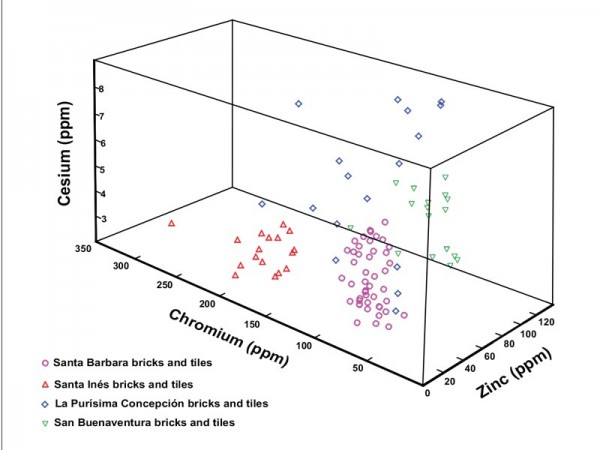

Plot of the data obtained for the architectural ceramics from Santa Barbara Presidio and Missions Santa Barbara, Santa Inés, La Purísima Concepción, and San Buenaventura. The sample locations are shown relative to their abundance of cesium, chromium, and zinc. (M. James Blackman, Smithsonian Institution.)

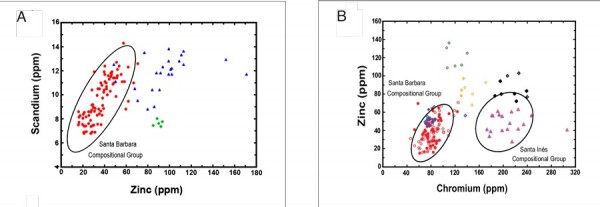

(A) Plot of the bricks, tiles, and plain ceramic ware from the Santa Barbara Presidio, Missions Santa Barbara and San Buenaventura, and the Olivas Adobe relative to the abundances of scandium and zinc. The two statistically refined groups enclosed with 95% confidence ellipses are composed of the samples from Santa Barbara and San Buenaventura chemical group 1. The green down-pointing triangles represent Mission San Buenaventura bricks and tiles of chemical group 2. (B) Plot of the bricks, tiles, and plain ceramic ware from the Santa Barbara Presidio, Missions Santa Barbara and San Buenaventura, and Olivas Adobe relative to the abundances of chromium and zinc showing all of the San Buenaventura ceramics from the Santa Barbara chemical group. (M. James Blackman, Smithsonian Institution.)

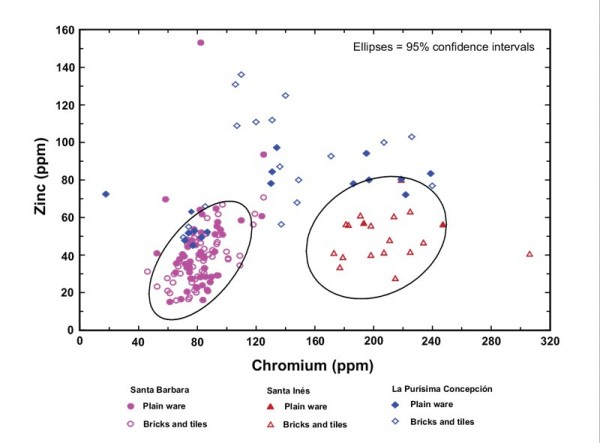

Plot of bricks, tiles, and plain earthenware ceramics relative to the abundance of chromium and zinc. The two statistically refined groups are enclosed with 95% confidence ellipses. Resolution of the overlap between ceramics from Mission Santa Barbara and La Purísima Concepción is illustrated in fig. 5. (M. James Blackman, Smithsonian Institution.)

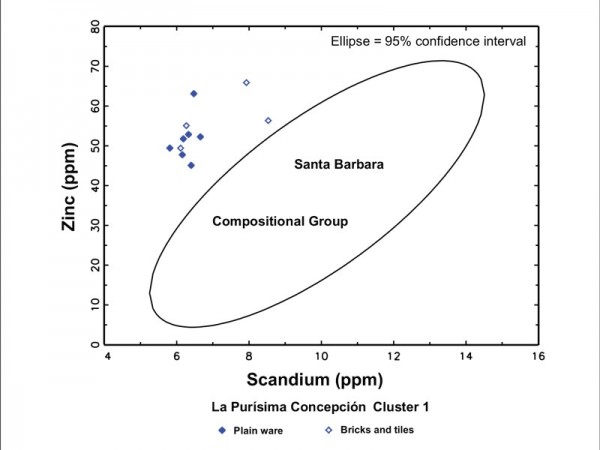

Plot of La Purísima Concepción cluster 1 plain earthenware and architectural ceramics shown relative to concentrations of scandium and zinc. All of the La Purísima Concepción ceramics are shown to lie outside of the 95% confidence interval for the Santa Barbara compositional group. (M. James Blackman, Smithsonian Institution.)

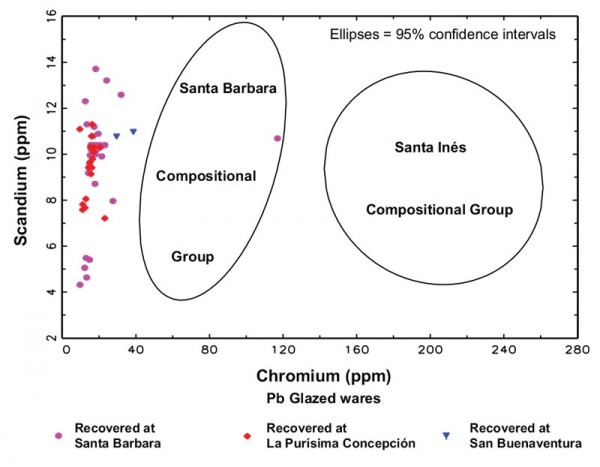

Plot of the concentrations of chromium vs. scandium for all the lead-glazed earthenwares recovered from sites in the Santa Barbara jurisdiction relative to the 95% confidence ellipses for the Santa Barbara and Santa Inés architectural and plain earthenware ceramics compositional groups. (M. James Blackman, Smithsonian Institution.)

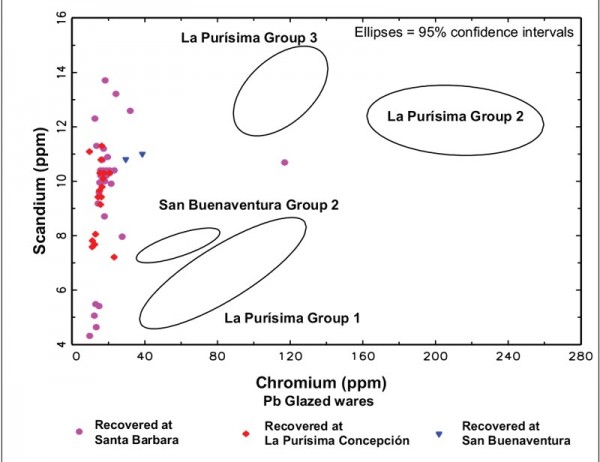

Plot of the concentrations of chromium vs. scandium for all the lead-glazed earthenwares recovered from sites in the Santa Barbara jurisdiction relative to the 95% confidence ellipses for the San Buenaventura and La Purísima Concepción architectural and plain earthenware ceramics compositional groups. (M. James Blackman, Smithsonian Institution.)

Fragments of bricks and tiles recovered from archaeological excavations at El Presidio de Santa Barbara (CA-SBA-133), Santa Barbara, California, 2005. (Photo, Michael Imwalle.)

Civilian Conservation Corps members making roof tiles at La Purísima Concepción, near Lompoc, California, ca. 1938. (Courtesy, La Purísima Mission State Historic Park Archives.)

The arc of a curved roof tile replicated by students at El Presidio de Santa Barbara State Historic Park, 2007. (Photo, Michael Imwalle.)

Unfired roof tiles drying on curved plaster molds cast from original Presidio roof tiles, 2007. (Photo, Michael Imwalle.)

(Left) Roof tile made with somewhat dry clay; (right) roof tile formed with somewhat wet soft clay, which is relatively flat or collapsed, 2007. (Photo, Michael Imwalle.)

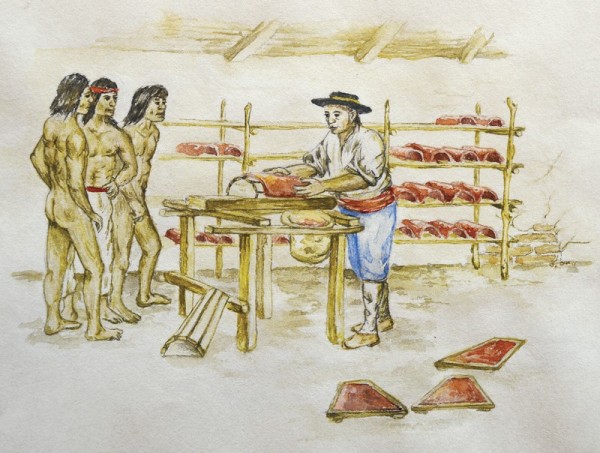

The Chumash Indians learned tile making at La Purísima Concepción and other missions in the region. Oil painting, artist and date unknown. (Courtesy, Santa Barbara Presidio Research Center.)

Clamp-style brick kiln at Colonial Williamsburg, Virginia. (Photo, Michael Imwalle.) Note the multiple stoking holes.

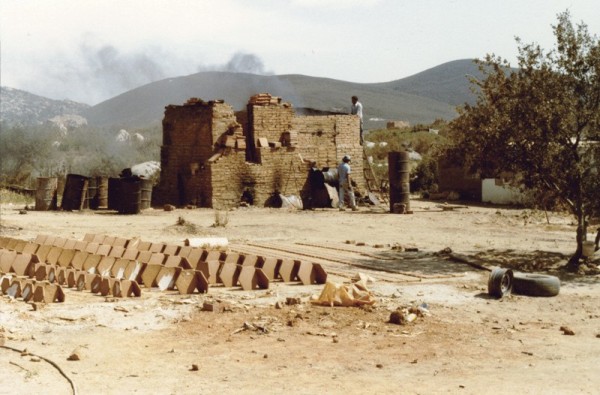

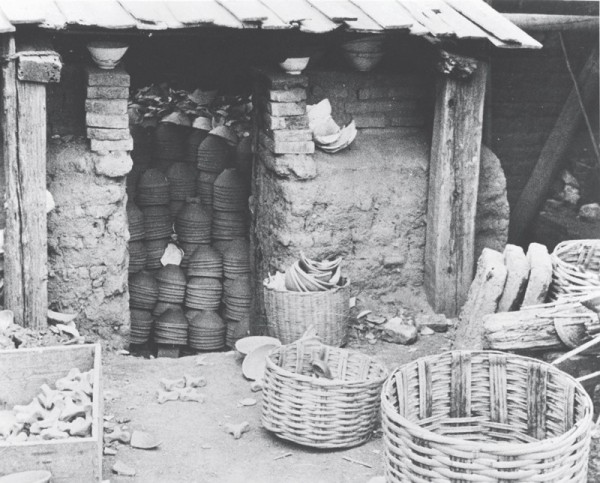

Brick and tile kiln, Mexico, ca. 1950s. (Courtesy, Santa Barbara Mission Archive Library, Edith Webb Collection; photo, Arthur Woodward.)

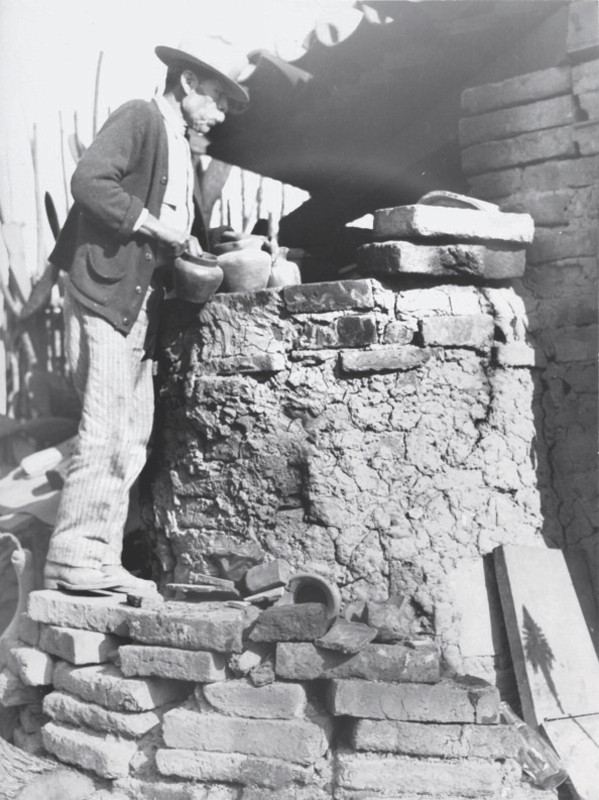

Located in Tecate, Mexico, this brick-and-tile kiln owned by George Davidson fired the roof and floor tiles for the 1985 reconstruction of the Santa Barbara Presidio Chapel. (Photo, Michael Pownall.)

Two-chamber updraft brick kiln used by Franciscan friars during the 1942 restoration of Mission San Miguel in California. (Courtesy, Santa Barbara Mission Archive Library, Edith Webb Collection.)

Bricks and tiles produced by the Redwind Native American Community in San Luis Obispo, California, 1980. (Courtesy, Santa Barbara Presidio Research Center; photo, Norman Caldwell.)

Updraft brick-and-tile kiln used by the Redwind Native American Community, 1980. (Courtesy, Santa Barbara Presidio Research Center; photo, Norman Caldwell.)

“Volcano-style” kiln at Mission San Juan Capistrano. (Drawing by Jack S. Williams; illustrated in “Field Notes: Kiln Documentation, Mission San Juan Capistrano [CA-ORA-856H],” 1996.)

(Left) Small, open-top circular tile kiln at Mission San Luis Rey de Francia; (right) large, open-top circular tile kiln at Mission San Luis Rey de Francia, 2009. (Photos, Michael Imwalle.)

Sketch by José Cardero of the Monterey Presidio, with inset showing tile kiln details, 1791. (Courtesy, Bancroft Library.)

Circular, open-top tile kilns used during the 1920s restoration of the San Bernadino Asistencía of Mission San Gabriel. (Courtesy, Santa Barbara Mission Archive Library, Edith Webb Collection.)

Archaeologist M. R. Harrington alongside La Purísima Concepción tile kiln, 1940. (Courtesy, La Purísima Mission State Historic Park Archives.)

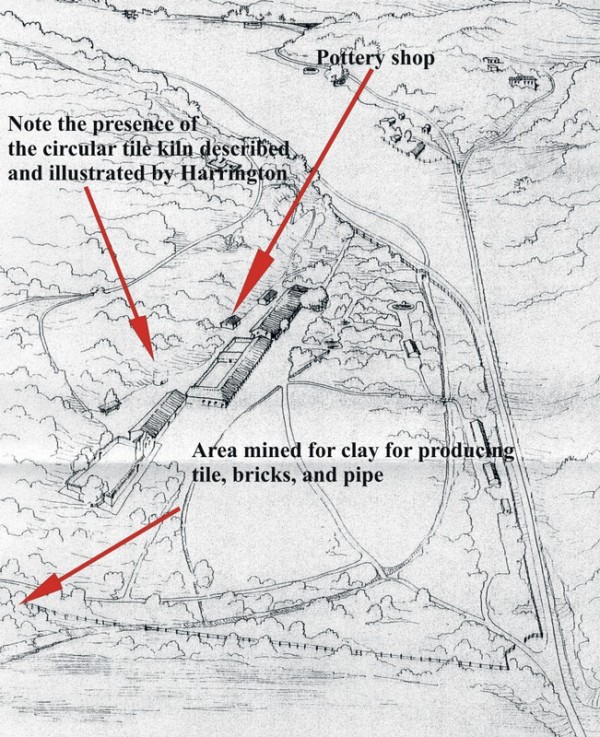

Map of La Purísima Concepción complex with ruins of circular tile kiln, 1938. (Courtesy, La Purísima Mission State Historic Park Archives.)

Reconstructed arch of feature interpreted as a tile kiln by M. R. Harrington at La Purísima Mission State Historic Park, 2007. (Photo, Michael Imwalle.)

Large tallow vat added to top of feature formerly interpreted as a tile kiln by M. R. Harrington, 2007. (Photo, Michael Imwalle.)

Scale model (1/10th) of Mission San Antonio tile kiln based on Julia Costello’s 1997 plan. (Photo, Ruben Reyes.)

Scale model (1/10th) of Mission San Antonio tile kiln with one of the added slanted or “cockeyed” entryways removed. (Photo, Ruben Reyes.)

Close-up of Mission San Antonio kiln model showing position of fired tile arches that would form the firing chamber of a two-chamber updraft kiln. (Photo, Ruben Reyes.)

Top of arches forming the open floor or grate of the ware chamber, La Purísima Mission State Historic Park, 2007. (Photo, Michael Imwalle.)

Interior arches of a two-chamber updraft kiln, La Purísima Mission State Historic Park, 2007. (Photo, Michael Imwalle.)

Firing of 1/10th-scale model of the tile kiln at Mission San Antonio, 2007. (Photo, Ruben Reyes.) This demonstration helped to better understand how the structure was modified from its original use.

Kelly Greenwalt learned the fundamentals of making pottery in about forty hours under the watchful eye of master potter Ruben Reyes, 2006. (Photo, Russell K. Skowronek.)

A bucket of unprocessed clay from Mission Creek near Mission San José close to the eastern shores of San Francisco Bay, 2006. (Photo, Ruben Reyes.)

Reconstructed pottery shop at Mission La Purísima Concepción, 2007. (Photo, Michael Imwalle.) Large amounts of clay would have been pulverized in this mixing vat. Historically a burro would have provided the power for reducing the clay to a satisfactory consistency.

Mixed clay from Mission San José ready for aging and drying, 2006. (Photo, Ruben Reyes.)

Block of clay from Mission San José ready for wedging, 2006. (Photo, Ruben Reyes.)

Wedging, a very labor- and time-intensive endeavor, is necessary for removing air bubbles prior to pottery making, 2006. (Photo, Kelly Greenwalt.)

A ball of processed clay from Mission San José ready to be used, 2006. (Photo, Ruben Reyes.)

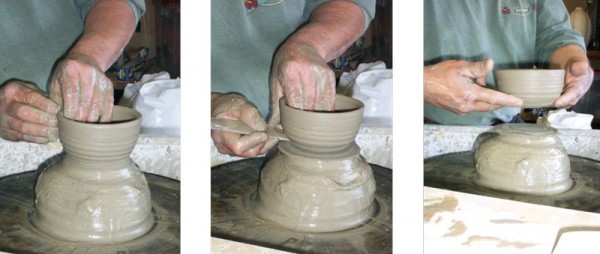

Throwing from the mound was one of the techniques used in Spanish California. (Left) a small bowl or cup is being “pulled” from the mound; (center) the nearly finished cup is cut from the mound; (right) the finished vessel is lifted from the mound, leaving the remainder of the clay for the next vessel, 2006. (Photos, Kelly Greenwalt.)

Base of a ceramic vessel found at Mission San Antonio de Padua, near Jolon, California, bearing the distinctive marks associated with vessels thrown from the mound, 2006. (Photo, Ruben Reyes.)

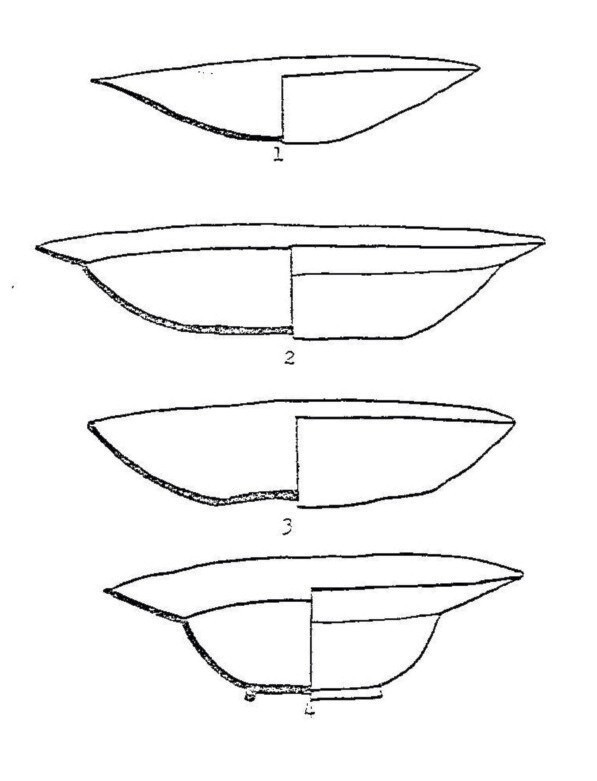

Jack Williams was able to reconstruct several forms of plates and brimmed bowls in his analysis of ceramics from Mission San Antonio de Padua. (Drawing by Elizabeth Skowronek, based on original in Williams, “Early Nineteenth Century Plainware Pottery from Mission San Antonio de Padua Alta California” [1983], ms. on file at Mission San Antonio Archives, Jolon, California.)

Replicated 10 1/2" wheel-thrown brimmed bowl based on forms from Mission San Antonio de Padua, 2015. (Photo, Ruben Reyes.)

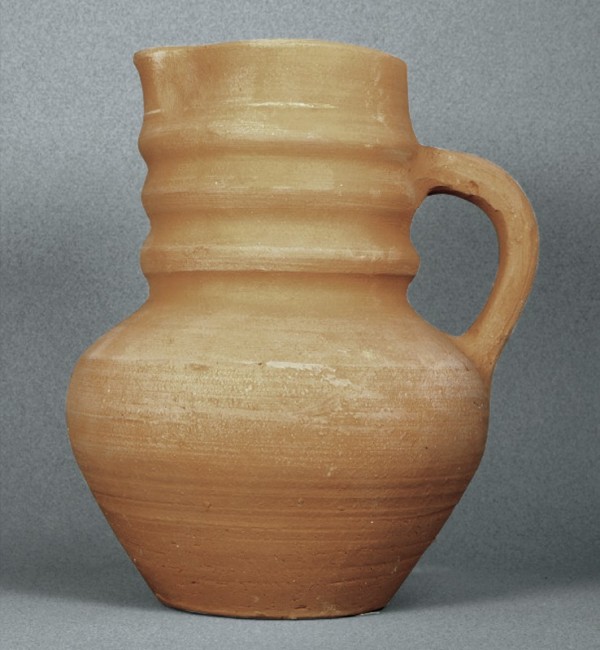

This nearly intact 4" diameter wheel-thrown small bowl or cup was excavated at Mission San Antonio de Padua, 2006. (Photo, Ruben Reyes.)

Replicated 4" diameter wheel-thrown small bowl or cup based on the original found at Mission San Antonio de Padua, 2006. (Photo, Ruben Reyes.)

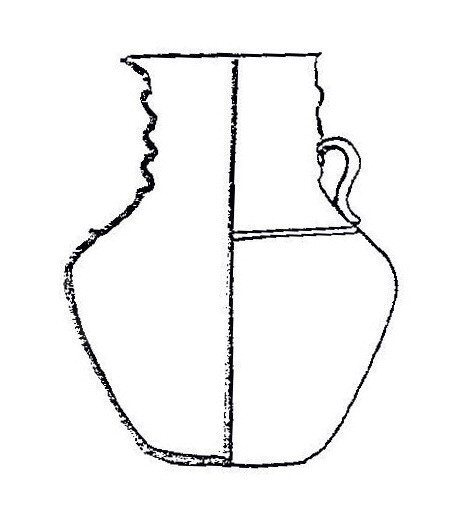

Jack Williams was able to reconstruct a chocolotera (chocolate pot) based on sherds found at Mission San Antonio de Padua. (Drawing by Elizabeth Skowronek, based on original in Williams, “Early Nineteenth Century Plainware Pottery from Mission San Antonio de Padua.”)

Replicated 9" wheel-thrown chocolotera with pulled handle, based on Jack Williams’s 1983 reconstruction at Mission San Antonio de Padua, 2015. (Photo, Michael Imwalle.)

Found at Mission San Antonio de Padua, this 10" wheel-thrown storage or cooking vessel may have been modeled after basketry forms. (Photo, Michael Imwalle.)

Replicated wheel-thrown storage or cooking vessel based on one found at Mission San Antonio de Padua, 2015. (Photo, Michael Imwalle.)

This shallow, 7" diameter bowl or plate was found at Mission Santa Clara de Asís. (Photo, Ruben Reyes.) It was made using the anvil technique.

Ceramic anvils made by Ruben Reyes, 2006. (Photo, Ruben Reyes.)

A slab of clay is placed on the anvil, then paddled over the anvil, 2006. (Photo, Kelly Greenwalt.)

The anvil is carefully removed from the now-formed clay bowl, 2006. (Photo, Kelly Greenwalt.)

The clay bowl awaiting a final trimming of excess clay, 2006. (Photo, Kelly Greenwalt.)

College students from Santa Clara University in 2007 were making vessels in less than thirty minutes using the anvil technique. (Photo, Ruben Reyes.)

Experiments with open-pit fires demonstrated the utility of this production process, 2007. (Photo, Ruben Reyes.)

Close-up of “firing clouds” produced on vessels during experimental pit firing, 2007. (Photo, Ruben Reyes.)

Ruben Reyes adjusting flue to regulate heat of demonstration kiln during experimental firing at El Presidio de Santa Barbara State Historic Park, 2006. (Photo, Michael Imwalle.)

Saggers produced by Ruben Reyes for experimental glaze firing, 2006. (Photo, Michael Imwalle.)

Example of both clavos and clay rods supporting mayólica vessels in a cutaway view of a sagger, 2006. (Photo, Michael Imwalle.)

Replica San Elizario Polychrome mayólica vessel supported by fired clay rods used to support maiolica vessels. (Photo, Michael Imwalle.)

Example of Spanish colonial caballitos found at Mission Nuestra Señora del Espíritu Santo de Zúñiga in Goliad, Texas, 2008. (Photo, Russell Skowronek.)

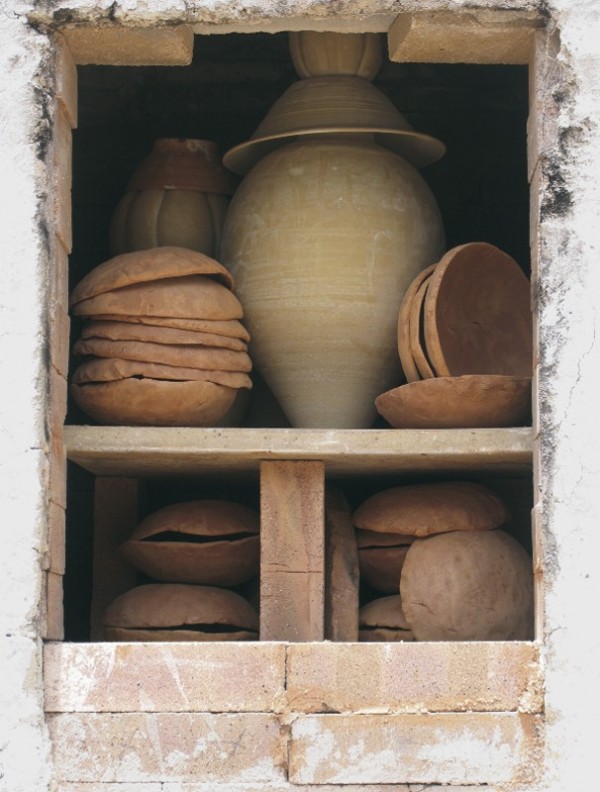

Mexican kiln loaded with vessels for a bisque firing, ca. 1950s. (Courtesy, Santa Barbara Mission Archive Library, Edith Webb Collection; photo, Arthur Woodward.) Note caballitos in left foreground.

Replicated San Agustín Blue-on-white mayólica replica with caballito in place after firing, 2007. (Photo, Michael Imwalle.)

Visible in this close-up are the scars left in the surface of the glaze of this replicated San Elizario Polychrome mayólica vessel, a result of breaking the caballito free of the vessel, 2007. (Photo, Michael Imwalle.)

Santa Barbara Mission with pottery kiln in foreground, 1880s. (Courtesy, Santa Barbara Mission Archive Library, Edith Webb Collection.)

Detail of the photograph illustrated in fig. 67.

Potter Ireneo Mendoza with top-loading, updraft pottery kiln at Mission San Juan Capistrano, 1937. (Courtesy, Santa Barbara Mission Archive Library, Edith Webb Collection; photo, Hugh Pascal Webb.)

Overview of pottery production and firing demonstration at El Presidio de Santa Barbara State Historic Park, Santa Barbara, California, 2006. (Photo, Michael Imwalle.)

Pottery shop and potter’s wheel at La Purísima Mission State Historic Park, 2006. (Photo, Ruben Reyes.)

Replica pottery kiln at La Purísima Mission State Historic Park, 2006. (Photo, Michael Imwalle.)

Ruben Reyes constructing arches, frame, and walls of a two-chamber updraft demonstration kiln at El Presidio de Santa Barbara State Historic Park, 2006. (Photo, Michael Imwalle.)

Ruben Reyes stoking during experimental kiln firing at El Presidio de Santa Barbara State Historic Park, 2007. (Photo, Michael Imwalle.)

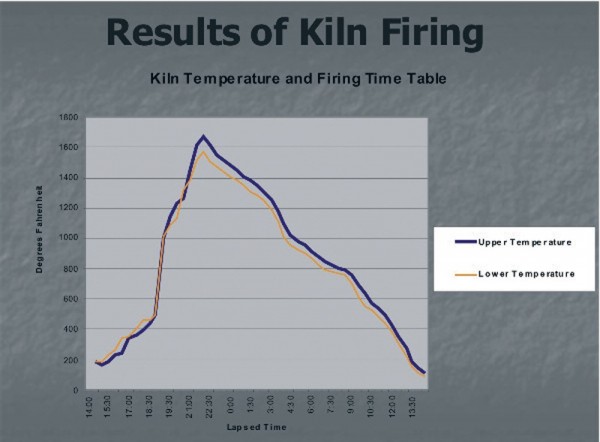

Graph showing the progression of kiln temperatures during experimental kiln firing in 2007.

Presidio demonstration kiln with bisqued vessels after initial experimental firing in April 2006. (Photo, Michael Imwalle.)

Ruben Reyes adjusting the flue on California’s only wood-fired, Spanish colonial–style updraft kiln, El Presidio de Santa Barbara, June 2006. (Photo, Michael Imwalle.)

Anacapa School students Joshua Figueroa, Aubrey Cazabat, and Wishiah Roper screening clay for ceramic production, 2007. (Photo, Michael Imwalle.)

Ruben Reyes demonstrating wheel-thrown pottery for schoolchildren at El Presidio de Santa Barbara State Historic Park’s “Early California Days” living-history program, 2007. (Photo, Michael Imwalle.)

A group of green and bisque-fired ceramics ready for experimental firing at El Presidio de Santa Barbara State Historic Park, 2007. (Photo, Michael Imwalle.)

San Diego Polychrome mayólica plate fragment, Puebla, Mexico, 1750–1835. Tin-glazed earthenware. (Photo, Michael Imwalle.) The tin-glazed ceramics of the Spanish colonial world are very colorful. This fragment with a sunflower design was recovered from archaeological investigations at El Presidio de Santa Barbara in 2009.

San Elizario Polychrome mayólica plate fragment, Puebla, Mexico, 1750–1830. Tin-glazed earthenware. (Photo, Michael Imwalle.) This was recovered at El Presidio de Santa Barbara.

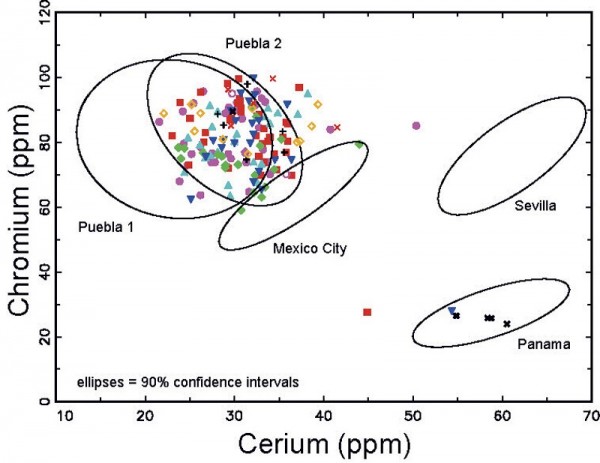

Plot of cerium vs. chromium showing the association of the California mayólica samples with the major Mexican production centers at Puebla and Mexico City, the Spanish center at Sevilla/Triana, and the Panama City production in Panama. The ellipses represent 90% confidence intervals. Each symbol represents a different mission, presidio, or pueblo (individual sites not identified). (M. James Blackman, Smithsonian Institution.)

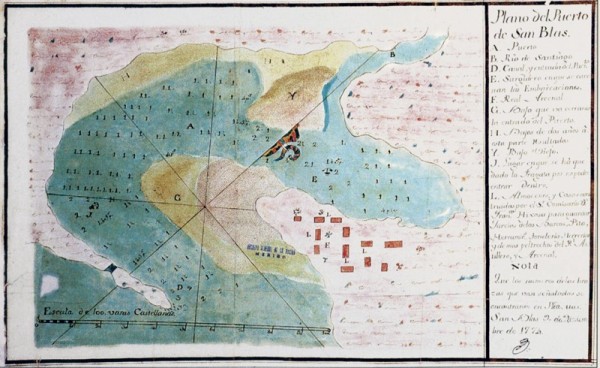

Eighteenth-century plan of the port and naval supply depot at San Blas, Mexico. (Courtesy, Archivo General de Nación, Mexico City, Mexico.)

Mayólica reproductions from Mexico. (Left) Puebla tradition, twentieth century; (right) Aranama tradition. (Photo, Michael Imwalle.)

Partially reconstructed Aranama Polychrome, 1750–1800, and Puebla Blue-on-white, 1750–1850, Puebla, Mexico. Tin-glazed earthenware. (Photo, Michael Imwalle.) These fragments are from archaeological excavations at Soledad Mission.

The dining room (comedor) of the commandant’s quarters (comandancia) at El Presidio de Santa Barbara State Historic Park in Santa Barbara, California, 2009. (Photo, Michael Imwalle.)

Replicated soup plate (sopero) on potter’s wheel in Pottery Shop at La Purísima Mission near Lompoc, California, 2006. (Photo, Michael Imwalle.)

Ruben Reyes wore a protective mask and gloves while mixing the tin glaze for the 2007 experimental glazing and painting project conducted at El Presidio de Santa Barbara State Historic Park in Santa Barbara, California. (Photo, Michael Imwalle.)

Iron-oxide concretions excavated on the grounds of El Presidio de Santa Barbara State Historic Park were manually ground into fine powder for use as a black or brown pigment in oxide paints for decorating glazed ceramics. (Photo, Michael Imwalle.)

Dr. Russell Skowronek grinding, mixing, and weighing oxides for paints, 2007. (Photo, Michael Imwalle.)

Composite of mayólica patterns reconstructed by Anita Cohen-Williams and Jack S. Williams. (Adapted in 2007 by authors, from “Reconstructing Maiolica Patterns from Spanish Colonial Sites in Southern California,” California Mission Studies Meeting, San Luis Obispo, 2004.)

Mayólica patterns painted by volunteers in 2007 to replicate patterns reconstructed by Cohen-Williams and Williams in “Reconstructing Maiolica Patterns from Spanish Colonial Sites in Southern California.” (Photo, Michael Imwalle.)

Dr. Robert Hoover painting a Puebla Blue-on-white sopero, 2007. (Photo, Michael Imwalle.)

(Left) San Elizario Polychrome sopero (illustrated in Cohen-Williams and Williams, “Reconstructing Maiolica Patterns from Spanish Colonial Sites in Southern California”); (center) San Elizario Polychrome sopero replica painted by Karen Anderson and Toni Clark before firing, 2007; (right) San Elizario Polychrome sopero painted by Karen Anderson and Toni Clark after firing, 2007. (Photos, Michael Imwalle.)

(Left) Replica Tucson Polychrome sopero fired in a sagger; (right) San Elizario Polychrome sopero fired without a sagger, 2007. (Photo, Michael Imwalle.) Note the clear, bright, glossy glaze of the saggered vessel and the dark, dull appearance of the carbon trapped in the unprotected vessel.

Elizabeth Skowronek, our “research assistant,” at the beginning of the project in 2000, holding a 200-year-old escudilla at Mission San Antonio, and in 2010, holding a replicated escudilla. (Photos, Russell Skowronek.) Currently a college student studying engineering, Elizabeth continues to work on aspects of this and related projects.

Two-chamber Spanish-colonial updraft kiln at El Presidio de Santa Barbara State Historic Park during the firing of the mayólica, 2007. (Photo, Michael Imwalle.)

Assortment of mayólica vessels produced during glazing and painting project, 2007. (Photo, Michael Imwalle.)

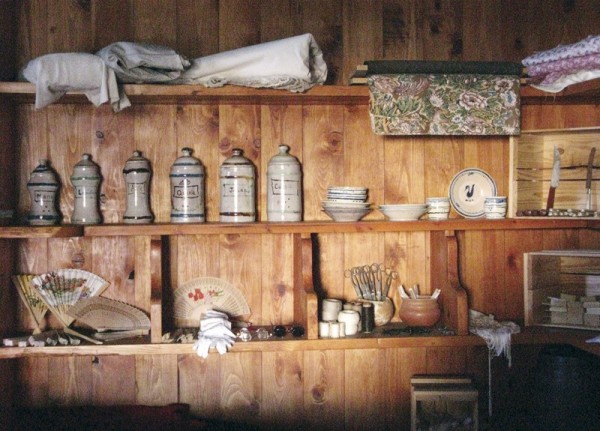

Replicated mayólica apothecary jars on exhibit in the circa-1830s Casa De la Guerra store, Santa Barbara, California, 2009. (Photo, Michael Imwalle.)

Replicated San Elizario Polychrome soperos on edge in the cupboard (second and third row from top) of the comandancia (commandant’s quarters), El Presidio de Santa Barbara State Historic Park, 2009. (Photo, Michael Imwalle.)

For five years (2009–2014) a bilingual exhibition on the California Pottery Project at El Presidio de Santa Barbara State Historic Park explained the processes of pottery fabrication and analysis. (Courtesy, El Presidio de Santa Barbara State Historic Park, Santa Barbara, California.)

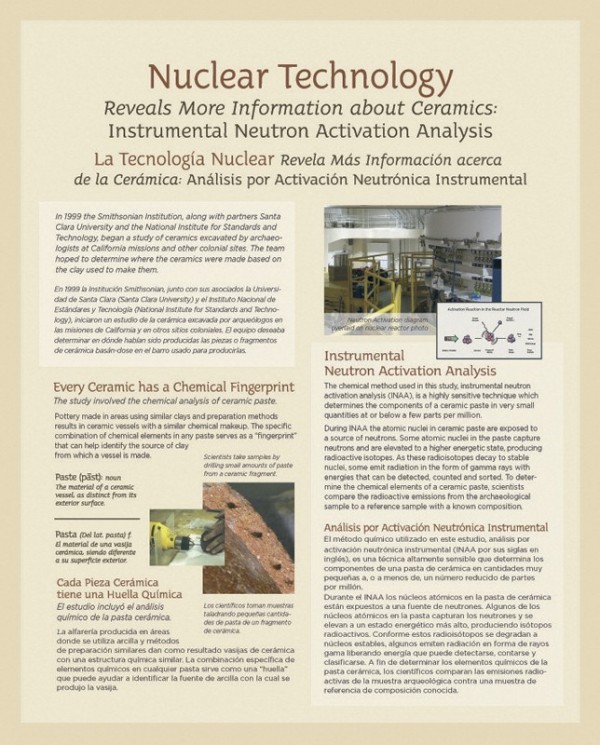

A panel in the exhibition “Ceramics Rediscovered” at El Presidio de Santa Barbara State Historic Park details how instrumental neutron activation analysis can “fingerprint” ceramics. (Courtesy, El Presidio de Santa Barbara State Historic Park, Santa Barbara, California.)

Before the arrival of the Spanish in what was known as Alta California (Upper California) in 1769, ceramics were largely unknown to the aboriginal occupants of the region north of the Los Angeles basin through the San Francisco area (fig. 1). Alta California came under Spanish control as part of the Viceroyalty of New Spain as the province of Las Californias, encompassing an area that included what is now the state of California and other states to the east. The territory came under control of the Mexican government in 1821 and remained so until 1848, when the United States took possession. For the most part, much of the area remained populated by the Native Indian peoples.

The early colonization push by Spanish priests, soldiers, and settlers, however, brought a new ideology, a new social organization, a new economy, and new technologies. One of those technologies was the creation and use of ceramic vessels and terracotta building materials. It was at Mission San Antonio in 1776 that fired tiles were first made.[1] Almost a decade later, on August 9, 1785, it is reported that roof and floor tiles were being produced at the Santa Barbara Presidio, built as one of the territory’s military installations by the Spanish.[2] By the end of the century, buildings from San Diego to San Francisco were roofed and floored with tejas (roof tiles) and ladrillos (bricks) and they were fitted out with ceramic utilitarian, table, and storage wares.

Few researchers have questioned the origin of the pottery. In Alta California, it was thought, potters fabricated plain, unglazed pottery at a handful of production locales, so most assumed that the glazed ceramics were imported from Mexico. This assumption has a basis in documentary evidence dating from the 1790s, when Father Fermín de Lasuén, president of the California missions, arranged for a number of artisans and craftsmen to be recruited from Mexico to teach their skills to the residents of the Spanish missions in Alta California.

Modern historic sites in California that predate the annexation of the area by the United States in 1848 are limited to about one hundred adobe block structures associated with the few score ranchos, three pueblos, four presidios, and twenty-one missions of the Spanish and Mexican era. Missions, operated by the Franciscans, were the nexus for the conversion and transformation of indigenous peoples into loyal supporters of the Spanish crown. These were largely self-sufficient agrarian communities that would become the primary suppliers of foods and goods to civilian pueblos and military presidios. Pueblos were agrarian civilian communities whose populace was largely made up of retired soldiers and their families. The men served as the colony’s reserve militia and their households and ranches helped supply the presidios. Presidios were garrisoned forts that served as the center for the administration of civilian, Indian, and military affairs and justice. They were dependent on Mexico, the missions, and the pueblos for supplies and labor.

With such notable exceptions as the Santa Barbara Presidio and the Misión La Purísima Concepción de María Santísima (Mission of the Immaculate Conception of the Most Holy Mary, hereafter La Purísima Concepción), which are operated as California State Historic Parks, most of the other extant historic sites are administered by municipalities or the Roman Catholic Church.

In the first two named sites, reconstructed buildings are often bereft of accoutrements that would provide texture to visitors’ experience there. At La Purísima Concepción, a reconstructed pottery “shop” is filled with crudely made vessels fabricated from commercially purchased clay. (One visitor was heard to remark, “I made better stuff in kindergarten.”) Historical interpretation at these and other sites is frequently haphazard, with archaeologically recovered broken or dented artifacts and donated objects of unknown provenience displayed next to new items purchased in Tijuana or other Mexican cities because they “look close enough.” This situation might be due to ignorance of the material culture of the era or perhaps to the erroneous belief that there are no differences between the objects of the past and modern Mexican-made items.

A darker interpretation could stem from a shallowly hidden scorn for the Californios and other Hispanic residents of California, be they Christianized Indians or Mexicans, who are often thought of as living in quaint simplicity enhanced only by products brought from Europe. Showing largely empty interiors with few and poorly made, dirty, or damaged objects suggests that California’s real potential was realized only after its annexation by the United States of America.

As a way to counter this message, the California Pottery Project was initiated in 1999 by researchers from Santa Clara University and the Smithsonian Institution to study ceramic supply, exchange, and production in Alta California, turning Hispanic California’s historic sites into learning nodes that celebrated both the richness of the region and those who lived there. Using the analytical technique of instrumental neutron activation, this project determined that plain and lead-glazed ceramics were produced from San Diego to north of San Francisco.[3] With this information, members of the research team—consisting of archaeologists, a chemist, and a master potter—joined the Santa Barbara Trust for Historic Preservation to examine the history and firing technologies associated with the making of these ceramics. The investigation focused on the materials and techniques used and sought avenues to make the information available for the interpretation of historic sites. By working closely with the master potter we were able to shed light on past manufacturing practices and also produced ceramic vessels for interpretive purposes for institutions that cooperated with the project. Because this research has found in Hispanic California a high level of technological and artistic sophistication, it needs to be shared not only with professionals but with the public as well.

Historical Background

In the last third of the eighteenth century Alta California was occupied by the Spanish. From the modern Los Angeles Basin northward they encountered the nonceramic-making hunters, gatherers, and fisher folk known as the Chumash. It was among these peoples that the Spanish established the presidio at Santa Barbara (1782) and the missions of San Luis Obispo (1772), San Buenaventura (1782), Santa Barbara (1786), La Purísima Concepción (1787), San Fernando Rey de España (1797), and Santa Inés (1804). Chumash settlements extended over seven thousand square miles of territory, including two hundred miles of coastline and extending inward to the San Joaquin Valley.[4] There were also settlements on the four Channel Islands off the coast of Santa Barbara: Anacapa, Santa Cruz, Santa Rosa, and San Miguel.

Prior to the arrival of the Spanish, the Chumash made their cooking and storage vessels out of basketry, wood, and stone. Coiled baskets were employed for food preparation, seed storage, and trays; twined baskets were used for “fishing, seed beating, straining leaching and water storage.”[5] Baskets for water storage typically were lined with tar to prevent leakage.[6] A variety of utensils for food preparation and eating were made of wood, and carved and smoothed wooden vessels were utilized as serving bowls and storage jars.[7] Cooking bowls and frying pans were made of steatite;[8] other stones were used for grinding implements and surfaces.[9] One oral history account suggests that, before the arrival of the Spanish, the Chumash used red-clay vessels to hold tar.[10] When studying the nearby Chumash village site of Muwu, however, Holly Love and Rheta Resnick found that Chumash did not make pottery prior to the establishment of the mission.[11]

Trade or exchange might seem to be a plausible explanation for the similarities among mission-made ceramic wares, but in fact the issue is somewhat problematic. Most of the trade among the missions, pueblos, and presidios would have been overland, since most of the sites were located inland without waterways connecting them. This would have required ceramics to be moved long distances on dirt roads and in carts or mule trains—the only transportation available at that time. Breakage would certainly have been an issue, especially with fragile, low-fired wares, so to supply an entire mission population with ceramics would have been difficult. It would have been far more economical for missions to produce their own utilitarian wares rather than import them. It is true that some ceramics were imported from Mexico, but based on recovery contexts at presidio and pueblo sites those pieces appear to be exotic items intended for use by colonists and soldiers. This is obviously not the case with low-fired, unglazed earthenwares.

Robert Hoover and Julia Costello noted in their report on the excavations at Mission San Antonio that inter-mission trade in roof and floor tiles would have been impractical due to the bulk and relative fragility of these earthenwares (a single roof tile can weigh 8–15 pounds). Moreover, to meet growing demand it would have been necessary for each mission to possess the technology to fire its own tiles. (Mission-made pottery, ladrillos [bricks], and tejas [tiles] are all earthenwares fired above 660°C.[12])

Once the technology was in place, skills were needed to actually produce the pottery. The artisans and craftsmen recruited by Father Lasuén in the 1790s to teach these skills were distributed among different missions throughout Alta California. Beginners from missions that had no teachers were sent to those that did in order to learn specific trades.[13] Francis Guest’s biography of Father Lasuén states, for example, that in 1796 Santa Clara sent “neophytes” to Monterey to learn tailoring and pottery making from Mexico-born Mariano Tapia.[14] A letter dated February 5, 1799, refers to “Maestro Jose Antonio” finding “good mud” from which he was able to make large and small pieces of pottery at Mission San Francisco.[15] With the aid of these instructors and master potters, ceramic know-how was rapidly transferred across the province.

The Jurisdiction of the Santa Barbara Presidio

On April 21, 1782, the Santa Barbara Presidio was established. Within the garrison’s jurisdiction would be the missions at San Buenaventura, Santa Barbara, La Purísima Concepción, San Fernando Rey de España, and Santa Inés. Within two years adobe buildings were being erected; redwood beams for the structures were shipped from Monterey.[16] In 1786 workers from San Gabriel came to Santa Barbara to “manufacture roof tiles and 20,000 adobe bricks.”[17] While ladrillos and tejas were being produced on location, documentary evidence suggests that ceramic goods such as mayólica were imported from other parts of New Spain.[18]

Mission San Buenaventura was founded on March 31, 1782, and within five years adobe structures were being erected; by the mid-1790s they were sporting tile roofs.[19] In 1810 one of the buildings was used specifically as a pottery.[20]

In 1786 Mission Santa Barbara was founded adjacent to the ranchería Tay-nay-an.[21] The following spring, adobe structures began to be erected that were covered with fired tiles in 1788. In 1808 a building for the “manufacture of pottery” was built adjoining the church.[22]

La Purísima Concepción, the eleventh mission established in Alta California, was founded in 1787 near what today is the city of Lompoc.[23] Within a year, the mission’s original buildings of wood and thatch began to be replaced with adobe structures, and in 1790 a tile kiln was constructed.[24] For two decades the mission stood at this site until a large earthquake in 1812 destroyed the original complex.

In 1797 Mission San Fernando Rey de España was founded on the Encino River in what is today the Los Angeles Basin, and in less than two years tile-roofed adobe structures were being constructed at the site.[25]

In 1804 Mission Santa Inés was established, the last community founded in the Santa Barbara Presidio. Within months of its establishment, adobe structures were under construction and they were roofed with tiles the following year.[26]

The documentary record thus indicates that tiles were being made at every community under the jurisdiction of the Santa Barbara Presidio, and evidence also suggests that pottery was being made at some of these sites. To determine where these ceramics were being fabricated, Instrumental Neutron Activation Analysis (INAA) was employed to determine their chemical composition. INAA is an analytical technique that has been used successfully to identify the source of ceramics in many parts of the Americas and elsewhere.[27]

We began in 1999 with a feasibility study involving 150 ceramic samples from Mission Santa Clara de Asís. It was found that some of the potsherds are chemically identical to bricks and tiles found at the site, which suggests that the same source of clay was used for both and that both were made at Santa Clara. Subsequent study of the pottery from within the entire jurisdiction of the San Francisco Presidio using this technique demonstrated not only the fabrication of unglazed tiles, bricks, and ceramics but also lead-glazed ceramics.[28] Would the Santa Barbara jurisdiction, several hundred miles south of the San Francisco Bay area, reveal the same trends?

Instrumental Neutron Activation Analysis (INAA)

Ceramic earthenwares associated with Alta California sort into three categories: plain, lead-glazed, and tin-glazed. At a cursory level, it appears that striking similarities exist among earthenwares found hundreds of miles apart. Prior to our project it was commonly thought that all glazed ceramics were imported from Mexico. As for the ubiquitous plain ceramics, two general schools of thought were favored. One held that similarities in form were the result of one, or a few, missions making the ceramics and trading them to other missions. The other held that each mission made its own earthernwares but used forms following a Spanish colonial “cultural template.”

The issue of local/nonlocal manufacture was addressed through the use of INAA to characterize the paste composition of earthenwares, including both tableware and architectural components. Ideally, a single clay source would be identified and matched to the ceramics and earthenwares, which would confirm local production of both pottery and architectural earthenware. Of course, after more than two centuries the identification of the clay source(s) used to make ceramics at a site becomes difficult to identify. Lacking that essential information, we used the premise that since inherently heavy ladrillos and tejas were locally produced and consumed, their composition would be indicative of locally mined clay. INAA was used for comparing the pottery and the ladrillos and tejas. The technique permits many elemental constituents of a ceramic paste to be determined simultaneously with good precision, several at or below the parts-per-million level. This level of sensitivity has led to precise distinctions being made among archaeological ceramics that were manufactured by closely located sites, and even to identifying the products of particular workshop.[29]

Within the jurisdiction of the Santa Barbara Presidio, INAA of architectural earthenwares revealed local manufacture of tejas and ladrillos at Missions San Buenaventura, Santa Inés, La Purísima Concepción, and Santa Barbara. A similar analysis of plain and glazed ceramics from Missions San Buenaventura and Santa Barbara and the Santa Barbara Presidio showed that all tin-glazed ceramics originated from Puebla, Mexico. Other lead-glazed ceramics derived from another location, currently unknown but presumed to be in Mexico. The remaining lead-glazed and plain ceramics matched the elemental chemical signatures derived from the tejas and ladrillos of the respective sites. It soon became clear that pottery manufacture was widespread throughout Hispanic Alta California.

Using the abundance of chromium, zinc, and cesium as reference, the graph in figure 2 illustrates separations among the ninety-two bricks and tiles from the Santa Barbara Presidio and mission and the Missions Santa Inés and San Buenaventura. Inspection of the data set reveals that the Santa Barbara and Santa Inés mission subregions each has a distinctive chemical signature, while the San Buenaventura bricks and tiles divide into two closely related chemical groups. The bricks and tiles of La Purísima Concepción, however, display a notable dispersion as observed in the graph; in fact, their data stands in contrast not only to the data from the other locations in the jurisdiction but also to that obtained for other mission sites in California. We will return to this topic later.

After initially determining that the tiles and bricks from each of the mission sites (La Purísima Concepción excepted) tended to have distinctly different chemical signatures, the locally manufactured architectural ceramics groups were compared with the compositional data obtained for the plain earthenware pottery recovered. The combination of these two data sets delivers additional clarity of local compositional signatures and provides evidence that earthenware pottery was manufactured at each mission.

As can be seen in figures 3A and B, almost all samples of plain earthenware pottery recovered at the Santa Barbara Presidio and mission lie within a 95% confidence ellipse for the local Santa Barbara compositional group that was initially defined by the Santa Barbara architectural ceramics. Only four of the fifty-five analyzed display significant deviation from the chemically defined Santa Barbara compositional group. The plain earthenware from Mission San Buenaventura was compared to the architectural ceramics from San Buenaventura, the Olivas Adobe (built on land originally owned by Mission San Buenaventura), and the Santa Barbara compositional group. The zinc-versus-scandium plot in figure 3A shows that six of the twelve pottery samples are associated with San Buenaventura compositional group 1 and none with the smaller group 2. Two plain earthenware samples are associated with a single one from Santa Barbara and four additional samples fall squarely within the Santa Barbara group. This latter apparent association is an artifact of binary plots. When zinc is plotted versus a third element, chromium (figure 3B), the samples are shown to fall outside the Santa Barbara group.

While one half of the San Buenaventura earthenware pottery samples are compatible with one of the two local architectural ceramic groups and are very likely of local manufacture, the other half is not clearly associated with known San Buenaventura clay resources. This does not imply that the four samples, with quite similar composition, were not made at San Buenaventura, as plain earthenwares from San Francisco and Santa Clara also have two distinguishable compositional groups. It may merely indicate that another clay source was used to make the pottery.

Figure 4 illustrates patterned dispersion of the analyzed tiles, bricks, and earthenware for Santa Barbara, Mission Santa Inés, and the subgroups or clusters observed within the La Purísima Concepción data. Only the ceramic materials from Santa Barbara and the ceramics from Santa Inés, in which bricks and tiles predominate, are sufficiently numerous to allow for the assessment of likelihood of group membership. Ellipses have been added to the plot to indicate a 95% group-confidence interval about the Santa Barbara and Santa Inés ceramics.

Strong separation is observed for the Santa Barbara and Santa Inés groups, with the earthenware pottery associated with the architectural ceramics from each site. One of the most notable aspects of the graph, however, is the fragmentation of the La Purísima Concepción materials into four small clusters. Three of the clusters appear to have higher zinc concentrations than the Santa Barbara or Santa Inés ceramics, but one cluster overlaps the Santa Barbara materials, as we also noted for some of the San Buenaventura ceramics. The divergence into multiple clusters among the La Purísima Concepción ceramics is at variance with the situation encountered at other mission and presidio locations in California, which requires explanation.

Although too few in number to be subjected to rigorous statistical evaluation, the La Purísima Concepción materials were labeled clusters 1 through 4 and the textural characteristics of the bricks, tiles, and earthenware against these groupings were evaluated: notable differences were found. Clusters 3 and 4 were found to be populated mainly by bricks and tiles that were made from clays mixed with poorly sorted coarse sands, all of which were fully oxidized during firing. The original mission was located in the floodplain of the Santa Rosa (now Santa Ynez) River. The compositional heterogeneity of the bricks would be consistent with the use of raw materials taken from a high-energy floodplain. In contrast, bricks and tiles in clusters 1 and 2 were of a finer texture, better sorted, and remained gray (not showing signs of extensive oxidization). When recovery locations were noted for the samples, all of the samples in clusters 3 and 4 were from the original mission (La Purísima Concepción I). After the first mission’s destruction by earthquake in 1812, it was rebuilt to the north in Los Berros Canyon, on land more level and away from the influence of damaging floods. The new location was favorable in terms of building materials and fertile farmland, and it also offered different sedimentary resources for the manufacture of architectural ceramics—ones not characterized by the coarsely mixed depositions of the river. All of the samples in clusters 1 and 2 were recovered from the second mission (La Purísima Concepción II).

Interestingly, two bricks recovered from the second mission were coarse, fully oxidized, and matched cluster 3. Based on research conducted by Julia Costello, what remained of La Purísima Concepción I following the 1812 earthquake was salvaged and used to construct the new mission.[30] The two analyzed samples of oxidized, coarsely textured bricks from the new location can be explained as an example of the reuse of materials. Thus the paste composition is found to be better patterned than it would first appear from looking at figure 4; it just takes a historical perspective to understand why.

Some samples of La Purísima Concepción cluster 2, composed of plain wares and architectural ceramics, can be seen to overlap in the chromium–zinc plot with the Santa Inés compositional group. Although separated when other elemental combinations are used, some compositional similarity is to be expected because the site of La Purísima Concepción is located only eighteen miles from Santa Inés. In addition, most of the Santa Inés group is composed of bricks and tiles, and the lack of refinement of the raw clay during manufacture gives rise to relatively heterogeneous ceramics. Even given the similarity to Santa Inés, it is reasonable to consider the few samples of La Purísima Concepción cluster 2 as representing a local composition for the mission in Los Berros Canyon. But what of La Purísima Concepción cluster 1 that is observed to lie within the confidence interval about the Santa Barbara materials? Does it really have the same chemical “fingerprint”? In figure 5 the question of overlap is resolved when the data is graphed relative to the scandium and zinc concentrations, revealing that all of the La Purísima Concepción ceramics are shown to lie outside of the 95% confidence interval for the Santa Barbara compositional group.

We have no ready explanation for the chemical differences between La Purísima Concepción clusters 1 and 2. Perhaps cluster 1 presents slightly sandier textures, but with so few samples one should be hesitant to draw any conclusions or even state a generalization. Handmade and wheel-thrown examples occur in both groups. The geology in the area is complex, with a long history of folding and faulting sedimentary formations and the presence of sandstones and igneous rock.[31] It is possible that clusters 1 and 2 both reflect the use of local resources that differ in significant ways.

In summary, each of the missions or mission-presidio combination within the Santa Barbara jurisdiction is found to have bricks, tiles, and plain earthenwares manufactured from local resources that are chemically distinguishable. The more complex relationships found in the San Buenaventura earthenware pottery are yet to be clarified, whereas the multiple clusters within the La Purísima Concepción ceramics are largely explained by a historical process of building-material reuse. Thus for building and plain-ware utilization, self-sufficiency was characteristic of the individual missions within the Santa Barbara jurisdiction, as it was for those of San Francisco.

Glazed Wares

Investigation of the lead-glazed pottery represented an additional dimension to our research. The use of lead-based paint applied decoratively to pottery, however, was used in the American Southwest as early as the thirteenth century. The Spanish introduction of a lead-based glaze represented a new technology, as many types of lead glazing applied to earthenware were developed in the sixteenth century along with new advances in kiln construction.[32] A common folklore was that the complexity and expense involved in the production of lead-glazed pottery was beyond the capability of the early mission potters, and sources therefore tended to be attributed to Mexican manufacture that were subsequently traded to the missions along the California Camino Real. But where in Mexico were the glazed wares produced, and how many different manufacturing locations were involved? In order to address these questions, we essentially had to characterize the glazed-pottery production of sites throughout Mexico. Special sampling attention was given to those locations that are known from documentary sources as having been involved in the production and trade of glazed wares.

The investigation is ongoing, with reasonably good characterization of the major production areas of Mexico, Puebla, Oaxaca, and Aguacalientes, among others. The analysis of the approximately 500 glazed wares associated with the California missions has failed to show that the great ceramic producing centers of Mexico City or Puebla were the manufacturing sources of these wares. More than 160 of those analyzed came from a single source, the location of which is unknown. We previously demonstrated that some glazed pottery recovered from the California missions was locally made, usually having a dark reddish glaze.[33] Was this also true for the missions of the Santa Barbara jurisdiction?

Figures 6 and 7 summarize our findings for the latter, where only a single sample, possible evidence for local production at Santa Barbara, lies within the 95% confidence ellipse associated with sites in the jurisdiction. The other lead-glazed ceramics are seen to be significantly low in their chromium values. The result, therefore, is similar to that of other missions in California: the source for the glazed ceramics is unknown but it does not appear to be in Mexico City or Puebla.

Brick and Tile Making on the Alta California Frontier

If there is a ubiquitous artifact on the Spanish/Mexican sites of Alta California it would be fragments of architectural earthenwares—bricks and tiles (fig. 8). Tons of these objects have been excavated and curated or sometimes thrown away or sold because they were seen as un-diagnostic by archaeologists and curators. Beginning in 1999, however, our research demonstrated that these artifacts could play an important role in the interpretation of ceramic production, supply, and exchange. Using INAA, their chemical make-up could be identified, which in turn would provide evidence for localized procurement of clays for the production of pottery. Later, the study of the technologies associated with the creation of these architectural materials provided new insights into their significance in the world of the California frontier.

A tile begins as a mixture of clay and water mixed to the proper consistency in order to hold its shape while drying. A rectangular or square wooden mold dusted with sand serves as the receptacle for a dollop of the clay. In modern Mexico the molds can be made of metal matching the tapered form of the tiles. Once in the mold, the clay is pounded to remove trapped air and the excess is cut away with a wire.[34] It is then smoothed by hand or with a piece of wood or metal.

Just before the United States entered World War II, historian George Tays was involved in the restoration of Mission La Purísima Concepción. While there he observed the Civilian Conservation Corps making roof tiles (fig. 9) and noted, “the mud had to be very thick and almost dry, and this was laid over the mould.”[35] In order for the tiles to be removed from the molds during the manufacturing process the clay has to be stiff enough to retain its shape (fig. 10). Therefore it must be forcibly pressed into the brick or tile molds (fig. 11). Our experiments in the making of tiles showed his observations to be true when those formed with wet clay tended to collapse under their own weight (fig. 12).

When properly made, unfired bricks are tipped out of their molds to dry. In Alta California the floor tiles or bricks were 11 inches square and 2 inches thick. Roof tiles (tejas) were about 24 inches in length, the larger end 10 inches across and the narrower end 8 inches.[36] Wet tiles could weigh as much as 25 pounds.

On October 30, 1800, more than two centuries ago, Fathers Estévan Tápis and Juan Cortés of Mission Santa Barbara reported on the workload of the tejeros: “Sixteen young men, and at times as many more middle-aged men, with two women who bring the sand and straw, make 500 tiles a day. The troughs with the clay are close by and always filled. These neophytes accomplish their task before eleven o’clock in the morning. . . .”[37] Later in the same document we learn that tile making at the nearby Santa Barbara Presidio was much more onerous: “[T]hey had made 500 tiles, but had to dig out the clay, throw it into the troughs, and draw water from a well fifteen yards deep or from a laguna some distance away. Moreover, they had to fetch the sand from the beach one-eighth of a league away, procure the straw, [and] knead the clay . . . .”[38]

Knowledge about the activities associated with traditional Mexican brick making is informed through the work of ethnographers.[39] From them we learn that brick making requires strength, endurance, and awareness of local climate conditions, as well as experience in manipulating the clays during the sequential steps of making, drying, and firing of brick. Master brick makers (maestro ladrilleros) had to know the material perfectly to fire it at the proper temperature, the most important procedure in the fabrication of bricks. Badly fired bricks were not simply useless, they were also a waste of labor and fuel; they could be dangerous if used, as a building might structurally fail.

Brickyards require not only a water and clay source, known as a pozo or barranco, but also sufficient room for the storage of fuel and for molding, drying, and burning the bricks and tiles in a kiln (obrador, cocedor, or horno). Ideally, brick works stand in close proximity to a construction site, since transporting these heavy items is expensive. In Alta California two hundred years ago, the only practical means of moving fuel to the brickyards and the finished earthenware construction materials to the building site was via an oxcart known as a carreta.[40]

Mariano Tapia is the only documented historically known tile maker in Alta California.[41] Mardith Schuetz-Miller, however, has identified twenty-two Indian artisans as masons.[42] Researching the Mexican “brick culture” in Texas, Scott Cook reviewed the 1850 U.S. Census and noted twenty-five references to brick masons but no brick makers in this region bordering the Rio Grande that was recently annexed from Mexico.[43] He believes that brick masons were also brick makers. Perhaps these individuals were, like Mariano Tapia, brick makers (ladrilleros) and tile makers (tejeros).

Modern Insights on Brick and Tile Making

According to the account of Tápis and Cortés, a tile of wet clay weighed 25 pounds, which, if correct, meant the weight of clay needed to produce 500 roof tiles would be approximately 6.2 tons. Master potter Ruben Reyes, unwilling to take this report at face value, broke down the production of the tiles into revealing numbers. If all of the work was done by sixteen workers, each would have had to wedge 781 pounds of clay and then create 31.2 tiles within a six-hour period. If all of the work—digging, crushing the clay, and cleaning it—was done in a single day, without rest, problems would have arisen during the drying and firing steps. Reyes prepared clay from scratch with a team of four potters using modern tools. In six hours they were able to prepare about one ton of clay. Keep in mind that all they did was move the fifty-pound bags of clay from a truck using a forklift, open the bags, dump the contents into a mixer, and then remove the mixed clay. Clearly, Tápis and Cortés had either inflated their numbers or failed to report the true number of workers who made 500 tiles in a day (fig. 13).

Brick and Tile Kilns

Two types of updraft or “clamp style” kilns (one permanent, the other temporary) are associated with brick and tile making. Rectangular or round in shape, they have a fire chamber or tunnel for stoking and a chamber for the unfired brick. Their difference is in the outer walls. Permanent ones are built of fired bricks that are mortared together, whereas the temporary ones have walls made of unfired bricks or adobe and are sometimes known as Scotch or clamp kilns.[44] In the latter case, the kiln is dismantled after firing and the fired bricks are removed. Scott Cook believes that this sort of kiln was in use in the colonial period and diffused throughout New Spain (fig. 14).[45]

Updraft kilns in Mexico today are typically small, with a chamber measuring one meter square, and are fired with wood.[46] Larger kilns, with 4 x 4–meter chambers capable of holding 3,000 roof tiles, are also reported (figs. 15, 16). These are sometimes fired with wheat straw. Temperatures with this fuel can reach 1920°F (1050°C).[47] A kiln of this variety was employed during restoration of Mission San Miguel in the early 1940s (fig. 17). A similar kiln was used by Redwind, a Native American community in San Luis Obispo County, to fire brick and tile during the early 1980s (fig. 18). The Redwind kiln was constructed of unfired adobe blocks. The first courses of adobe blocks were alternately placed on their sides to form the firing chambers (fig. 19).

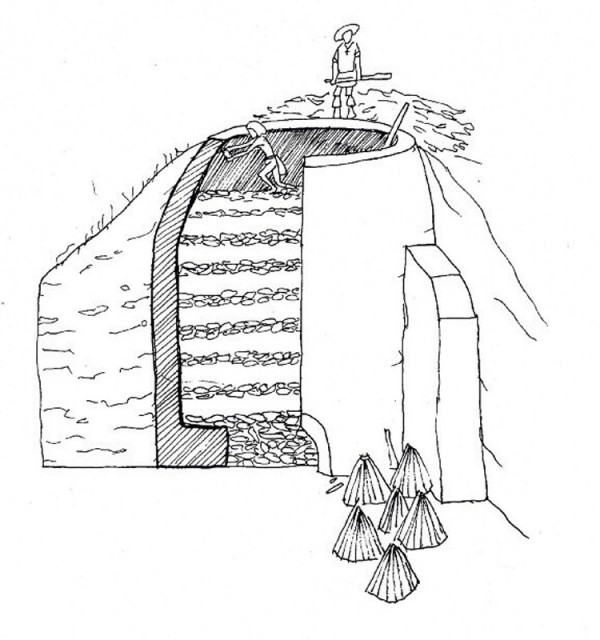

Circular “volcano-style” or “open-top” kilns were also used in Alta California.[48] The volcano-style kilns are similar to those described in England as “bottle kilns,” which are characterized as having restricted necks or flues.[49] Archaeological evidence of such a kiln has been documented at Mission San Juan Capistrano.[50] It has been suggested that this type of kiln served a dual purpose by also functioning as a lime kiln (fig. 20).

Open-top circular brick and tile kilns were the most common tile kilns in use in Alta California. They had straight or vertical walls and an open top. Loaded kilns were covered with tile wasters or adobes blocks to aid in the retention of heat during firing. In contemporary Mexican tile kilns of this variety, sheets of corrugated metal are often used to close the tops of the kilns during firing. Because the top was not sealed, bricks on the bottom of the chamber would often vitrify while those on the top remained unfired. It was not unusual for more than twenty-five percent of the bricks to fail during firing in these kilns.

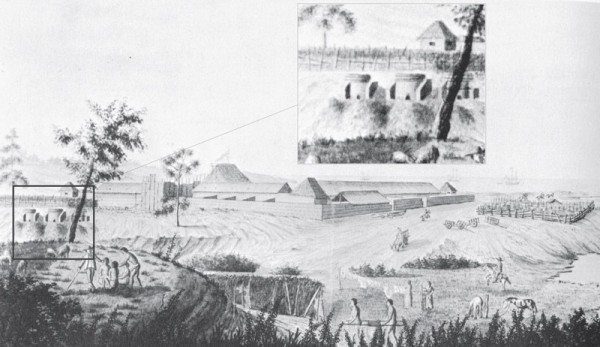

Two examples of open-top circular kilns have survived at Mission San Luis Rey (fig. 21). In José Cardero’s 1791 sketch of the Monterey Presidio, kilns very similar to the larger of the two Mission San Luis Rey kilns can be seen (fig. 22). Circular kilns were also used to fire roof tiles during the 1920s restoration of San Bernadino Asistencía of Mission San Gabriel (fig. 23).

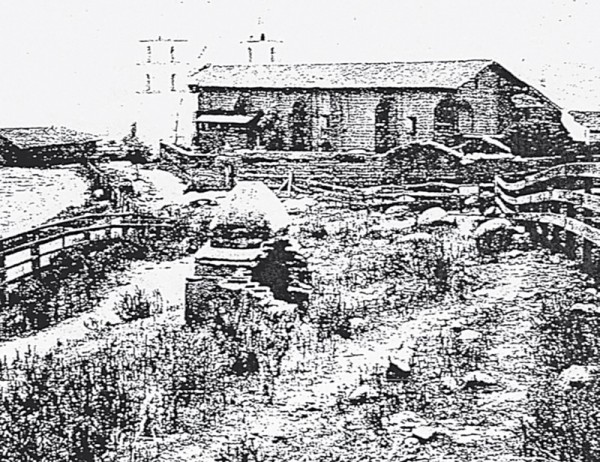

Archaeological evidence of a circular tile kiln was identified by archaeologist M. R. Harrington at the site of Mission La Purísima Concepción in 1940 (fig. 24). The base of a circular kiln was excavated at the foot of a slope suspected of being the source of clay for tiles. It is also located near the building identified as the tile shop (fig. 25). Although this feature was recognized as a tile kiln by Harrington, for some reason park managers later decided to interpret it as a tallow vat (figs. 26, 27).[51] Harrington’s field notes clearly contradict this interpretation. The kiln also differs in scale and design from the nearby tallow vats.

A plan map dating from 1833 of the grounds of Santa Barbara Mission shows four circular structures northwest of the mission quadrangle. The largest of the four features was probably a threshing floor, but the three smaller ones were tile kilns.[52]

In the 1930s Franciscan friars drew a detail of the tile kilns during their survey of the Santa Barbara Mission water system.[53] These kilns were used to fire the tiles used to line the miles of aqueducts that carried water from the Mission Canyon and Rattlesnake Canyon dams to the mission. While not specifically labeled “tile” kilns on the plan, their placement near the quadrangle and away from the pottery suggests they were used to fire bricks and tiles.[54]

Mission San Antonio de Padua’s Brick and Tile Kiln

A groundbreaking study of brick and tile kilns in Alta California was written by Julia Costello based on the partial excavation of a kiln at Mission San Antonio.[55] Her research identified it as a clamp-style single-chamber kiln.[56] In 2006 an operational model of this kiln (1/10th scale) was built based on the published archaeological plan maps of the structure to test her conclusion (fig. 28). Experiments with that model now suggest that it may have been a two-chamber kiln.[57]

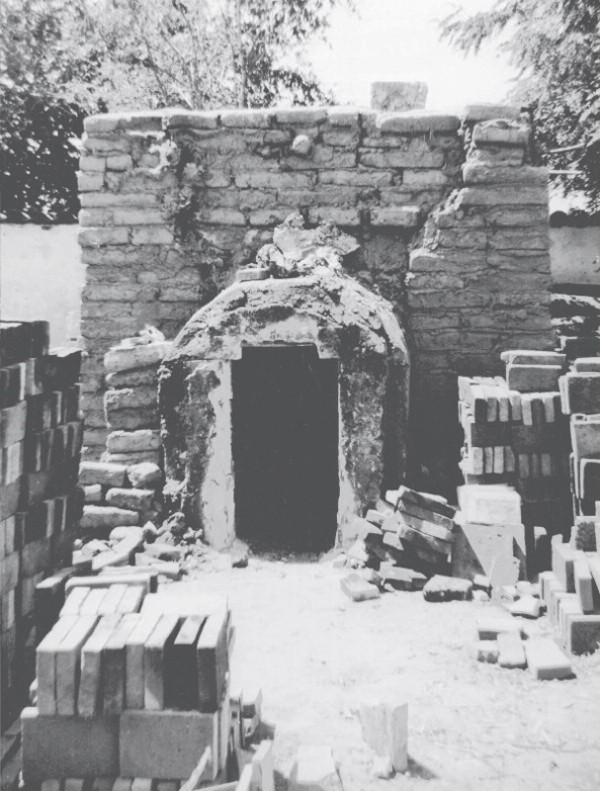

The replication of the kiln has helped to clarify operational details of this poorly understood technology. The excavated kiln structure measured 13 x 7 feet and, based on the excavation plans, had a slanted or “cockeyed” entryway (fig. 29). If this was the original configuration of the kiln, the odd shape of the doorway would not have been conducive for stacking and firing. After the kiln was abandoned, the structure was likely adaptively reused and modified with a rebuilt doorway. Had this been a single-chamber kiln it would have been easy to load, but stoking the 13-foot chamber from a single opening would have been impossible. Single-chamber kilns that large are usually stoked from more than one source point. Based on this reasoning, it appears that the kiln was a two-chamber, open-top updraft kiln. As found in the 1976–1977 excavation, there were columns of fired brick embedded at regular intervals within the adobe walls, which provide support for this assessment. These columns are the remnants of arches that once spanned the structure. The arches formed a brick grate that served as the floor for the second chamber (fig. 30). The kiln at La Purísima Concepción has such a grate (figs. 31, 32). Updraft kiln such as these were historically built in Spain and New Spain and continued to be built by traditional potters, ladrilleros, and tejeros in Mexico into the 1970s.[58]

Our knowledge of ceramic production technologies on the Alta California frontier will continue to grow through ongoing experimentation and research using both working models and full-sized kilns (fig. 33).

Historic Pottery Production in Alta California

The Franciscan missions built in Alta California were far more than churches for teaching Christianity. They functioned more like modern trade schools in which people learned new technologies and specializations while being immersed in a new ideology, language, social organization, and economy. In the 1790s, the president of the California missions, Father Lasuén, recruited Mexican craftsmen to teach their skills at the missions. Carpenters, millwrights, masons, blacksmiths, tanners, weavers, tailors, painters, potters, and tile makers sailed to Alta California and were dispersed across the province.[59] Priests sent representatives to learn the specific trades and to bring that knowledge back to their own communities.[60]

In Mexico at that time, potters and tile makers were usually men. On the borderlands of New Spain, however, women were the potters, as was true among the Apalachee in Florida and the Puebloan peoples of New Mexico and Arizona, and the Kumeyaay, Gabrielino, and Luiseño peoples of the area south of Ventura, California. While we believe we have found evidence that women continued to make pottery in some of the California missions, men became the primary manufacturers of tiles, bricks, and pottery.[61]

At the missions, Indian men were taught to be potters and masons by craftsmen from New Spain. This explains the observed similarities between earthenwares found across the province.[62] These similarities likely are attributable to the introduction of ceramic technology to central and northern coastal California by the Spanish, and by the possibility that there were relatively few teachers of this trade.

There is documentary evidence of the presence of only two potters in California. One was master potter and tile maker Mariano Tapia from Puebla de los Angeles, Mexico, who arrived in Monterey in June 1795 with a four-year contract to teach his trade but died in November the following year.[63] The other, José Antonio Romero, who was a soldier, filled Tapia’s position in April 1797.[64] Although no Indian artisans have been identified as potters, it is likely that, as in other trades, they were involved in this production.

To better understand the transfer of this new technology and specialization, in 2004 Ruben Reyes, a ceramic artist and master potter, joined the Smithsonian California Pottery Project. Reyes, who holds a graduate degree in the ceramic arts from San José State University and who studied traditional potters in Mexico in 1975, is well versed in the use of the wheel and the identification and preparation of the raw materials for the production of ceramics. He immersed himself in the archaeological literature concerning Spanish and Mexican ceramics and ceramic production.

Reyes was asked to teach Kelly Greenwalt, a Santa Clara University undergraduate major in art and anthropology and a past Smithsonian intern, how to make pottery. Greenwalt had never made pottery before this project (fig. 34), yet in less than forty hours she learned how to prepare clay and make the ceramic forms found in California. This essentially answers the question about who made the pottery—all those who learned the trade. Less certain is the gender of the Chumash potters of the Santa Barbara Presidio jurisdiction. Because potting using the wheel is associated with males in Mexico, an argument could be made that Barbareño (the occupants of Santa Barbara) males were the main practitioners. On the other hand, the prowess of Chumash women as basket makers is well-documented.[65] They may well have participated in the potting process.

Local Pottery

Prior to the Smithsonian California Pottery Project, Julia Costello, Ron May, and Jack Williams pioneered the study of locally made ceramics.[66] Costello and Williams independently examined a collection of more than 1,800 fragments of unglazed ceramics excavated by Donald M. Howard at Mission San Antonio de Padua in 1972.[67] Costello created a formal typology and made measured drawings of diagnostic sherds, while Williams, working from the sherds, extrapolated forms. Both Costello and Williams identified bowls, plates, cooking and storage pots, and griddles known as comales. There are also some storage vessels that bear a resemblance to locally made basketry. Samples of these 1,800 ceramics were chemically analyzed as to their function and method of manufacture, and generally were attributable to categories of vessels for storage, preparation, presentation, and consumption.

Costello, Williams, and most recently Sarah Ginn used the same collection of ceramics excavated at Mission San Antonio de Padua to describe a number of manufacturing techniques, including coiled, paddle and anvil, and wheel-thrown.[68] At Mission Santa Clara more than 60 percent of nearly 400 fragments of pottery recovered from an excavation was wheel-made.[69] The California Pottery Project began studying the manufacturing techniques associated with these ceramics in 2003. This included making radiographs of replicated vessels with known methods of manufacture for comparison with radiographs of archaeologically recovered sherds for discerning fabrication techniques. The project also worked with Reyes to identify other qualitative differences, such as uneven thickness and regularity in form, which could be detected through tactile manipulation or simple observation.

Replicating Vessel Form and Fabrication

Replication began with finding suitable clay deposits for making pottery. While clay is widespread in the region, what matters are its tactile qualities for throwing and modeling. For master potter Ruben Reyes that required test-firing clay samples before large quantities were mined.

Reyes speculates that after the first test, a potter would decide whether blending clay was needed and whether sand, grog, or other organic material was needed to improve the body for the specific use in mind (wheel work, coil, paddle anvil, slab, bricks, tiles). Of course a journeyman potter might be able to take a ball of clay, roll a coil, bend it, decide on the fly what was needed to shorten the testing process, and begin work. The deposit found along Mission Creek near Mission San José was “forgiving” and worked well without adding temper or blending with other clay. Nonetheless, some of the locally made pottery did have added temper.[70]

Mining began with the identification of a suitable clay source. We soon learned the difficulties associated with hand mining and the labor involved with carrying buckets of heavy clay from remote streambeds to a fabrication site (fig. 35). The clay was prepared by breaking it into small particles and adding water (fig. 36). After a few days, when it could be stirred into a creamy slip, it was poured through a screen to clean it of pebbles and organic materials. The now-clean slurry was decanted into a wooden form lined with a cotton sheet, which helped dry the slurry by wicking out the water. Days or weeks later, when Reyes felt the clay had reached its desired consistency, it was wedged or repeatedly folded over. This removed air bubbles and ensured that the clay was consistently mixed. Only then could pottery be made (fig. 37).

Reyes noticed that “aging” could affect how the clay would work. A 50-pound sample of clay from the creek near Mission San José allowed to age for six months was found to work better than expected (fig. 38). A second batch, of about 300 pounds, was processed but was not given any time to age. This time Reyes noted that, “the clay threw fine but one had to work with it much faster and not use much water when throwing it.” Reyes’s observations of modern potters in Concordia, Mexico, helped put colonial production in perspective. In 2007 he watched potters dig and clean the clay in the manner described above. Then small amounts of water were added to the clay before wedging (fig. 39). With an even consistency potters in this small village were able to throw vessels, make vessels on an anvil, or fabricate bricks and tiles (fig. 40). Reyes’s goal was to see if it was possible to create pottery from local clay without the addition of temper. His research gave him a feel for some of the problems those potters might have faced in making pottery. He notes that the process he chose suited wheel work and hand construction. Brick and tile work would have been faster, as the cleaning of the clay was less precise and the clay would not have required the proper consistency for throwing.

Reyes made replica forms using the techniques identified by Costello, Williams, and Ginn.[71] Through the kind cooperation of Robert Hoover, Reyes was able to examine the collection of materials studied by Costello, Williams, and Ginn, as well as other vessels excavated during the past thirty-five years. He stated that he “could tell that the potters of the missions were very skilled and understood the ceramic process,” including the technique known as “throwing from the mound” (figs. 41, 42).

Several common forms found in colonial Mexico and other corners of New Spain have been replicated. Wheel-made forms include brimmed plates and bowls (platos and soperos; figs. 43, 44); small cups and bowls (escudillas or tazas; figs. 45, 46); large storage jars; comales; and chocolate pots (chocolateros; figs. 47, 48). Large basket-shaped, wheel-made storage vessels (fig. 49) have also been replicated (fig. 50).

The use of a pottery anvil is another fabrication technique that involves a positive mold over which a disk of clay is beaten to take the form of the mold. Sometimes gourds or other fired ceramic forms serve as the molds for this type of fabrication. A wooden paddle or the palm of the hand were used to shape the clay. This is one of the ways pottery is currently made in Mexico and was made by the Kumeyaay people of the San Diego area and across Spanish colonial California (fig. 51).[72] An example by Reyes is illustrated in figure 52. Even unskilled workers can rapidly make shallow bowls using this technique (figs. 53-55). In experiments conducted in conjunction with the project, untrained middle-school and college-aged novices were making these vessels in less than thirty minutes after receiving instructions from our project’s master potter (fig. 56).

The fabrication of replica forms provides researchers and the general public with a clearer picture of the sophistication of California’s colonial potters.[73] From such studies we can begin to bridge the gap to the past and in turn create a more three-dimensional picture of the era to the public.

Firing Technologies

In Alta California, ceramic tableware, bricks, roof tiles, and earthenwares generally fired at temperatures above 1220°F (660°C).[74] By analogy, a campfire can exceed 1300°F (600–850°C). In Mexico, firings in shallowly dug (12–20 in.) open pits can reach temperatures as high as 1550°F (850°C), depending on the nature of the clay, fuel, wind, and so forth.[75]

Experimental firings of ceramic vessels in open pits are providing insights into the efficiency of different fuels and the manner of stacking the pit, as well as the success rate of this firing technique (fig. 57). Often the presence of “firing clouds” or incomplete oxidation is cited as evidence of open-pit firing (fig. 58), but this is not always accurate since reduction can be found in both kiln- and pit-firing conditions. The experiments have demonstrated that plain or bisque ceramics could have been adequately fired using the open-pit technique, but a more sophisticated kiln would have been required for making glazed ceramics.

While open-pit firing is suitable for the manufacture of earthenwares, the use of a kiln is vital to the production of lead-glazed ceramics. The INAA data provided evidence of the production of kiln-fired, lead-glazed ceramics at sites the length of California, among them San Francisco, Santa Clara, San Juan Capistrano, Carmel, San Francisco, and Santa Barbara.[76] Fabrication of glazed ceramics is a two-step process. First a green vessel must be fired to “bisque.” Then a lead-based glazing compound is applied and the ceramics are fired a second time. This second firing melts the lead, fusing it to the bisque. To glaze pottery, a kiln is needed as it can achieve the temperature necessary to melt the glaze. By using a kiln one can also control surface color by moderating the atmosphere between oxidation and reduction through the addition of fuel and restricting the flue to regulate heat and gasses (fig. 59).

Specialized kiln furniture was needed to allow for efficient stacking without the danger of vessels fusing together. The atmosphere and firing effects can be regulated with the use of saggers. Saggers are large ceramic chambers within the kiln into which the glazed vessels are placed to protect them from licking flames, smoke, and ash (fig. 60).

Plates fired within a sagger were separated using nails (clavos) inserted through the sagger’s walls during firing (fig. 61). A similar method employs fired triangular clay rods to support the vessels (fig. 62). Glazed plates could also be fired using a cock spur or caballito (figs. 63, 64).[77] This three-armed, bisque-fired trivet is placed directly on the glazed surface of a vessel to separate it from other vessels in the kiln’s chamber (fig. 65). After the kiln is unloaded, the caballito is popped free from the glazed surface, leaving three small marks in the glaze (fig. 66).

Reconstructing a Spanish Pottery Kiln

On July 27, 1796, California governor Diego de Borica wrote to Felipe de Goycoechea, the commandant of the Santa Barbara Presidio, and said that Goycoechea would need 10,000 bricks to make a pottery kiln. Once the potter in Monterey was finished with his work, he would be transferred to Santa Barbara to start producing the bricks. Shortly thereafter, Goycoechea reported a kiln was under construction.[78] While no unequivocable pottery kiln has thus far been archaeologically identified, indirect evidence of a kiln from Mission San Francisco comes from an excavated fragment of a cock spur.[79] A late-nineteenth-century photograph (figs. 67, 68) taken at Mission Santa Barbara shows a roofed two-chamber updraft kiln. As late as the 1940s two-chamber kilns were built and used in California to make pottery (fig. 69).

To better understand the firing technology of the era, in the spring of 2006 we joined with the Santa Barbara Trust for Historic Preservation at El Presidio de Santa Barbara State Historic Park and built a kiln. The resulting fully operational, full-size two-chamber updraft demonstration kiln was a valuable addition to the park’s public interpretation of life on the Spanish colonial frontier. Furthermore, the replica ceramics it yields can be used for interpretation while the public firing of a “historic” kiln provides a venue for conducting experiments in the efficiency of different fuels (fig. 70).

Previously, the only replicated mission-era pottery shop and kiln in California was at La Purísima Concepción (fig. 71). The reconstruction program at that mission was carried out between 1934 and 1942 with manpower supplied through the Civilian Conservation Corps as part of the National Park Service’s National State Park Emergency Conservation Work Program. After the war, funding became available to continue the program of reconstruction under Superintendent Arthur Sill into the 1950s. The Pottery Shop and Kiln (1951–1954) represents the first post–World War II state park reconstruction at La Purísima Mission State Historic Park. Park staff conducted the excavations, made the adobe blocks, and reconstructed the shop building, pottery wheel, and kiln (fig. 72).

In 1951 the Pottery Shop was the subject of a study by California state park archaeologists; later it was reconstructed by the California Department of Parks and Recreation on the original foundations. Archaeological evidence, including unfired clay pipe, tile, and two large millstones for the crushing of the clay, suggested this was a tile shop. Later it was “interpreted to the public” as a pottery shop.

The La Purísima Mission Advisory Committee recommended that a nonfunctioning kiln be added to the reconstructed Pottery Shop to better explain the firing process to visitors. At the same meeting, the committee recommended the addition of a pottery wheel. According to the minutes of March 17, 1951, the subcommittee for structures recommended “construction of a kiln for the firing of pottery at the north end of the building, if after archaeological reconnaissance, foundations for such a kiln are not found elsewhere in the vicinity. The kiln is to be square, similar to or duplicating that shown in Mrs. Webb’s photograph of the kiln at Santa Barbara Mission.”[80] The plan for the kiln was drawn three years later, in 1954, but does not indicate whether the kiln was intended for pottery or tile.

With the aid of a historic photograph of a pottery kiln at Mission Santa Barbara, and the non-functional replica kiln at Mission La Purísima Concepción as a template, Michael Imwalle of the Santa Barbara Trust for Historic Preservation and Ruben Reyes constructed a kiln (fig. 73). Test-firing of this full-size replica kiln in April 2006 (fig. 74) demonstrated that in seven hours a temperature of more than 1700°F could be achieved. Temperatures during an experimental glaze firing in April 2007 were carefully monitored over a period of twenty-four hours (fig. 75). Results from this and other experimental firings of ceramic vessels in this kiln were compared with those conducted in open pits and are providing insights into the efficiency of different fuels, the manner of stacking the kiln, and the success rates of different firing techniques (figs. 76, 77).

The experimental firings conducted during this project have provided valuable data for the interpretation of ceramics recovered from Spanish colonial archaeological sites throughout New Spain. The construction of the two-chamber updraft kiln has also enabled the Santa Barbara Trust for Historic Preservation to interpret accurately the entire ceramic production process for visitors to El Presidio de Santa Barbara. Student interns process raw clay from onsite excavations (fig. 78). This processed clay is then used to demonstrate the making of wheel-thrown and hand-modeled pottery. Once made, the vessels are fired in the kiln or in pit-firing demonstrations (figs. 79, 80). As a result of this work, both researchers and the public have gained a greater appreciation of the skilled artisans who lived in Alta California two hundred years ago.

Maiolica, Mayólica, Majolica: Tin-glazed Ceramics in Alta California

Tin-glazed ceramics are found from San Diego to north of San Francisco. Beginning with the work of Arnold Pilling on Spanish colonial ceramics in 1952 and continuing a generation later through the efforts of other California archaeologists, the information on colonial economics and acculturation derived from the fragments of these colorfully decorated ceramics (fig. 81) continues to fascinate scholars.[81] Unfortunately, in the realm of public interpretation there has been little interest in providing accurate replicas in restored settings. To rectify this shortcoming, our projects and Santa Barbara Trust for Historic Preservation utilized the skills of the project’s master potter to fabricate these ceramics and make this information available for the interpretation of historic sites.