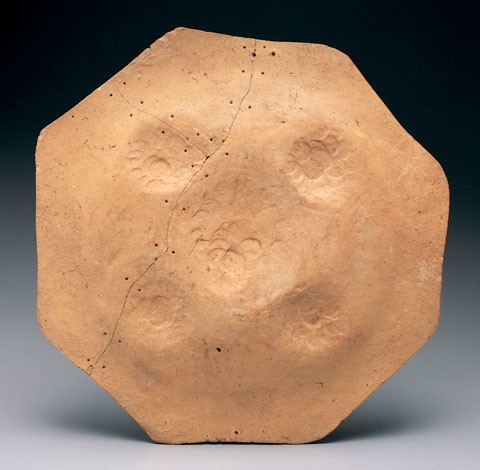

Dish, North Devon, ca. 1670. Slipware. D. 12 1/8". A sgraffito-decorated dish excavated at Jamestown, Virginia. (Collection of Colonial National Park, National Park Service; photo, Gavin Ashworth.) The pattern on this dish is representative of the bold, stylized floral designs found on much of the North Devon sgraffito slipware.

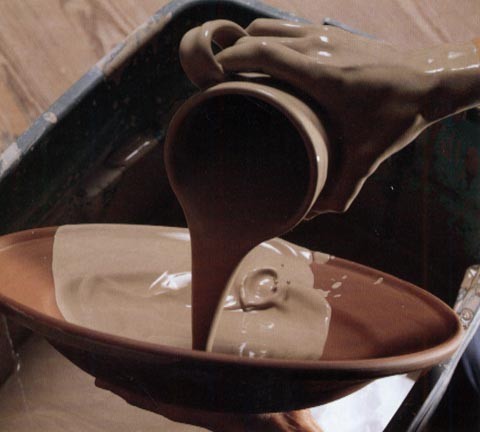

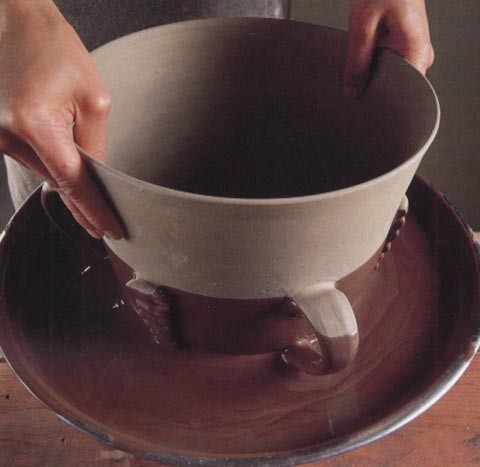

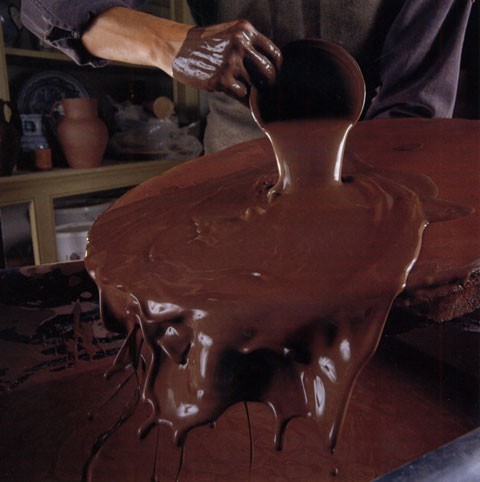

White slip is poured on the upper surface of a wheel-thrown, North Devon–type dish. The dark-bodied charger is at the leather-hard stage. The excess slip is immediately poured off and the charger is set aside to dry. (All demonstration

photography is by Gavin Ashworth.

Coffee pot and lid, Sussex, ca. 1790. Slipware. H. 7". (Courtesy, Chipstone Foundation; photo, Gavin Ashworth.) The design on this coffee pot was scratched or incised into the leather-hard, red clay body. A white slip was applied over the design and scraped or cut away, leaving the filled lines.

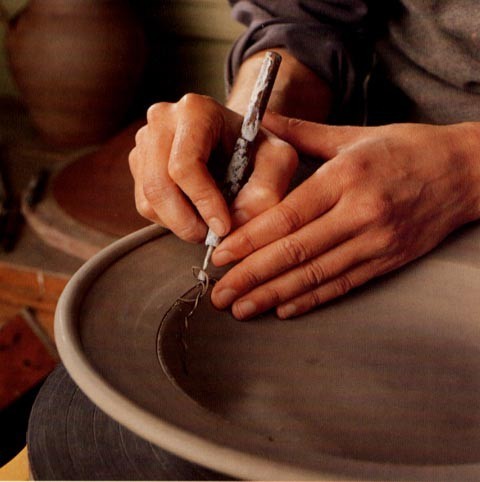

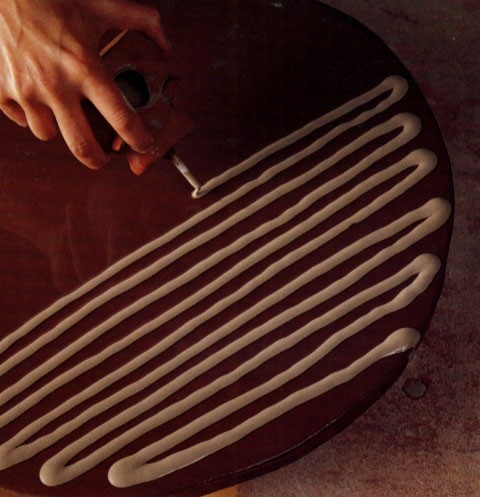

Once the slip covering has set up to a leather-hard stage, the sgraffito design is begun. The initial framing of the design is done on the wheel with the layout of concentric circles. The stylus is simply held in a fixed position while the wheel rotates, cutting the lines.

After laying out the initial design, the pattern is incised freehand. The lines are scratched quickly, in a very fluid, gestural movement. Mistakes at this stage are usually not easily corrected. Typical North Devon patterns are floral and geometric designs, although stylized birds and other natural motifs are often seen as well.

A looped wire tool is used to remove larger areas of slip within the outlined areas.

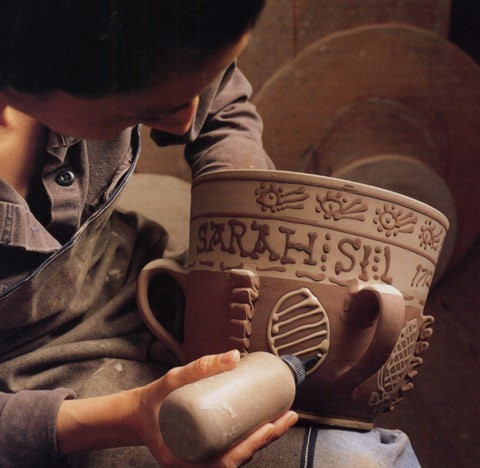

Tyg, Wrotham, 1631. Slipware. H. 7 1/4". (Courtesy, Colonial Williamsburg Foundation.) The ornamentation on this tyg consists of coils and pads of white clay augmented with slip-trailed highlights. The white clay slip is applied directly to a red clay body.

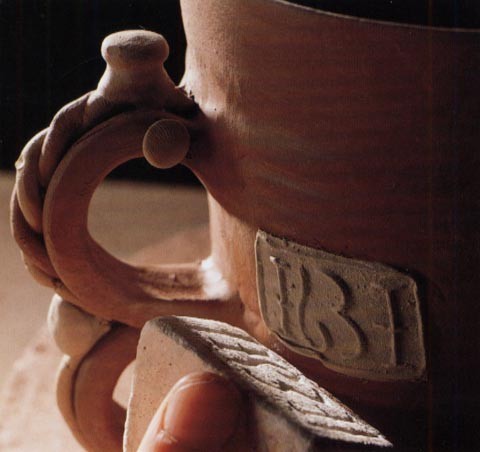

A pad of clay is applied to the leather-hard body and subsequently embossed with a plaster stamp. The clay pad needs to be soft and pliable at this stage in order to get a good impression. The red clay body of the cup, however, has to be fairly firm so that the pressure of the stamping does not deform the shape. Period examples often show evidence of the indentations of the potters’ fingers behind the embossed pads on the inside of the vessel.

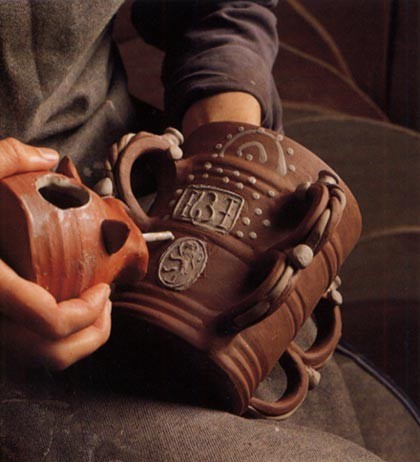

After the clays pads are applied and embossed, white slip is trailed to complete the decoration. Note that strips of white clay have been applied to the handles.

Cup, Staffordshire, 1712. Slipware. H. 7 5/8". (Courtesy, Colonial Williamsburg Foundation.)

The wheel-thrown cup made of white or buff clay has been assembled with handles and the pleated clay flourishes. The bottom half of the cup is dipped in a black slip, the excess is allowed to drip away, and the bottom is wiped clean. The top half of the cup is then dipped into a white slip and both slips are allowed to firm up before decoration is applied.

The initial layout of the design is started by applying concentric lines to the pot on the wheel. Black slip is used on the white ground slip where as a white slip is applied over the black ground slip. The decoration is done freehand and the vessel has to be turned carefully to avoid marring any of the previously applied trailing. A modern slip squeeze bottle is being used.

A final embellishment known as “jeweling” is applied. Small dots of white slip are used on top of slip lettering from the previously trailed black slip decoration.

Dish, Staffordshire, probably Burslem, 1700–1725. Slipware. D. 13 1/4". (Courtesy, Chipstone Foundation; photo, Gavin Ashworth.) Slipware press-molded dish with pomegranates and fleurs de lis. A master mold had to be carved to create the relief decoration on these types of dishes.

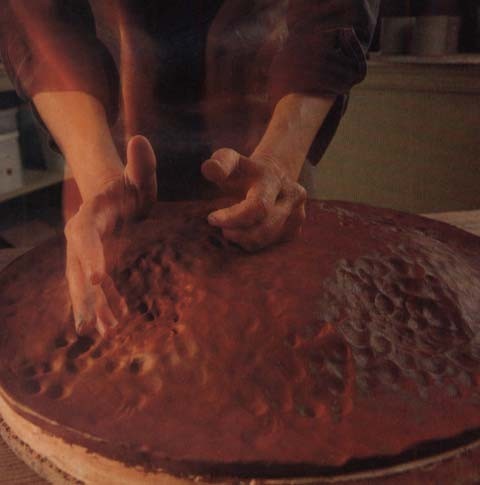

A circular clay slab is draped over a carved plaster mold. The clay is moist and very plastic at this stage. Period molds appear to have been made of fired clay.

The depth of the carved relief requires that the slab be firmly pressed into the recesses. Slapping or pummeling the slab with a closed fist accomplishes this. After the dish firms up, it is removed and the edges are trimmed.

The reverse of the original pomegranate dish illustrated in fig. 14, showing the indentation caused by pressing the clay slab into the deep recesses of the mold. Note that the back of this dish has been neither slipped nor glazed.

After the slab dries to a leather-hard state, a white ground slip is poured over the interior surface only. Subsequent highlighting of the designs is done with red and black slips using a trailer.

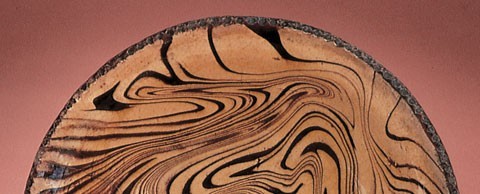

Dish, Staffordshire or Midlands, 1720–1750. Slipware. D. 13 3/4". (Courtesy, Colonial Williamsburg Foundation.) This press-molded, marbled-slip dish is among the most competent examples of this decorating technique.

Creating a marbled-slip dish begins with a black ground slip poured over a flat, circular, red earthen clay slab, previously prepared and supported by a wooden bat. Slabs were prepared by rolling out the clay to an equal thickness.

Parallel lines of white slip are immediately trailed onto the wet ground slip. The consistency and moisture content of the slips must allow both to flow easily without running. The width of the lines is dictated by the distance of the tip of the slip tube from the surface of the ground slip: the further from the surface, the wider the line.

The prepared slab immediately before joggling. Note how the white slip lines have overlapped the edge of the slab.

Detail of the marbled dish illustrated in fig. 19. This detail shows the white slip lines, which have overlapped the edge in the making.

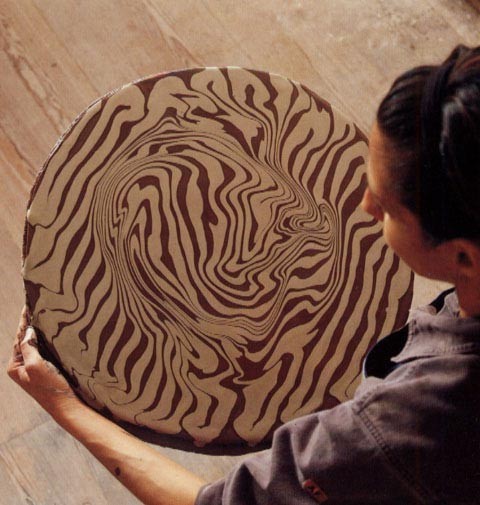

The beginning of the marbleization process. The slab, resting on the bat, has been rotated or “joggled” to start the flow of the slips.

The marbleized slab in the process of joggling. Because both slips tend to dry fairly quickly, the potter must have good control over the process and the decision to stop is an important aesthetic, as well as practical, concern. Elapsed time for joggling is usually no more than a minute or two.

The marbleization process is complete. Note that the decoration is still on a flat slab. Before the vessel is formed, the slips must be allowed to set up to prevent marring of the marbleized surface, yet the slab and the newly slipped surface must remain pliable. If the slab becomes too dry, it will crack. If the slips are still too wet, they will stick to the surface of the mold.

After sufficient drying, the slab is draped over a hump mold and pressed into place to form the dish. These molds were typically made of fired clay, although a plaster one is being shown here. The dish is now allowed to dry further, to a leather-hard stage. The irregular edge is trimmed with a knife to form a completely circular form and the rim is then crimped or coggled. This molding process helps flatten the slips. After glazing, the surface is smooth.

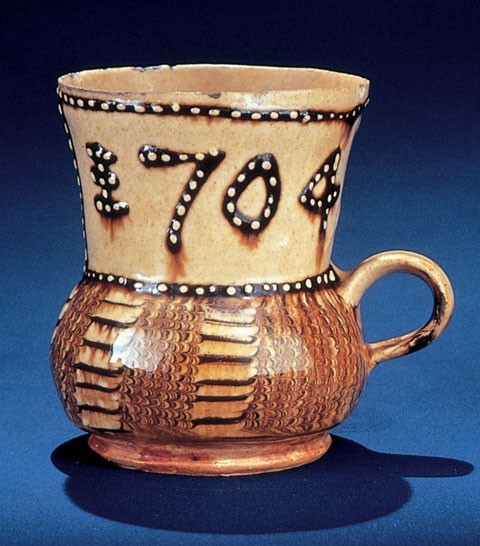

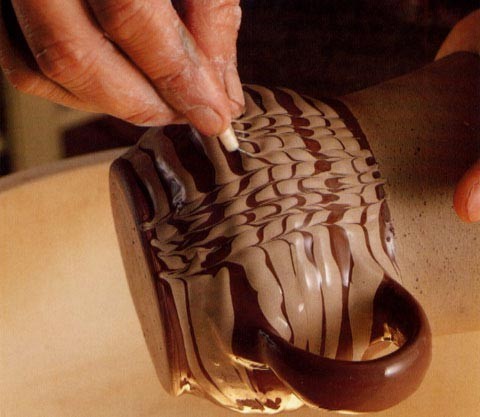

Cup, Staffordshire, dated 1704. Slipware. H. 4 1/2". (Courtesy, Colonial Williamsburg Foundation.) An early example of a fine-grained, combed slipware cup. Trailing and jeweling have been used on the upper portion of the cup.

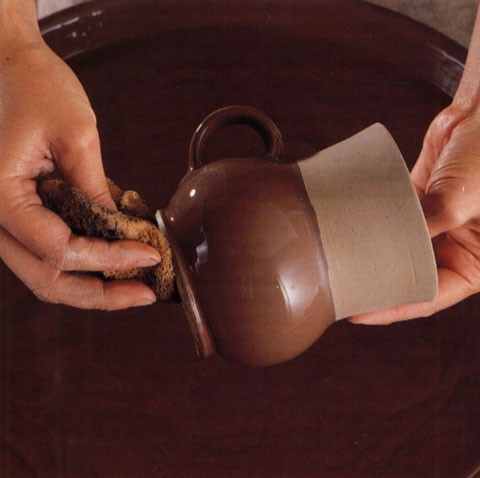

The lower half of a thrown mug of buff-colored earthenware is dipped into a black slip. The black slip is immediately sponged off the bottom of the mug.

Using a multinozzled slip trailer, white parallel lines are applied over the wet, black slip. Experimentation has suggested that the mug was supported horizontally, perhaps on a lathe or similar device, to facilitate the application of the slip.

A comb, fashioned with bristles or filament, is drawn through the wet slips to create the feathered effect. The bristles drag the overlying white slip through underlying black slip.

English slipware sherds from a late-seventeenth-/early-eighteenth-century archaeological context; Hampton, Virginia. Examples of North Devon sgraffito and Staffordshire combed and marbled wares. (City of Hampton Collection; photo, Robert Hunter.)

Seventeenth-and eighteenth-century slipware has long been considered one of the hallmarks of British ceramic history. Consequently, interest in these wares runs deep. Collectors admire the bold graphic designs and rich earthy colors and they favor the dates, names, or initials that are found on many surviving pieces. American archaeologists unearth English slipwares in prodigious quantities, providing dating information on seventeenth- and eighteenth-century historical sites. Art potters have found inspiration in traditional English slipwares, notably reflected in the twentieth-century work of Bernard Leach and his students (see opposite page). In the latter half of the twentieth century, the reproduction of English slipwares for the history-oriented market became a full-time occupation for many American and English potters.[1]

The collector’s literature recounting the history of slipware extends for nearly a century and a half. Art historians have characterized slipware’s aesthetic qualities relying upon terms such as “rustic,” “folksy,” “primitive,” “crude,” “delightful,” and “naïve.” Ceramic historians have continually described the technological processes involved with English slipware manufacturing, starting with Dr. Robert Plot’s History of the Staffordshire Potteries (1686). Archaeologists, on the other hand, generally have not concerned themselves with the technical or aesthetic aspects of slipware beyond understanding the chronological history of types. Slipware is usually viewed as a staple product of the English potters (particularly the Staffordshire industry), a mainstay of domestic and utilitarian pottery for the masses, and a basis for understanding trade networks that extended over half the globe. The slipware tradition continues today in the works of contemporary potters around the world, involving both time-honored methods and new, highly sophisticated materials and applications.[2]

In light of these varied interests, our article provides a brief overview of English slipware technology focusing on the dynamics of the slip process and the techniques used to create decoration. The authors will demonstrate that although slipware is often considered “rustic” or “folksy,” it is the inherent nature of the materials that dictates the aesthetic character of the ware, not the predisposition of the potter. We only touch on the general history of English slipwares, since excellent summaries have been prepared in recent years, particularly the work of ceramic historian Leslie Grigsby.[3] We should note that all English slipwares were coated with a lead glaze before firing. The lead was either applied as powder or in a liquid form. Glazing and firing strategies have been summarized elsewhere.[4]

Our approach most closely follows that of “experimental archaeology,” which relies upon testing and replication to show how an artifact may have been made. By actually “going through the motions” employed by the early English potters we can better appreciate both the manual processes and the material aspects of slipware. Our research, ongoing for nearly ten years, continues to provide new insights into unrecorded methods of slipware manufacture. These insights range from why certain clays were used to the ability to distinguish the aesthetic success of surviving pieces of slipware.[5]

In the process of learning how to make old pots, it became increasingly apparent that the antique specimens contain clues to every aspect of manufacture, from the types of clays used to their arrangement in the kiln. These clues also provide a context for appreciating the larger production concerns of raw materials, division of labor, and the vast trading network that distributed these wares to the Caribbean and North America. Slipware is often considered a localized tradition, or a cottage industry (a term particularly favored in collecting circles). While small, seasonal potteries existed throughout England, supplying the immediate community, these should not be confused with the Staffordshire potteries and other manufacturing centers that arose in an effort to capture the considerable domestic and foreign markets.

To begin at the beginning, “slip” is best defined as a homogenous mixture of clay and water. The simplest of slips is nothing but clay and water. More sophisticated slips can contain colorants, feldspars, flint for hardness, and various fluxes and frits. English slipware potters typically used a clay for the slip that was finer and denser than the clay body to be covered. This clay was either mined and used in a natural form or refined through sieving, removing coarser particles.

As the properties of slip can vary from one extreme to the other, understanding its nature is important. Slip is a liquid that generally has a very short working life. As soon as slip comes into contact with a dryer surface, it begins to stiffen. It is analogous to working molten glass. Unlike glass, though, slip cannot be reheated or moistened to rework it. A mistake made in applying a slip means living with it or wiping it off and starting over.

When using slip, the clay particles tend to fall out of suspension fairly quickly so that the potter needs to stir the solution frequently. In some cases, the potter can be handling a dish with one hand and stirring a vat of slip with the other. In a factory setting, consistency of materials is a key ingredient in the success of the pottery production line. Care has to be taken from batch to batch to ensure that the viscosity of the slips is monitored constantly. Even so, there is a degree of randomness in the process. A potter who starts out decorating a vessel using a full slip trailer will have the consistency of the slip vary from the start of the process to the time the last drop is applied.

In most instances, slip is poured or dropped onto another surface. Rarely is it brushed on since the clay surface is usually damp, which causes the slip to be streaky or uneven. Although brushing can produce very accurate lines, it also necessitates building up several layers to achieve a smooth surface. Pouring slip, however, instantly creates an opaque, even covering—making the best use of the materials and the time of the potter. But pouring is much harder to control and this is an important difference in contrasting the squiggles of the slipware potters with the better-defined brushwork of their counterparts, the delftware painters.

One amusing aspect associated with describing the process of creating slipware is the use of food analogies. Dr. Plot in 1686 described the slip mixture of clay and water as a “Syrup.” Ceramic historian Lewis Solon depicted slip as “clay diluted with water to the consistence of a batter.” Bernard Leach attributed the visual experience of spreading jam and Cornish clotted cream on his bread at tea time to his rediscovery of the combing or feathering technique on slipware. This close association with food preparation suggests that clay and water are very similar to flour and water. Importantly, it is the degree of moisture in the clay body and the density of the slip mixture that are the primary determining factors in the process.[6]

Most English slip decoration prior to 1760 was carried out by hand, the success of which was directly tied to the ability of the potter. Even with the steadiest of hands, creating a perfectly straight line can be diffcult, particularly if the “flow” of the slip is interrupted (a common occurrence) during the process. After 1760, the individual skill necessary to apply slip decoration in a controlled fashion was somewhat negated by the use of the lathe. The fixed movement of the pot in a horizontal motion permitted the application of a uniform band of slip decoration in a straight line.

The early use of slip decoration in England can be traced to medieval times, when the decoration consisted of simple geometric designs painted on jugs and cups. Medieval English tile makers also used slip to add color and pattern to their products. With the importation of late-sixteenth-century European slipwares, English potters tried to create similar products, appropriating the various slip-decorating traditions as their own.

In copying these European traditions, the English potters had to adopt the local clays and these varied considerably from region to region. In general, though, most coarse red and buff earthenware clay deposits that were available to English potters were well suited to throwing and had great strength at relatively low firing temperatures. In contrast, the finer, white ball clays, while plastic, had to be fired to a much higher temperature to maintain body strength.

Although the white ball clays were ineffcient bodies at low firing temperatures, they did adhere well to the coarse earthenware body. Perhaps more importantly, since the coarse redware clays were relatively porous, at least at the firing temperature achieved by the potters, the use of slip created a surface that allowed a much tighter bond for the lead glaze. In other words, although lead glazes were used throughout the earthenware potting traditions in England, they provided a more effective covering on a slip-covered vessel than on an uncoated, coarse earthenware. Thus, the use of slip was more than just decorative: it actually improved the effcacy of the lead glazes on the coarse earthenware bodies.

The use of slip also broadened the available palette of the Staffordshire potters. White clay-coated slipwares offered a lighter-colored product, challenging the white tin glaze used by the delft potters. Although white clay was commonly used, the iron inclusions in the lead glazes of the period gave the white slip a rich golden appearance after the firing. Other combinations of naturally occurring clays, combined with metallic oxides, produced a range of contrasting colors. These oxides included iron (red), ochre (cinnamon), and manganese (black).

In the early seventeenth century, slipware was being produced in Somerset, North Devon, and Essex. The North Devon and Somerset areas produced slipware with sgraffto decoration, while the Essex potters are best known for their elaborate slip-trailed designs. The North Devon sgraffto wares are among the earliest slipwares found in America (fig. 1). Huge quantities were exported through the ports of Barnstaple and Bideford. The North Devon sgraffto technique was adapted from several European traditions and is the first one we discuss.[7]

Sgraffito

Sgraffto decoration is used primarily on vessels that have been thrown on a wheel. A contrasting color slip, usually white, is applied by pouring or dipping, thus coating the darker clay body of a leather-hard form (fig. 2). “Leather hard” is defined as the stage when the plastic clay has become firm enough to handle without the danger of deformation yet retains a fair degree of moisture.

Hollowwares—jugs, cups, mugs—are ordinarily coated on the exposed outer surfaces, while dishes and plates are usually slipped only on the face. The slip is allowed to set up to a point where it retains a degree of moisture similar to the underlying body. Both the body and the covering slip must be comparatively moist to facilitate the ease of carving. If the slip is too wet, the pattern will smear. If too dry, the slip may flake irregularly along the lines or carved sections.

The process of sgraffto (the term is taken from the Italian “to scratch”) begins with scratching through the slip veneer, using a pointed tool or stylus, to expose the underlying, contrasting clay body. Unlike other slip decorating techniques, this scratching is a subtractive process rather than an additive one. Exceptions to this can be found in the Sussex wares of the later eighteenth and early nineteenth centuries, in which the decoration was scratched first into a solid red body and filled or inlaid with a contrasting white slip (fig. 3).

While much of sgraffto decoration is done freehand, certain techniques are used to set up reference or register marks. For circular dishes and plates, the wheel is used to generate concentric lines (fig. 4-6). Hollow forms may also be rotated on a wheel to produce reference lines. Simple compasses can be used to delineate cartouches as often seen on large harvest jugs. Other tools such as roulettes and coggles were used to repeat patterned decoration. Even with the use of such tools, grit or other inconsistencies in a clay body can cause a straight line to run astray of its intended path. Mistakes made during the sgraffto process are hard to correct without altering the pattern.

It should be pointed out that many of the sgraffto examples in museum collections are generally special pieces, prized by the maker and subsequent owners. Shipping records and archaeological evidence attest that the overwhelming majority of these wares were used, broken, and simply thrown away. The potters who decorated these everyday wares were interested in producing as many as possible. Even if the clay stayed moist enough to allow a potter to linger over a pot, the sgraffto technique required fluid, gestural lines to represent successfully the shape of a bird or the leaves of a flower. These lines had to be scratched quickly and skillfully.

Slip Trailing

By the early seventeenth century, slip-trailed earthenwares were produced in areas south and east of London. Several pottery sites are known from Essex, where the slipware products are referred to as “Metropolitan slipwares,” named such because London was the primary market. These Metropolitan wares were decorated with a white slip trailed directly onto a dark clay body. The city of Wrotham in Kent was another production center for early slip-trailed wares. In addition to trailing, the Wrotham wares were distinctly ornamented with pads of white clay that were embossed with a stamp directly onto the pot (fig. 7-9). In the late eighteenth century, slip trailing was used extensively by the Staffordshire potters.

The application of slip lines or dots over a contrasting clay body is the simplest of decorating techniques and one of the most frequently found on English slipwares (fig. 10-13). Conversely, it is one of the techniques most diffcult to control. Unlike sgraffto decoration, slip trailing is an additive process.

The essential tool for slip trailing was the slip cup. Such cups, or trailers, were generally made to accommodate a single color of slip. The trailer itself was a small vessel, most often made of clay, although leather, fabric, or horn may have also been used. The concept of the trailer was simple. A small tube (a reed or quill) was inserted into the trailer, which would be filled through a top hole. The potter could regulate the flow of the slip by covering the top hole, which also served as a vent. In order for the slip to flow freely, its viscosity had to be maintained by frequently shaking the trailer, and by adding water or a thicker slip mixture throughout the process. Slip tubes clogged easily and had to be continually cleared. Multiple tubes were often used to create parallel line decoration. Multichambered slip trailers, containing a variety of colored slips, came into their own with the introduction of the so-called industrial slipware of the late eighteenth century.

The early trailing techniques in which slip is applied directly to a solid clay body are similar to drawing. The slip quill, or tube, can actually touch the clay surface without marring the design or clogging the opening. In contrast, when slip is trailed over another slipped surface, the quill cannot come in contact with that surface without the risk of marring or clogging (fig. 14-18).

Marbling and Combing

These two techniques are closely related in that they rely upon the movement of contrasting colored slips. Marbling is a process whereby two or more colored slips are laid down and manipulated to create a variegated appearance (fig. 19). Gravity and centrifugal force are key elements in inducing the movement or flow of the slips. Combing, on the other hand, uses a tool to move the slips through one another physically in order to create patterns after they are initially laid down.

The English technique of marbling may have had its origins in the early-seventeenth-century marbled slipwares of Northern Italy. The term “joggling” is used to describe the physical act of controlling the movement of the wet slips. This process can require very specific, and somewhat awkward-looking, body and arm movements. The degree of aesthetic success is directly linked to the skill of the potter in controlling the flow of the slips.

The clays used for making the slips must have similar shrinkage and drying rates. The slips then have to be prepared with similar viscosity. Poorly prepared slips can produce an unsatisfactory flow and impede the marbling process. Inadequate preparation appears fairly common, as shown by archaeological examples (excavated in America) that exhibit a wide range of aesthetic competency. It is not surprising that the marbled slipwares that have survived, primarily in museum collections, are unusually well executed examples.

Marbling on dishes begins with a flat clay disk or slab rolled out in a consistent thickness. The slab is carried with a board or bat to support the wet and still-plastic clay. A coating layer of slip is poured over the slab covering the entire exposed surface (fig. 20). Immediately thereafter, a series of contrasting lines is trailed across the entire surface (fig. 21). The tip of the slip tube should not touch the wet base slip and is held above the surface. Evidence from original examples suggests that the lines were laid down in very specific, prescribed patterns—a deduction that runs contrary to the belief that the marbling process used a more random application of slips (fig. 22, 23). Indeed, it is interesting to note the words of Bernard Leach, who suggested turning slip-trailing mistakes into marbled decoration: “When one or more slips have been unsuccessfully [emphasis added] trailed over a wet background...it is sometimes a good plan to try for a marbled effect by violently shaking and twisting the board upon which the clay rests.” Our research suggests that the initial placement of the slip lines was crucial to creating a successful marbled pattern, contrary to Leach’s suggestion.[8]

After the slip lines are systematically applied, the clay slab, still supported by the bat, is then tipped and rotated (fig. 24-26), using gravity to coax the slips to “flow.” This process will create a pattern of swirls. If the slip is too watery, the lines will run and blur. If the slip dries too quickly, the slips will not flow properly. The potter also has two conscious decisions to make: (1) how much time can be expended before the wet slips stop flowing, and (2) how to judge when to stop before the lines of color lose their separation and become muddy.

The now-marbled slab is set aside to allow the slips to dry further. After the slips are no longer tacky or wet to the touch, the entire slab, which is still plastic, is removed from the bat and placed faced down over a mold. The slab is then carefully pressed into shape (fig. 27). In the case of most English flatware, the marbled or combed decoration is created before the form.

Marbleizing on hollow forms takes place, however, after the vessel has been created, usually by throwing (fig. 28). The ground slip is either poured over the vessel or it is dipped into a container of slip (fig. 29). Contrasting colored slip is then trailed on while the vessel is held horizontally and rotated—either by hand or affixed to a lathe. Our research suggests that a multiple-nozzle slip cup (as opposed to a single nozzle) was used to apply the contrasting concentric slip lines on Staffordshire hollowware forms (fig. 30). The vessel is then tilted and rotated to control the gravitational flow of the slip, creating a variegation of the wet slips. Combing can take place after marbleization or as a stand-alone decorative treatment after the initial trailing of slip lines (fig. 31).

The moisture content of the clay body and the slip has to be carefully monitored when producing marbled or combed slipware. If the clay body becomes too wet, the form will slump or actually fall apart. If the clay body is too dry, the slips will not flow properly. Many of these potential difficulties can be observed in the flaws found on antique or archaeological specimens like those shown in figure 32.

Conclusion

We hope this brief overview has offered a slightly different perspective on the relationship between materials and techniques that produced the design elements on English slipwares. Reading about slipware technology from nearly three hundred years of written descriptions provides some understanding of course. And, as our illustrations included here demonstrate, we certainly feel that a picture is worth a thousand words. But the greatest insights always come from actually doing. For those who have not tried the act of slip trailing, it requires an amazing amount of dexterity to achieve the simplest design. If clay and slip are not available, try decorating your pancakes with maple syrup or honey at the next opportunity. You may be reminded to avoid the words “rustic” and “folksy” and substitute “skillful” or “accomplished” when describing English slipware decoration.

Bernard Leach, A Potter’s Book (London: Faber and Faber Ltd., 1945); Irma Starr, Irma Starr Demonstrates The Lost Art of 17th Century English Slipware Pottery (Kansas City, Mo.: self-published, n.d.).

Louis Marc Solon, The Art of the Old English Potter (London: Bemrose & Sons, 1883); Robert Plot, Natural History of Staffordshire (Oxford, 1686); Gudrun Klix, “Commemorating the Millennium,” Ceramics Art and Perception, no. 40 (fall 2000): 33–44. Illustrated in this last article is a Thomas Toft–style slip charger by Lincoln Kirby-Bell titled “Australia 2000 Coat of Arms.”

Leslie B. Grigsby, English Slip-Decorated Earthenware at Williamsburg (Williamsburg, Va.: The Colonial Williamsburg Foundation, 1993), and Leslie B. Grigsby, The Longridge Collection of English Slipware and Delftware, 2 vols. (London: Jonathan Horne Publications, 2000).

David Barker, Slipware (Buckinghamshire, England: Shire Publication, Ltd., 1993).

Robert F. Heizer and John A. Graham, A Field Guide to Field Methods in Archaeology: Approaches to the Anthropology of the Dead (Palo Alto, Ca.: The National Press, 1967), pp. 141–47.

Plot, Natural History of Staffordshire, pp. 123–24. Solon, The Art of the Old English Potter, p. 27. Bernard Leach, Hamada Potter (Tokyo: Kodansha International, 1990), pp. 125–26.

Alison Grant, North Devon Pottery: The Seventeenth Century (Exeter, Eng.: University of Exeter, 1983).

Leach, A Potter’s Book, p. 114.