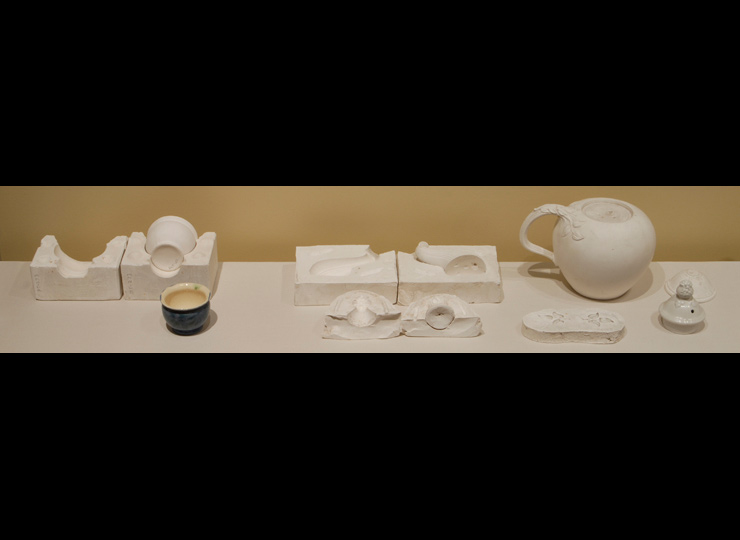

Thorley formed most of his wares using a method called slip-casting. This process involves pouring liquid clay called "slip" into a plaster-of-Paris negative mold. The absorbent plaster sucks the water out of the slip leaving a layer of clay on the inside walls of the mold. The excess slip is poured out and the clay vessel is allowed to dry before being removed and fired. Thorley’s studio included the “working” molds, which are the negative molds into which the slip is poured, as well as the “block” or “master” molds, which are the positive shapes used to make the working molds.

Various related molds for spouts and handles from Hall Brilliant Teapot Series.

Lent by Jewel Lynn Delaune

Working mold, bisque-fired, and glazed ointment pot.

Notice that the finished ointment pot, which has been fired twice, is slightly smaller than the once-fired or “bisque” version. Each time a piece of earthenware is fired it shrinks in size between 3% and 5% percent.