View of the exposed remains of the floor of the Charles F. Decker kiln excavated in 2004. The circular updraft kiln has an approximate diameter of fifteen feet from the center to the exterior wall and is bisected by a flue channel. An iron door, used to seal a firebox or draft hole, is visible in the foreground. (Photos, William Hoffman.)

Jar or crock, Charles F. Decker, Washington County, Virginia, ca. 1869–1873. Biscuit stoneware. Scale is in centimeters. This fragment, hand-painted with cobalt, may depict a partial signature or date.

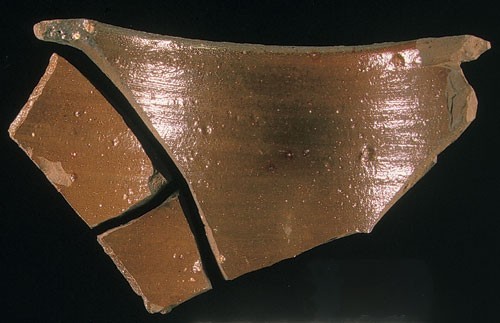

Sherds, Charles F. Decker, Washington County, Virginia, ca. 1869– 1873. Salt-glazed stoneware. Scale is in centimeters. Example of a vessel interior coated with a dull brown, iron-based slip.

The Civil War ravaged the interdependent, kin-based social and economic networks that supported craft communities within the rural South.[1] Particular to the production of ceramics in southwest Virginia, the fragmentation of these local craft communities during Reconstruction fueled an influx of landless immigrant potters, funneled from the northeastern United States through the ridge and valley conduit of the Great Road, into the rural South. A previous regional study identified the location of numerous potters in Washington County, Virginia.[2] Recent excavations in the county have provided a glimpse into the life of one potter who emerged from this milieu.[3]

Charles F. Decker Sr. is representative of the movement of German immigrants from the Northeast along the Great Road that extended between Pennsylvania and Tennessee. Born in Baden, Germany, in 1832, he immigrated to the United States while in his teens and worked at various shops in Pennsylvania and Delaware. For unknown reasons Decker and his family migrated to the town of Abingdon in Washington County, Virginia, about 1869 or 1870; perhaps he was lured by advantageous economic conditions and readily available resources including clay deposits and salt from the nearby town of Saltville. Decker briefly produced wares in Washington County on land owned by the Mallicote family; then, in 1873, he left Abingdon and established the Keystone Pottery in the Nolichucky River valley near Johnson City, Tennessee. This large-scale production establishment is where his more famous and collectible wares were produced. The Keystone Pottery ceased production in 1910, and Charles F. Decker died in 1914.

Excavations have shed light on Decker’s brief sojourn at his smaller and lesser-known shop in Washington County. The investigation revealed that his wares were fired in a circular updraft kiln (fig. 1)—in contrast to the more typical southern groundhog kiln—a preference that likely stemmed from his German upbringing and his apprenticeship in the northeastern United States. Excavations within a waster pile adjacent to the remains of the kiln led to the recovery of wares representing a broad spectrum of production possibilities, including individualized cobalt decorated vessels (fig. 2), storage crocks, jugs, canning jars, tobacco pipes, and drainage pipe. The majority of the vessels within the waster pile were undecorated or minimally decorated with simple, hand-painted, cobalt floral motifs. Simple and utilitarian squared or rounded everted rim shapes dominated the assemblage, although complex beaded-rim types, manufactured with the use of a template, were also present. Most vessels were coated with a dull-brown iron slip—probably a homemade and inexpensive Albany-like slip that gave the wares a uniform appearance (fig. 3).

Decker’s shop in Abingdon fits within a pattern of broad changes related to the responses of local potters to local needs, as well as to the economics of the larger ceramic industry. The presence of drainage pipe, tobacco pipe, and standardized stoneware preserve jars indicates an attempt to maintain a viable role as a local producer of utilitarian wares while competing with the industrial production of such utilitarian goods as Mason’s glass canning jar.[4] In addition, the fully industrialized ceramic centers of Trenton, New Jersey, and East Liverpool, Ohio, likely influenced local demand and shaped the decisions Decker made in terms of the types and styles of wares to produce.

The decline in production of local stoneware in Washington County by the turn of the century is illustrated by the ceramic assemblage of an early-twentieth-century tenant house constructed immediately on top of the kiln remains. The ceramics associated with this later occupation are almost entirely composed of mass-produced, refined white earthenware, thus marking the end of a significant era after the Civil War of locally produced stoneware.

William Hoffman, Archaeologist, The Ottery Group, Inc.; willie.hoffman@ otterygroup.com

Paul R. Mullins, “Negotiating Industrial Capitalism: Mechanisms of Change among Agrarian Potters,” in Historical Archaeology and the Study of American Culture, edited by Lu Ann De Cunzo and Bernard L. Herman (Winterthur, Del.: Henry Francis du Pont Winterthur Museum, 1996), p. 162.

Christopher T. Espenshade, Skelly and Loy, Inc., Monroeville, Pennsylvania, “Potters on the Holston: Historic Pottery Production in Washington County, Virginia,” report on file, Virginia Department of Historic Resources, Richmond (2002).

Excavations were conducted during May 2004 by The Ottery Group at the Mallicote-Decker Kiln Site (44wg556) on behalf of the Threatened Sites Program of the Virginia Department of Historic Resources. Thomas Bodor, William Hoffman, Christopher Sperling, and Thomas Rutledge, The Ottery Group, Silver Spring, Maryland, “Archaeological Evaluation of the Mallicote-Decker Kiln Site (44wg556), Abingdon Vicinity, Washington County, Virginia,” report on file, Virginia Department of Historic Resources, Richmond (2004).

Barbara H. Magid, “An Archaeological Perspective on Alexandria’s Pottery Tradition,” Journal of Early Southern Decorative Arts 21 (winter 1995–96): 73.