Teabowl, attributed to John Bartlam, Cain Hoy, South Carolina, 1765–1772. Soft-paste porcelain with transfer-printed decoration. H. 1 5/8", D. 2 7/8". (Private collection; photos, Gavin Ashworth.)

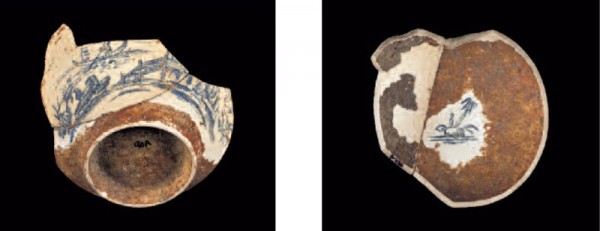

Teabowl fragment, recovered from the John Bartlam site, Cain Hoy, South Carolina, 1765–1769. Soft-paste porcelain. (South Carolina Institute of Archaeology and Anthropology; photos, Gavin Ashworth.)

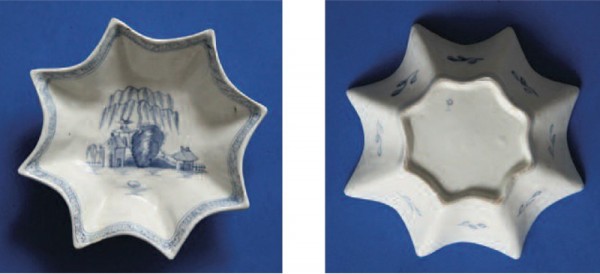

Dish, possibly the American China Manufactory, Philadelphia, Pennsylvania, 1770–1772. Soft-paste porcelain. D. 5 7/16". (Private collection; photo, Nicholas Panes.) This dish is designated “Sample STR.”

Saucer, possibly the American China Manufactory, Philadelphia, Pennsylvania, 1770–1772. Soft-paste porcelain. D. 4 15/16". (Private collection; photo, Nicholas Panes.) This saucer is designated “Sample DB1.”

Sauceboats, probably the American China Manufactory, Philadelphia, Pennsylvania, 1770–1772. Soft-paste porcelain. H. 3 3/8", W. 3", L. 6 1/2". (Independence National Historic Park, Philadelphia; photo, Jed Levin.) These two reconstructed sauceboats (samples 2028A, 2028B) were recovered from Independence National Historic Park in Philadelphia. Based on their composition and mineralogy, they have been attributed to the Bonnin and Morris factory.

Three sauceboats of a class sometimes attributed to Isleworth (London) factory, England, 1770–1775. Left to right: (U3) L. 6 1/8"; (U4) L. 3 15/16"; (U5) L. 5 1/2". Mark: crescent on U5; others unmarked. (Private collection; photo, Nicholas Panes.)

Plates and dish of a class sometimes attributed to the Isleworth (London) porcelain factory, England, 1765–1775. Soft-paste porcelain. Left to right: (U6, plate) D. 7 1/4"; (U7, dessert dish) L. 8 15/16"; (U8, plate) D. 8". Mark (on all): mock Chinese characters. (Private collections; photos, Ray Howard [U6] and Nicholas Panes [U7, U8].)

Plates with a different style of decoration from those illustrated in fig. 7; tentatively attributed to the Isleworth (London) porcelain factory, England, 1765–1775. Soft-paste porcelain. Left to right: (U9, fluted plate) D. 7 1/8"; (U10, lobed plate) D. 8 1/8"; (U11, basket) D. 8 3/4". Marks: none. (Private collections; photos, Ray Howard [U9, U11] and Nicholas Panes [U10].)

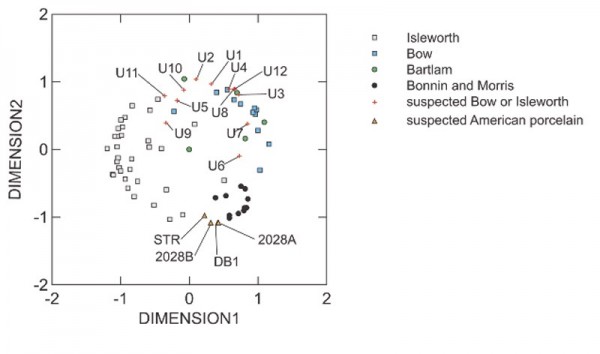

MDS plot for paste compositions of Bartlam, Bonnin and Morris, Bow, and Isleworth porcelain, plotted against data for four suspected American porcelain objects (two intact and two excavated), and twelve intact porcelain objects thought to be either Bow or Isleworth.

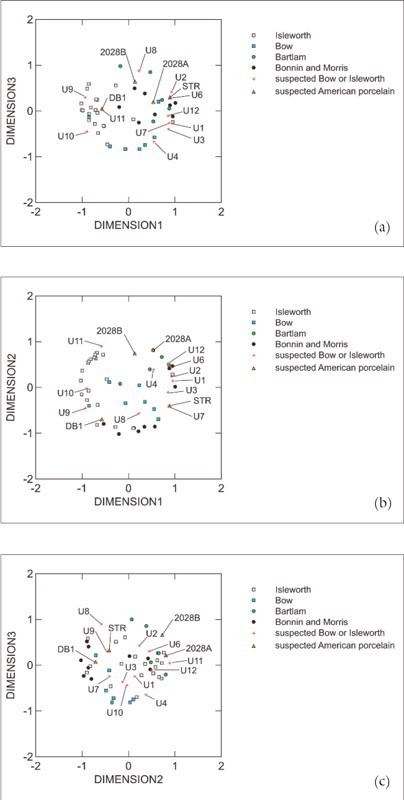

MDS plots for glaze compositions. (a) dimensions 1 versus 2; (b) dimensions 2 versus 3; (c) dimensions 1 versus 3.

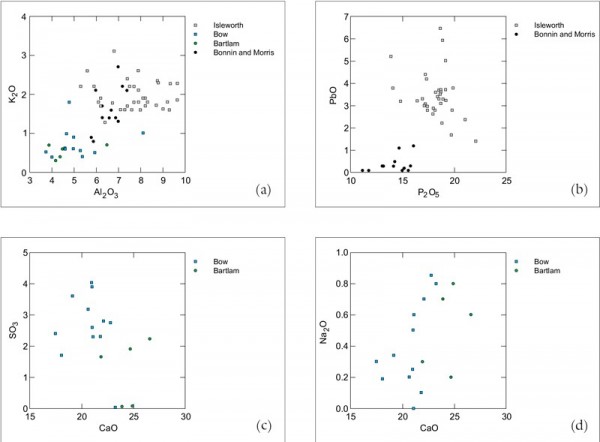

Discrimination diagrams for sulphurous phosphatic porcelain pastes. (a) K2O versus Al2O3; (b) PbO versus P2O5; (c) SO3 versus CaO; (d) Na2O versus CaO.

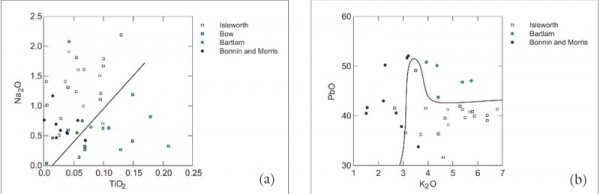

Discrimination diagrams for glazes on sulphurous phosphatic porcelains. (a) TiO2 versus Na2O; (b) PbO versus K2O (the line encloses the Isleworth field).

The past few decades have seen a proliferation of analytical (compositional) data for historical ceramics, most notably eighteenth-century American and British porcelains. These data provide an objective means of characterizing these diverse wares and therefore are useful in provenance and authentication studies. Moreover, when coupled with archival information, analytical data can help trace the dispersion of trade secrets to early porcelain manufacturers not only across Great Britain but also to its North American colonies.[1] Information about ceramic paste and glaze ingredients, their proportions, and other technical aspects of the manufacture of porcelain was transferred from factory to factory by workers changing employment or setting up their own potworks. Some of these workers are identified by historical documents.[2] The influence they had on the wares produced by established or new enterprises is confirmed by comparing the type and composition of porcelain made by the new and previous factories where these migrant artisans worked.

Perhaps the most significant recent discovery concerning the dissemination of porcelain technology and the production of new wares centers on the realization that Bonnin and Morris in Philadelphia (ca. 1770–1773) were likely not the first to make porcelain in what is now the United States. Rather, it seems that a Staffordshire immigrant named John Bartlam produced both fine earthenware and phosphatic (bone ash) porcelain in South Carolina starting in the mid-1760s. His enterprise there ended in about 1770. To date, four intact examples of this porcelain—all teabowls with a printed pattern (fig. 1) matching that from the several teabowl fragments (fig. 2) excavated at the site of his potworks—have been discovered.[3] Although obvious porcelain wasters (biscuit examples or fragments showing firing flaws such as body distortion) do not appear to have been discovered at the site, the general consensus presently holds that John Bartlam produced porcelain in what is now the United States several years prior to Bonnin and Morris.

Analyzed porcelain sherds from the Bartlam and the Bonnin and Morris sites have sulphurous phosphatic compositions and lead-rich glazes.[4] The body of some of the Bonnin and Morris fragments contains small amounts of lead, a component not yet detected in analyzed Bartlam pastes.[5] A dated (1773) and marked (“Philadelfia”) openwork porcelain basket attributed to Bonnin and Morris, however, has a silicious–aluminous–calcic (SAC) composition. If it was indeed made by Bonnin and Morris, as seems likely since no other maker of porcelain is known in Philadelphia at that time, this artifact demonstrates that at least two types of porcelain pastes were produced at this factory.[6]

Diverse types of artificial (soft-paste) porcelains were produced in Britain starting in the 1740s (or perhaps earlier), including those with phosphatic and SAC compositions. Of the many porcelain factories that manufactured phosphatic porcelains during the mid-eighteenth century, only two—Isleworth and Bow (both of London)—are known to have included sulphur and/or lead in their ceramic pastes. The presence of either or both of these components in early American porcelains therefore points to the influence that London factories had on their counterparts across the Atlantic. In the case of Bonnin and Morris, it appears that a William Ball (a former employee at the Bow factory but later manager of the former William Reid works in Liverpool), together with a number of ex-Bow workmen, provided knowledge to Bonnin and Morris at their Philadelphia factory about how to make Bow wares.[7] Just how John Bartlam became familiar with the use of sulphur (probably in the form of gypsum, a common calcium sulphate mineral), however, is not known.

This paper focuses on the composition of eighteenth-century American and British porcelains with variably lead-bearing, sulphurous phosphatic compositions: those made by Bow, Isleworth, Bartlam, and Bonnin and Morris. Published analytical data for sherds of this material, supplemented by the compositions of authenticated and documentary pieces, are compared with the compositions (1) of a dozen intact, blue-and-white decorated objects that have been assigned, on aesthetic and compositional grounds, to either the Bow or Isleworth factory, and (2) two intact dishes and two excavated but reconstructed sauceboats suspected to have originated at the Bonnin and Morris factory.[8] Unlike the first-cited study, which uses binary (X-Y) plots of selected components to distinguish between products of the two London factories in question, in the present contribution we use an exploratory statistical method that collectively appraises all components simultaneously. New discrimination diagrams have then been constructed using these analytical data.

Sample Description

The information compiled here comprises published data for both paste and glaze compositions. The former outnumber the latter because at some sites many of the excavated porcelain sherds are biscuit and, in the case of glazed objects, the glaze may in rare instances flake away from its ceramic substrate during sample preparation (polishing of glass-mounted ceramic fragments).[9] To avoid clutter on the statistical plots, data reported for glazes only and not for the associated pastes (e.g., the averaged Bow glaze compositions reported by Ross Ramsay and coworkers) were avoided but are included in discrimination diagrams described below.[10]

The two intact porcelain objects suspected to be American in origin are (1) a star-shaped dish (fig. 3) marked on its base with a P, the symbol commonly used by Bonnin and Morris, and (2) an unmarked saucer (fig. 4) painted in underglaze blue with a house, a willow tree growing from a rock, and curling reeds. The compositions for both are reported in Table 1.

Two sauceboats (fig. 5) excavated from Independence National Historic Park in Philadelphia have been assigned to the Bonnin and Morris factory on the basis of their (1) similarity to a Bonnin and Morris sauceboat in the Brooklyn Museum, and (2) composition and the presence in their bodies of heavy minerals that match those in clay deposits at White Clay Creek, a tributary of the Delaware River, known to have been exploited by Bonnin and Morris.[11]

Twelve intact, sulphurous phosphatic objects variously attributed to Bow and Isleworth were included in the sample. These include a saucer and two baskets that have been illustrated elsewhere.[12] Illustrated in this article are three sauceboats (fig. 6), three plates (fig. 7), and three dishes (fig. 8).

Statistical Methods

Paste and glaze analyses were subjected to exploratory statistical analysis (multidimensional scaling [MDS]) to identify compositional relationships between the different samples.[13] MDS resembles principal component analysis except that the results are usually easier to interpret because variance is summarized in fewer dimensions. The MDS calculations were performed using SYSTAT software. This software does not distinguish one sample (or chemical component) from another and does not seek correlations supporting preconceived models for relationships between samples or chemical components.

The clustering of data points on MDS diagrams identifies which elements are geochemically linked in the analyzed samples and, likewise, which samples are related. In the present study, only sample compositions are examined, since the behavior of particular components is largely irrelevant to distinguishing the products of different porcelain factories.

In essence, MDS diagrams can be thought of as “maps” showing “distances” between samples or chemical constituents. In three dimensions, MDS data tend to plot as a spheroidal cloud of points that can be viewed in three, mutually perpendicular planes (dimensions 1 versus 2, 3 versus 2, and 3 versus 1). Generally, only the first of these two-dimensional plots is required to interpret the analytical data, but if a relatively imperfect circle is defined by the plotted data (i.e., some points plot in its interior), then additional planes should be consulted.

Samples (or chemical constituents) that are similar, or that behave similarly, plot close together on MDS diagrams. Points on opposing sides represent samples (or chemical constituents) that are dissimilar or behave differently. These diagrams can be used to interpret compositional similarities and dissimilarities in a variety of media, including earthenware, glass, rocks, and fluids such as wine and even maple syrup.[14] In the present application of the method, the analytical data are restricted to major and minor elements (Si, Ti, Al, Fe, Mn, Mg, Ca, Na, K, S, and Pb, expressed as oxides). Trace element data (and isotopes) for these porcelain wares have not yet been determined (or, at least, reported in the literature).

The same paste and glaze data used to generate MDS plots provided a basis for generating new discrimination diagrams using F-statistics as a guide for identifying diagnostic components that best distinguish the products of the different porcelain factories considered here.[15]

Results

PASTE COMPOSITIONS An MDS plot for sulphurous phosphatic porcelain paste compositions is shown in figure 9. The plotted compositions of samples excavated from the Bonnin and Morris site cluster in a tight field in the lower right of this diagram. In contrast, four of the five Bartlam samples plot in a broader field in the upper right, with one sample (B10) plotting in the interior of the diagram. The main cluster of Bow samples overlaps the field defined by most of the analyzed Bartlam sherds. Significantly, all four suspected American porcelain samples cluster at the bottom, between the Bonnin and Morris and the Isleworth fields; two (DB1 and 2028A) plot atop one another on this diagram.

The plotted compositions of most of the analyzed fragments from the Isleworth factory define an arc on the left side of figure 9, although five samples plot in the interior of the diagram, and one plots closer to the lower right, near the field for the Bonnin and Morris samples. The compositions of the Bow fragments plot as an arc on the right to upper-right part of figure 9. The average composition of Bow pastes circa 1747–1754, with a relatively aluminous composition, however, plots in the upper left of this diagram.[16]

The compositions of the twelve analyzed intact objects suspected to be either Bow or Isleworth porcelain plot as an arc along the top of figure 9, extending toward the right from one end of the Isleworth field, and overlapping the fields for Bow and Bartlam porcelain.[17] Their distribution is generally consistent with inferences made about their origin based on aesthetic criteria and the three ceramic-paste discrimination diagrams shown in Table 2 (Test 1, Test 2, and Test 3) proposed by Panes and coworkers.[18] Six samples (U1, U3, U4, U7, U8, U12) cluster with the Bow samples on figure 9, and another (U6) plots close to the Bow field. Three other specimens (U5, U9, U11) plot close to the Isleworth field. A blue-and-white basket with the Pinecone pattern (U2) and thought to be Bow, and a powder-blue plate (U10) considered to be Isleworth, plot approximately midway between the Bow and Isleworth fields.

GLAZE COMPOSITIONS Nick Panes and his colleagues noted that published analyses of Isleworth glazes tended to be enriched in both Na2O (soda) and Al2O3 (alumina) compared with their Bow counterparts.[19] Three of the intact powder-blue objects described in that paper (U9, U10, and U11 in Table 2) plot in or near the Isleworth field, corroborating their attribution to that factory based on paste compositions. In contrast, neither of the suspected Bow powder-blue plates (U6, U8) plots in the Bow field on Panes et al.’s glaze diagram, since they are relatively enriched in alumina.[20] The glazes on the other intact objects plot in or near the Bow field on their soda versus alumina diagram (see Table 2), supporting their attribution to the Bow factory based on paste compositions. It therefore seems that these two glaze components have some potential in distinguishing the phosphatic wares produced by these two factories.

What if all analyzed glaze components for sulphurous phosphatic wares were appraised simultaneously? An MDS plot for glaze compositions is shown in figure 10a. Apart from two outlying samples (U4, U8), the compositions of the glazes on the analyzed intact objects plot in two fields. As in Panes et al.’s soda versus alumina plot, the glazes on powder-blue samples U9, U10, and U11 cluster in or near the field for Isleworth glazes on the left side of figure 10a. Six glazes plot on the opposing side of this diagram, but not with Bow glazes, most of which form an elongate field across the middle of figure 10a. Instead, they are associated with Bartlam glazes, some of the Bonnin and Morris glazes, and one Isleworth glaze. The glaze on a lobed, powder-blue plate (U8) plots near the Bow and the Bonnin and Morris fields, whereas the glaze on a blue-and-white sauceboat (U4) plots near a Bartlam glaze in the interior of figure 10b.

Most Bonnin and Morris glazes plot on the bottom of figure 10a, overlapping the Isleworth field, whereas others plot on the upper right. The two excavated sauceboats have glazes that plot close to one another on the top right of the diagram, close to several Bartlam glazes. The glaze on the suspected American saucer (DB1) plots at the left end of the lower Bonnin and Morris glaze field. The glaze on the P-marked star-shaped dish (STR) plots in the gap between the two Bonnin and Morris fields, coincident with the position of the glaze on a powder-blue dessert dish (U7).

The clustering of most Bow glazes in the interior of figure 10a suggests that their relation to other glazes should be considered in other dimensions. Consequently, all glaze data are plotted on two other MDS diagrams: dimensions 2 versus 3 (fig. 10b) and 1 versus 3 (fig. 10c). In contrast to figure 10a, glaze data on the dimensions 1 versus 3 plot (fig. 10c) define a clear circle, with relatively few points in its interior. Apart from one outlying glaze on the upper right, Bow glazes form a well-defined arc on the lower part of the diagram that overlaps with the main Isleworth field to the left. Several of the intact objects suspected to be Bow (see Table 2) plot as extensions of this field (U1, U3, U7, U12); only one (U4) plots within it. The three powder-blue specimens thought to be Isleworth (U9, U10, U11 in Table 2) are associated with the Isleworth field. Bartlam and Bonnin and Morris glazes overlap on the right, and their collective field encloses three of the four suspected American dishes (2028A, 2028B, STR). The fourth (DB1) is coincident with a suspected Isleworth sample (U11).

The glaze data are distributed as a poorly defined circle on the dimensions 2 versus 3 plot (see fig. 10b), suggesting that it is of relatively little use in distinguishing most samples. The Bow field is on the lower left and contains only one of the suspected Bow objects (U7). Most Isleworth glazes plot on the upper-right and middle-right part of the diagram. Of the three powder-blue dishes with strong Isleworth paste attributes (see fig. 7), only the glaze on U11 is associated with the Isleworth field on this diagram.

Some New Discrimination Diagrams for Sulphurous Phosphatic Porcelains

Statistical evaluation of published sulphurous phosphatic paste compositions shows that several elements can be used to distinguish these wares. This can be accomplished in two ways. Components can be sought which help distinguish the products of (1) all four factories (Bonnin and Morris, Bartlam, Bow, and Isleworth) from each other, and (2) one factory from the others. In the first instance, there invariably is some overlap of points representing the compositions of one type of porcelain (paste or glaze) with those of another. Consequently, it is more effective to use a series of diagrams designed to distinguish the products of two or three of the four factories considered here, rather than all at once. Bartlam, Bonnin and Morris, Bow, and Isleworth pastes are best distinguished by Si Al, P, and the alkalis (or subsets thereof). Their glazes can be distinguished by Ti, Na, K, and Pb.

Examples of discrimination diagrams based on these various components are shown in figures 11a–d (pastes) and figures 12a and b (glazes). Figure 11a compares the potash and alumina contents of Bartlam, Bonnin and Morris, Bow, and Isleworth porcelain pastes. Most of the analyzed Bow samples have lower concentrations of these components than Isleworth, so this plot clearly distinguishes these two factories. It also distinguishes between products of the two American factories, but there is nearly complete overlap of Bonnin and Morris compositions with the Isleworth field (even though there is no known association between these two factories) and of Bartlam with the Bow field (even though Bow is linked to Bonnin and Morris). So, another plot must be used to distinguish between Bartlam and Bow, and between Bonnin and Morris and Isleworth. Isleworth pastes have higher lead contents than those of Bonnin and Morris, so a lead oxide versus phosphate plot (fig. 11b) diagram separates these two wares. Similarly, higher lime but lower sulphate contents tend to distinguish Bartlam from Bow porcelain, so the CaO versus SO3 diagram (fig. 11c) helps separate these two wares. A lime versus soda plot (fig. 11d) can also be used for this purpose.

As with the discrimination diagrams based on paste compositions, those constructed for glazes tend to distinguish two or three factories from one another, but not all of the four considered here. For example, a titania versus soda plot distinguishes most of the analyzed Bow from Isleworth glazes, but both American factories overlap the latter’s field (fig. 12a). However, a lead oxide versus potash plot (fig. 12b) can be used to distinguish most Bartlam, Bonnin and Morris, and Isleworth glazes.

Discussion

The use of compositional data to identify or authenticate early American and British porcelain objects is limited by the small number of samples and the limited number of components that have been determined, and reported, for these wares. Despite the limited amount of data for these wares, attempts to determine the origin of both intact and archaeological specimens on compositional grounds have met with some notable successes. Perhaps best-known among these was the recognition of the first intact specimens of Bovey Tracey porcelain—first a fuddling cup[21] and later a sauceboat.[22] Composition-based attributions are best attempted in conjunction with aesthetic criteria but in and of themselves are inherently objective and avoid the subjectivity of connoisseurship. There nonetheless remains the strong possibility that variations in the pastes and glazes produced by a given porcelain factory are as yet unrepresented in the analytical database currently available for early American and British wares. For this reason, simply plotting the composition of the paste and/or glaze of an unidentified specimen on a discrimination diagram, or diagrams, might mislead the researcher. The result of this approach, to be reliable, should be consistent with what is known about the character of the wares of the factory suspected to have produced the sample. In other words, there should be no “loose strings.”

An advantage of the statistical approach (MDS) advocated here is that the software evaluates all data simultaneously, rather than piecemeal. This reveals relationships between samples, or the constituents (chemical components) making up these samples, that would elude the researcher casually perusing the dataset.

The MDS plots reported here highlight both similarities and dissimilarities between the sulphurous phosphatic porcelains produced at different American and British factories. They supplement more traditional, binary (X-Y) plots comparing, for example, the Al2O3 and P2O5 concentrations in phosphatic porcelain pastes. Nick Panes and coworkers proposed additional binary plots to help distinguish among twelve intact objects suspected to be either Isleworth or Bow.[23] These diagrams, supplemented by aesthetic criteria, pointed to a Bow origin for most of these samples, and MDS of the paste data tend to support this interpretation (see fig. 9). It is encouraging that, with one exception, the paste compositions of analyzed sherds from the Bow and Isleworth factory sites plot on distinct parts (opposing sides) of figure 9. This largely reflects the relatively high lead content of Isleworth porcelain.

The paste compositions of the four suspected American porcelain objects plot in a tight cluster between the Bonnin and Morris and Isleworth fields (see fig. 9). Although it is known that former Bow employees found work at the Bonnin and Morris factory, to our knowledge there is no known connection between Isleworth and either American factory. Moreover, the excavated sauceboats (2028A, 2028B) contain some of the same heavy minerals that occur in a known clay source (White Clay Creek, a tributary of the Delaware River) used by Bonnin and Morris. The clustering of all four of these objects near Bonnin and Morris supports but does not prove a Philadelphia origin for these artifacts. The compositions of their glazes are broadly consistent with this interpretation. Bonnin and Morris glazes plot as a divided arc on the upper right/bottom of one of the MDS glaze diagrams (see fig. 10a), and as an irregular cluster on another (see fig. 10b). In the case of the former, glaze compositions of the suspected American artifacts plot as extensions of the Bonnin and Morris fields; in the case of the latter, three of the four plot in the Bonnin and Morris field, with the intact saucer (DB1) being associated instead with the Isleworth field.

Apart from three of the powder-blue dishes thought on the basis of their paste compositions to be Isleworth, the glazes of the intact Bow/Isleworth artifacts show less clear affiliation with the fields of glazes for these two types of porcelain. As noted elsewhere,[24] the use of glaze compositions in provenance/authentication studies is potentially problematic. Glazes can be compositionally zoned, can contain irregular concentrations of refractory ingredients (notably tin oxide, a whitener and opacifier), and, in some instances (such as at unusually high glost kiln temperatures) can behave as a chemically open system, exchanging or taking up components (e.g., alumina) from the ceramic substrate,[25] and losing lead at high temperatures to the kiln atmosphere.[26] At extreme temperatures (approaching those at which true porcelains are fired), all the lead from the glaze can eventually be driven off.

Although peak temperatures in the glost kiln were intended to be much lower than those used to fire artificial porcelain biscuit (prior to glazing), the common observation that glazed wares (found in wasters at factory sites) suffered body distortion demonstrates that glost kiln conditions could be difficult to control. Indeed, it may well be that variations in the compositions of glazes (e.g., their lead content) noted on wares made during particular periods of a factory’s production history may largely be a result of this effect rather than substantial differences in their recipes, although this inference could be disputed given the discovery of detailed factory records to the contrary.

It is not always the case that the degree, if any, of zoning in porcelain glazes is noted or even sought by analysts, and those using portable XRF to test glaze compositions are, by necessity, confined to analyzing glaze surfaces. The same is true for variations in the distribution of refractory particles, although this is of limited concern in the present instance because of the lack of tin oxide particles in most of the analyzed glazes (except, for example, the glaze on the star-shaped dish illustrated in fig. 3; see Table 1). The potential open-system behavior of glazes during kiln firing is of special concern, because a given starting composition of glaze could systematically change its composition with temperature and/or soaking interval. With these caveats in mind, it is nonetheless noteworthy that the glaze data presented by Ross Ramsay and coworkers[27] suggest minor but apparently systematic variations in the compositions of Bow glazes over time (such as an increase in K2O), and the soda versus alumina plot comparing Bow and Isleworth glazes presented by Panes and coworkers shows good field separation.[28] These studies therefore point to the potential use of glazes in provenance studies of artificial porcelains, and indeed, the lead content of glazes are diagnostic of some phosphatic porcelains (e.g., analyzed Nantgarw glazes contain only ~15% PbO).[29] The data presented here suggest that, in the case of Bartlam, Bow, Bonnin and Morris, and Isleworth, titania and the alkalis can be diagnostic of the glazes used at these four factories (see figs. 12a, b).

Only major and minor elements numbering about a dozen are presently available in the literature for historical Anglo-American wares. In contrast, trace element packages offered by commercial labs equipped with a high-precision, mass spectrometer–based apparatus (e.g., laser ablation microprobe—ICP-MS) typically include an additional forty or more components that can be determined at parts-per-million concentrations. Consequently, the analysis of American and British porcelain pastes and glazes for trace elements (and isotopes) could revolutionize not only our understanding of how these wares were made (especially with respect to the sources of their raw materials) but also our ability to distinguish them. Such work has been undertaken on ancient Chinese high-fired ceramics for more than a decade and could serve as a template for these types of investigations.[30]

Conclusions

Statistical analysis of compositional data for sulphurous phosphatic, eighteenth-century American and British porcelains supplements attempts to distinguish the products of different factories using individual pairs of components (or combinations thereof) identified by simply perusing the analytical data. Multidimensional scaling of published data for twelve intact porcelain objects suspected to have been made at either the Bow or the Isleworth factory corroborates their attribution using simple binary plots, but tend to support a Bonnin and Morris origin for two intact dishes for which this attribution initially seems premature.

Despite potential problems related to zoning, and the progressive lead loss and uptake of some components from the ceramic substrate during kiln firing, glaze compositional data also tend serve to distinguish between the sulphurous phosphatic procelains described here. In contrast to ongoing trace element (and isotopic) analysis of ancient Chinese high-fired wares, the analytical investigation of eighteenth-century American and British porcelains has, to date, been confined to major and minor elements. We therefore anticipate that the successful distinction between the products of some of these porcelains and a better understanding of the character and source of their raw materials can be augmented only when a comprehensive database including these additional components becomes available.

ACKNOWLEDGMENTS

We thank Independence National Historic Park in Philadelphia for providing the image of the sauceboats shown in figure 5. Analytical work was supported by a Saint Mary’s University Faculty of Graduate Studies and Research Grant to J. Victor Owen.

J. Victor Owen and Maurice Hillis, “From London to Liverpool: Evidence for a Limehouse–Reid Porcelain Connection Based on the Analysis of Sherds from the Brownlow Hill (ca. 1755–1767) Factory Site,” Geoarchaeology 18, no. 8 (2003): 851–82 [DOI 10.1002/gea.10094]. Nicholas Panes, “Mr Ball the English Potter and the American China Manufactory,” English Ceramic Circle Transactions 20, no. 3 (2009): 633–45.

Dr. Richard Pococke’s widely cited mid-eighteenth-century correspondence describes some of the wares produced at the Lund’s Bristol porcelain factory, whose assets were acquired by the proprietors of the Worcester factory. The names of those associated with the latter enterprise who had previous experience in this industry elsewhere are mentioned in R. Burt, “Profits, Politics and Philanthropy: The Origins of Worcester Porcelain, 1740–1751,” The International Ceramics Fair & Seminar: 2006 ([London]: [International Ceramics Fair], 2006), pp. 22–27.

Roland Arkell, “The First American Porcelain—in Britain,” Antiques Trade Gazette (February 4, 2013), available online at http://www.antiquestradegazette.com/news/2013/feb/04/the-first-american-porcelain-in-britain/

As defined by J. Victor Owen, “A New Classification Scheme for Eighteenth-Century American and British Soft-Paste Porcelains,” in Ceramics in America, edited by Robert Hunter (Hanover, N.H.: University Press of New England for the Chipstone Foundation, 2007), pp. 121–40.

J. Victor Owen, “Geochemical and Mineralogical Distinctions between Bonnin and Morris (Philadelphia, 1770–1772) Porcelain and Some Contemporary British Phosphatic Wares,” Geoarchaeology 16 (2001): 785–802 [DOI 10.002/gea.1020]; J. Victor Owen, “Geochemistry of High-fired Bartlam Ceramics,” in Ceramics in America, edited by Robert Hunter (Hanover, N.H.: University Press of New England for the Chipstone Foundation, 2007), pp. 209–18.

J. Victor Owen and Robert Hunter, “Too Little, Too Late: The Geochemistry of a 1773 Philadelphia Openwork Porcelain Basket,” Journal of Archaeological Sciences 36 (2009): 333–42.

See Owen and Hillis, “London to Liverpool: Evidence for a Limehouse”; Panes, “Mr Ball the English Potter.”

For those assigned to either the Bow or Isleworth factory, see Nicholas Panes, Ray Howard, and J. Victor Owen, “Attribution Enhanced—‘Isleworth Porcelain’ Re-examined,” English Ceramic Circle Transactions 24 (2013): 89–116. For the intact dishes, see Nicholas Panes and J. Victor Owen, “Attribution Enhanced: Possible American 18th-Century Porcelain Finds in England,” English Ceramic Circle Transactions 23 (2012): 11–30. For the reconstructed sauceboats, see J. V. Owen, A. Meek, and W. Hoffman, “Geochemistry of Sauceboats Excavated from Independence National Historical Park (Philadelphia): Evidence for a Bonnin and Morris (c. 1770–73) Provenance and Implications for the Development of Nascent American Porcelain Wares,” Journal of Archaeological Science 38 (2011): 2340–51.

Sources of data are Owen, “Geochemical and Mineralogical Distinctions”; Owen, “Geochemistry of High-fired Bartlam Ceramics”; Panes, Howard, and Owen, “Attribution Enhanced—‘Isleworth Porcelain’”; W.R.H. Ramsay and E. G. Ramsay, “A Classification of Bow Porcelain from First Patent to Closure: c. 1743–1774,” in Proceedings of the Royal Society of Victoria 119, no. 1 (2007): 1–68; J. Victor Owen and T. E. Day, “18th-Century Phosphatic Porcelain: Bow & Lowestoft. Further Confirmation of Their Compositional Distinction,” English Ceramic Circle Transactions 16, no. 3 (1998): 342–44; Owen, Meek, and Hoffman, “Geochemistry of Sauceboats Excavated from Independence National Historical Park”; I. Freestone, L. Joyner, and R. Howard, “The Composition of Porcelain from the Isleworth Manufactory,” English Ceramic Circle Transactions 18, no. 2 (2003): 284–93; and J. Victor Owen, unpublished data.

W.R.H. Ramsay, K. Sutton, and E. G. Ramsay, “Bow Porcelain: Glaze Compositions Associated with the Phosphatic Wares ~1742–1774,” Proceedings of the Royal Society of Victoria 123, no. 2 (2011): 161–71.

Owen, Meek, and Hoffman, “Geochemistry of Sauceboats.”

Panes, Howard, and Owen, “Attribution Enhanced—‘Isleworth Porcelain.’”

Ingwer Borg and Patrick J. F. Groenen, Modern Multidimensional Scaling: Theory and Applications (New York: Springer, 1997); and Leland Wilkinson, M. Hill, J. P. Welna, and G. K. Birkenbeuel, SYSTAT for Windows, Version 5: Statistics (Evanston, Ill.: SYSTAT, 1992).

See J. Victor Owen and John D. Greenough, “Mineralogical and Geochemical Characterization of Eighteenth-Century Moravian Pottery from North Carolina,” in Ceramics in America, edited by Robert Hunter (Hanover, N.H.: University Press of New England for the Chipstone Foundation, 2010), pp. 168–87; and J. Victor Owen, Dorota Forfa, and John D. Greenough, “Geochemical and Mineralogical Constraints on the Provenance of L’sitkuk Bear River Pottery from the Annapolis Basin, Nova Scotia,” Canadian Journal of Archaeology 38, no. 1 (2014): 76–105. J. Victor Owen and John D. Greenough, “Influence of Potsdam Sandstone on the Trace Element Signatures of Some 19th-Century American and Canadian Glass: Redwood, Redford, Mallorytown, and Como-Hudson,” Geoarchaeology 23, no. 5 (2008): 587–607 [DOI 10.1002/gea.20232]. See John D. Greenough and J. Victor Owen, “A Petrochemical Study of Basaltic Layering at Henley Harbour, Labrador, Using Multidimensional Scaling,” Atlantic Geology 38, nos. 2–3 (2002): 161–75. See John D. Greenough, Leanne M. Mallory-Greenough, and Brian J. Fryer, “Geology and Wine 9: Regional Trace Element Fingerprinting of Canadian Wines,” Geoscience Canada 32, no. 3 (2005): 129–37; and John D. Greenough, Brian J. Fryer, and Leanne Mallory-Greenough, “Trace Element Geochemistry of Nova Scotia (Canada) Maple Syrup,” Canadian Journal of Earth Sciences 47, no. 8 (2010): 1093–110 [DOI 10.1139/E10-055].

An F statistic is a value obtained when a regression analysis or analysis of variance test is run to determine whether the mean between two populations of data is significantly different.

Panes, Howard, and Owen, “Attribution Enhanced—‘Isleworth Porcelain,’” Table 1.

See ibid.

Ibid.

Ibid.

See the Na2O versus Al2O3 plot in ibid., fig. 17.

M. White, “A Bovey Tracey Fuddling Cup,” English Ceramic Circle Transactions 19, no. 3 (2007): 501–7.

Nicholas Panes and J. Victor Owen, “Attribution Enhanced—A Bovey Tracey Porcelain Sauceboat,” English Ceramic Circle Transactions 21 (2010): 125–34.

Panes, Howard, and Owen, “Attribution Enhanced—‘Isleworth Porcelain.’”

J. Victor Owen, “What Analytical Data Can (and Cannot) Tell Us about 18th-Century Fine Ceramics,” English Ceramic Circle Transactions 22 (2011): 215–30.

This effect is commonly seen in natural petrological systems, for example, at the interface between layers of metamorphic rocks of different composition, across which components can migrate on a millimeter-to-decimeter scale. See J. Victor Owen, “Syn-metamorphic Element Transfer across Lithological Boundaries in the Port-aux-Basques Gneiss Complex, Newfoundland,” Lithos 29, nos. 3–4 (1993): 217–33.

See Robert L. Hallse and Ralph L. Cook, “Volatility Studies of Lead Silicate Melts,” Journal of the American Ceramic Society 41, no. 9 (1958): 331–36 [DOI 10.1111/j.1151-2916.1958 .tb12927.x]; and Daniel Rhodes, Clay and Glazes for the Potter, 3rd ed. (Iola, Wisc.: Krause Publications, 2000).

Ramsay, Sutton, and Ramsay, “Bow Porcelain.”

Panes, Howard, and Owen, “Attribution Enhanced—‘Isleworth Porcelain,’” fig. 17.

See J. Victor Owen and Michelle L. Morrison, “Sagged Nantgarw Porcelain (ca. 1813–1820): Casualty of Overfiring or a Fertile Paste?,” Geoarchaeology 14, no. 4 (1999): 313–32 [DOI: 10.1002/(SICI)1520-6548(199904)14:4<313::AID-GEA1>3.0.CO;2-H], and J. Victor Owen, John O. Wilstead, Rheinallt W. Williams, and Terence E. Day, “A Tale of Two Cities: Compositional Characteristics of Some Nantgarw and Swansea Porcelains and Their Implications for Kiln Wastage,” Journal of Archaeological Science 25, no. 4 (1998): 359–75.

See Baoping Li, Jianxin Zhao, Kenneth D. Collerson, and Alan Greig, “Application of ICP-MS Trace Element Analysis in Study of Ancient Chinese Ceramics,” Chinese Science Bulletin 48, no. 12 (2003): 1219–24 [DOI 10.1360/02wb0121]; and Baoping Li, Jianxin Zhao, Alan Greig, Kenneth D. Collerson, Zhen-Xi Zhuo, and Yue-Xin Feng, “Potential of Sr Isotopic Analysis in Ceramic Provenance Studies: Characterisation of Chinese Stonewares,” Nuclear Instruments and Methods in Physics Research B: Beam Interactions with Materials & Atoms 240 (2005): 726–32 [DOI 10.1016/j.nimb.2005.06.003].