Two-handled cup, Staffordshire, dated 1766. Slipware. H. 7 3/8". (Courtesy, Colonial Williamsburg Foundation.) White slip was applied to the red-bodied thrown form. The sgraffito decoration was done by hand on a lathe and augmented with freehand carving of the floral decoration and the date.

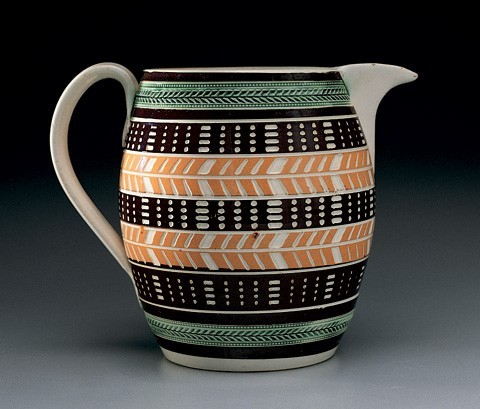

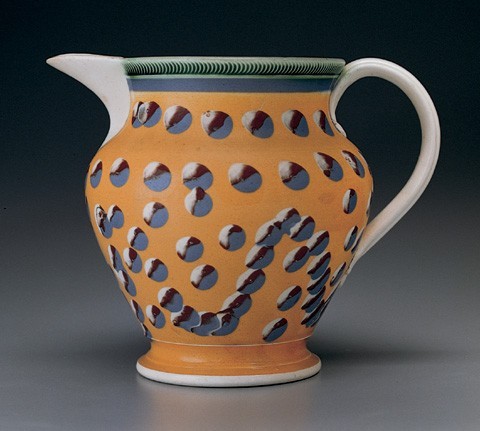

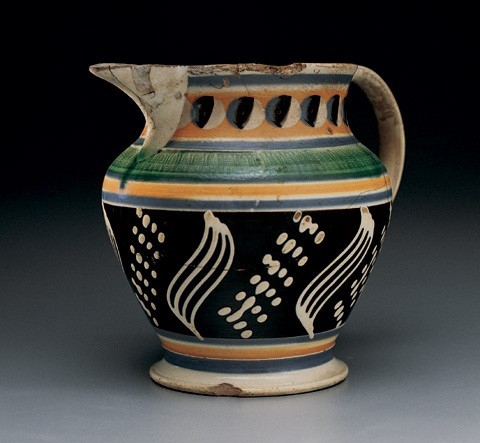

Jug, Great Britain, ca. 1810. Pearlware. H. 6 3/8". (All objects from the Jonathan Rickard Collection unless otherwise noted; photos, Gavin Ashworth.) The jug has toffee-colored and black slip bands and green-glazed rouletted bands, the central area decorated with designs cut through the slip on an engine-turning lathe, using only the edge cam to reveal the body color. The extruded strap handle has press-molded foliate terminals.

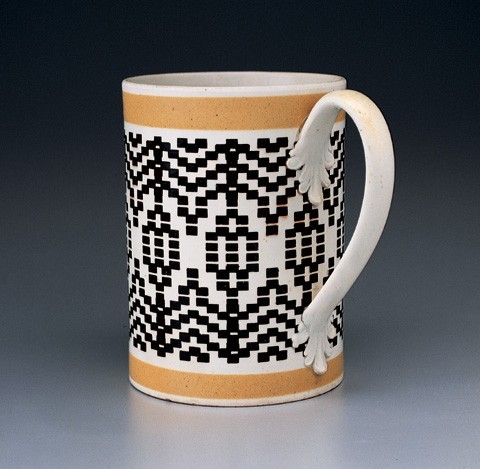

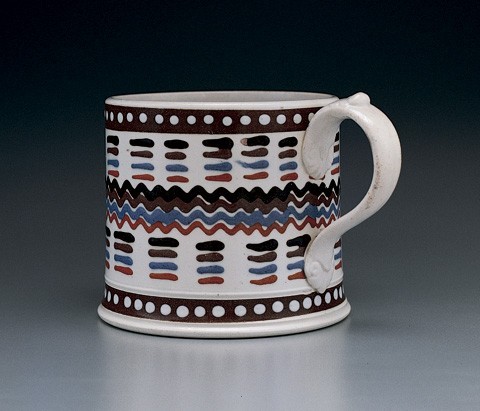

Mug, Great Britain, ca. 1795. Creamware. H. 5 15/16". A quart mug with an engine-turned pattern cut into the pot’s outer body and dipped with black slip, then scraped away to reveal only the slip remaining in the recesses. The extruded strap handle has press-molded foliate terminals.

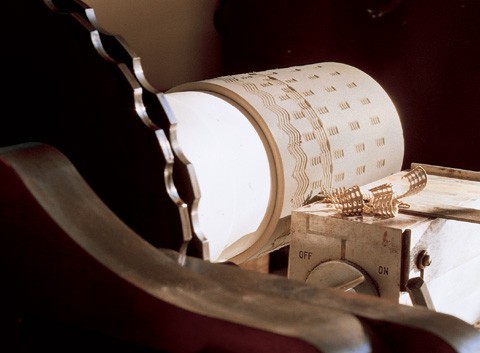

A geometric pattern being cut into a leather-hard mug mounted on Donald Carpentier’s engine-turning lathe.

A detail of a leather-hard mug body as it is being cut. This is one of Carpentier’s earliest attempts at engine turning on the lathe he had built for this purpose. A modified early engine-turning lathe at the Wedgwood Museum in Barlaston, Staffordshire, and an experimental example at the Nicholas Mosse Pottery in Kilkenny, Ireland, are the only other engine-turning lathes in existence for pottery use.

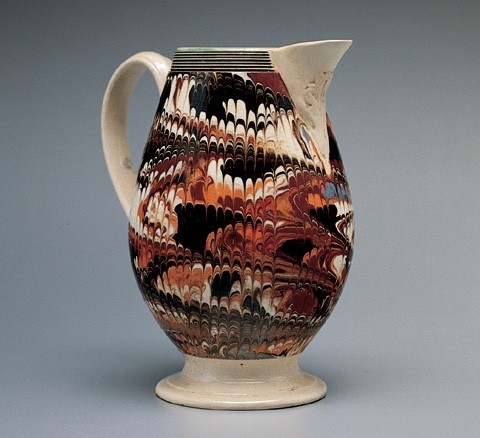

Jug, Great Britain, ca. 1780. Creamware. H. 5 5/8". Baluster-form jug with a press-molded snip (pouring lip) and a simple extruded strap handle. The rim has a green-glazed reeded band above a field of marbled and combed colored slip.

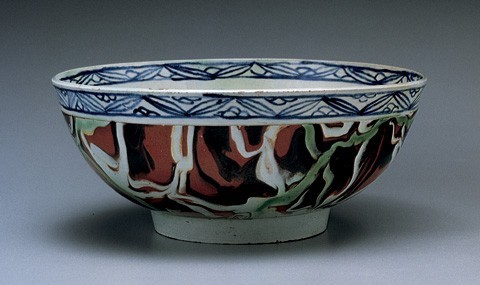

Bowl, Great Britain, ca. 1775. Pearlware. D. 6". Hemispherical bowl in the Chinese shape, the rim painted inside and out in a familiar chinoiserie pattern above a field of marbled slip. This is one of a small group of known examples where areas of the white slip in the marbling have been enhanced with green glaze, much as examples of earlier solid agate possess areas of blue glaze. Sherds from the William Greatbatch factory site in Fenton, Stoke-on-Trent, have the same combination of blue-painted and marbled-slip decoration, but differ considerably in appearance from this example.

Coffee pot and cover, Great Britain, ca. 1785. Pearlware. H. 10 5/8 ". Baluster-form body and cover having vertical reeding created on an engine-turning lathe, along with inlaid agate—tiny bits of different-colored clay adhered to the body with slip and turned smooth. The body also has a band of black slip-filled checkered rouletting, a press-molded spout, and an extruded strap handle with foliate terminals; the cover has a tipped acorn knop.

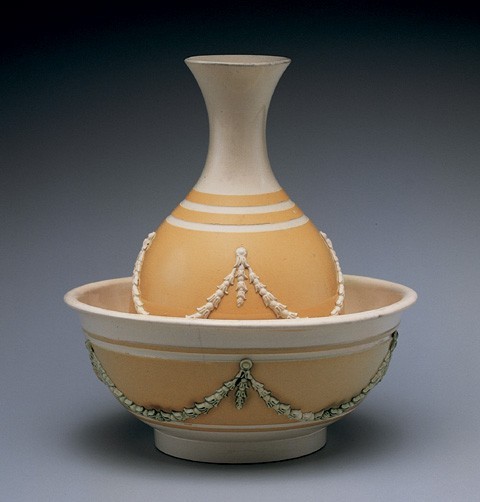

Water bottle and basin, Great Britain, ca. 1775. Creamware. H. 10". This bottle and basin set was dipped in pale yellow slip and cut away in horizontal bands on the lathe. The basin has a rolled rim below which are sprigged bellflower swags touched with green glaze (copper oxide). The bottle has matching bellflower swags without the green glaze.

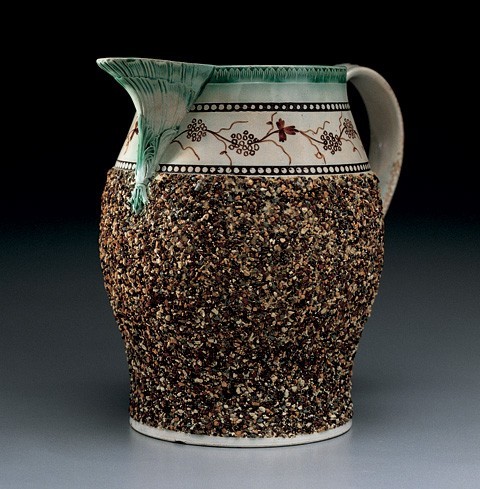

Jug, probably Welsh, ca. 1795. Pearlware. H. 6 7/8". Jug with green-glazed molded rim and press-molded snip, two bands of inlaid rouletted beads, painted vines, and a field of tiny clay fragments beneath the clear lead glaze. Donald Towner referred to this type of decoration as “encrusted.” Nearly matching sherds from the Cambrian Pottery site, Swansea, Wales, are in the Swansea Museum.

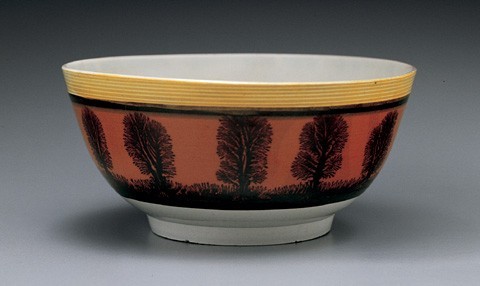

Bowl, Great Britain, 1800–1810. Pearlware. D. 7 1/4". Hemispherical bowl banded with black and rust-colored slips below a reeded band with scarcely encountered yellow glazing. The broader slip field has been embellished with mocha decoration, a black-colored acidic infusion touched to the still-wet slip, where it nearly instantaneously branches out in fine traceries.

Bowl, Great Britain, ca. 1820. Pearlware. D. 6 1/2". London-shape bowl, similar to the bowl illustrated in fig. 11 except that the rouletted rim has the more typical green glaze and the mocha decoration extends over different-colored slip bands.

Period descriptions of turners applying slip decoration often refer to the use of a “blowing bottle” to apply courses of colored thin bands. Here, Carpentier demonstrates the process using a blowing bottle that he made based on period references.

Detail of the application of a single-color string band of slip through the blowing bottle.

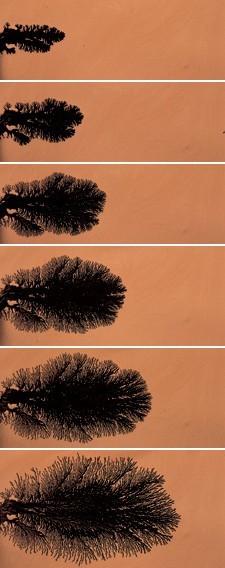

On the mug body banded with the blowing bottle, Carpentier applies mocha decoration. The acidic solution referred to in period documents as “mocha tea” spreads in a random branching pattern on the moist slip.

A second drop of “mocha tea” is added as the mug is rotated slowly on the lathe.

The completed rotation of the mug.

Detail of the mocha process from start to finish. Elapsed time is generally two to three seconds.

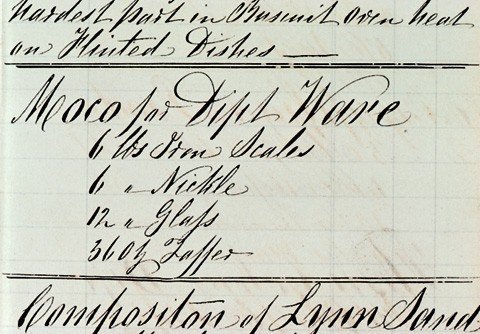

“Moco” formula. Excerpt from a nineteenth-century potter’s recipe book attributed to the Godwin pottery, Staffordshire. (Courtesy, Colonial Williamsburg Foundation.)

Jug, Great Britain, ca. 1835. Pearlware. H. 6 3/4". Jug with tricolored cat’s-eye and cable decoration below a blue slip band and a green-glazed band of rouletting. The extruded strap handle has foliate terminals.

One of Carpentier’s three-chambered slip cups showing the three compartments filled with slip. Period examples were made of tinplate or earthenware.

Detail of the chambers of the slip cup illustrated in fig. 21 showing three colors of slip.

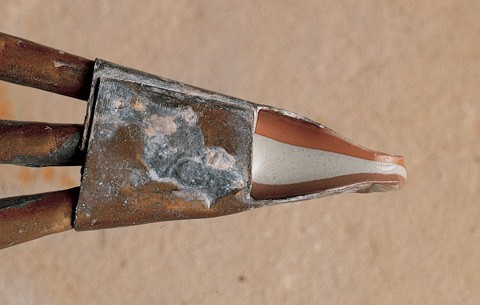

Detail of the tip of the slip cup illustrated in fig. 21.

A close-up view of the three colors of slip as they emerge from the three tubes of the slip cup. They form a single droplet, yet maintain the individual colors that will compose any of the types of decoration for which this tool is used.

The tricolored droplet falling from the slip cup. Note the smaller, secondary droplet falling behind.

Close-up view of a single cat’s-eye, immediately after falling as a tricolored droplet onto a dry surface. When applied to a fairly dry slip field, the moisture in the slip is quickly absorbed by the underlying clay body, fixing the decoration in place. A secondary cat’s-eye is visible in the center of the larger one. This is from the secondary droplet shown in fig. 24. Period cat’s-eye decorations all seem to have this characteristic as well.

Single cat’s-eyes being dripped and starting to overlap.

When cat’s-eyes are quickly overlapped in a continuous line, they form the decoration known to collectors as “earthworm.” The same decoration is referred to in period documents as “cable.” This shows typical cable decoration before the moisture has been absorbed. In practice, conditions varied so that, for example, too much moisture in the body slowed the absorption rate, allowing the top layer of slip to continue moving as the object rotated on the lathe. Likewise, if slip dried too quickly, a quill might become blocked and only two colors would appear. Randomness played a part in the final appearance of these pots.

Mug, Great Britain, ca. 1825. Pearlware. H. 4 3/4". Pint mug with tricolored cat’s-eyes and twigs produced with a three-chambered slip cup. While the blue and black slips appear obvious, white slip is barely present in the designs. This deficiency may be the result of the white slip drying and partially clogging the tube, allowing little to flow onto the pot’s surface. Alternatively, the white slip may have been more fluid and therefore ran out sooner than the other two colors.

By dragging the tips of the three gathered quills in a series of connecting opposing motions, Carpentier replicates the pattern known to collectors as “twig.”

Chamber pot, Staffordshire, 1853–1859. Pearlware. D. 8 3/4". Chamberpot decorated with cat’s-eye and cable in a more subdued palette, indicating a later date of manufacture. The exterior decoration, in fact, matches sherds at the Potteries Museum, Stoke-on-Trent, from the Podmore, Walker & Co. factory site in Tunstall, Stoke-on-Trent.

Mug, Great Britain, ca. 1810. H. 4 3/4". Mug with brown slip bands enclosing yellow-glazed bands usually found on a rouletted surface but seen here on a plain surface. The mug has been further decorated by dipping it into a small pool of multicolored slip. The action of pulling the mug away from the pool of slip caused the slip to pull toward the center of the patch. When the mug was turned upright, the colors flowed toward the bottom. Further embellishment was added in the form of painted fronds on either side of each of the three fans on this rare mug.

In creating the dipped fan pattern, the object to be decorated was dipped partway into a pool of striped or marbled slip.

Pulling the pot out of the slip caused the wet slip to maintain contact in a form of capillary action, resulting in the heaviest concentration of slip appearing in the center of the pattern. When the pot was placed in an upright position, if the slip was wet enough, gravity would cause the wettest portion to stream downward, creating the tail or stem usually seen on these examples.

Mug, probably Scotland, ca. 1840. Pearlware. H. 4 1/8". Pearlware porter mug with several unusual features: the handle is press molded, as opposed to the normal extrusion; the interior is embellished with a painted, press-molded, life-sized frog; the thin brown slip bands near the rim and foot are decorated with white slip dots; and the exterior is trailed with four colors of slip, requiring a four-chambered slip pot. Most multiple, parallel trailed lines of slip found on dipped wares are a single color. To date, the only factory known to be associated with this type of decoration is that of John Thomson at the Annfield Pottery, Glasgow (1812–1884).

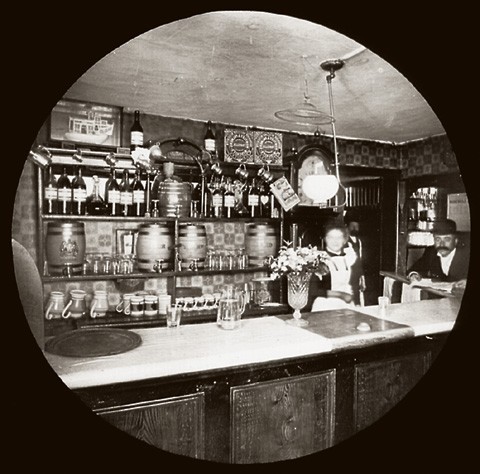

Glass slide of British pub showing mocha tankards, 1890–1910. (Courtesy, Donald Carpentier.)

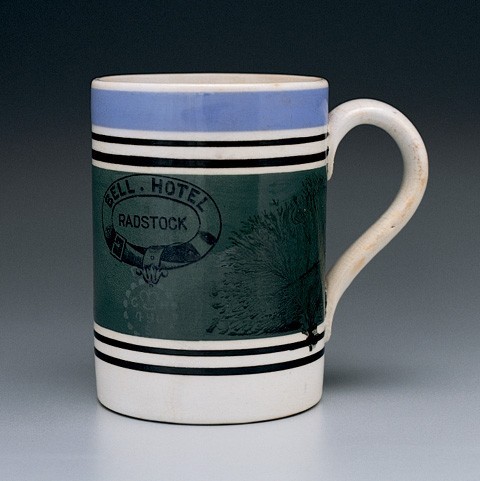

Mug, probably Bristol, ca. 1915. Whiteware. H. 4 7/8". Whiteware pint mug with mocha decoration in an unusual diagnostic color. The broad slip band on mugs of this period is usually in the tan- to olive-colored range. The blue and black bands are standard, though the sequence may vary from maker to maker. In this case, the manufacturer complied with prevailing English law requiring vessels of specific capacity to be so marked and verified by the weights and measures oYcials. The mark is sandblasted through the glaze and reads “gr 490,” followed by either a “5” or an “s.” The “gr” signifies that George V (1910–1936) or George VI (1936–1952) was on the throne; undoubtedly it was the former, inasmuch as most mocha production had stopped by the 1920s. The “490” represents the Weights and Measures District of Bristol City. Above the verification mark is the printed mark of the Bell Hotel, Radstock, whose bar this mug was made for. Radstock is a small town south of the cathedral city of Wells and southeast of Bristol. Radstock was either within the Weights and Measures District of Bristol City or the verification took place at the factory.

Jug, Staffordshire, probably Enoch Wood, ca. 1835. Pearlware. H. 7". Jug with cat’s-eye and trailed-slip decoration and an unusual green-glazed, rouletting pattern. This jug has a history of ownership in Great Barrington, Massachusetts.

This article presents an overview of slip decoration methods that were incorporated into the repertoire of mechanized techniques of the British potters beginning in the second half of the eighteenth century. Building upon earlier technology, slip decoration was employed on a wide range of earthenwares. At the high end of the economic scale, Josiah Wedgwood embellished his costly, neoclassical wares with slips (liquid clay). At the lower end, slip decoration was also used on an entire class of cheap utilitarian earthenwares generally referred to as “mocha” wares today but called “dipt” or “dipped” wares in the period. So prolific was the British manufacture and exportation of these bold, bright, and colorful dipped wares, that they are found on nearly every American domestic archaeological site of the early nineteenth century.

Today, when we look at the broad range of slip decoration on utilitarian pots made for everyday use, we do so with the knowledge of the principles of form from the Bauhaus, the theories on the interaction of color from Josef Albers, and the artistic freedom introduced by the abstract expressionists. We see things that were most likely not seen by the people who created these pots, just as we can look back at the poetry of Robert Frost and find symbolism that may or may not have been intended. For the most part, the mugs, jugs, and bowls illustrated here were meant to function and function well. In later years, the British government went so far as to establish the ideal jug shape for pouring most efficiently. Contrasting with that function was the element of chance that entered into the decoration of most dipped wares.

By the 1760s slip decoration had begun to be used in many ways beyond simple trailing. Lead-glazed red earthenware vessels were dipped in white slip and diced by hand to produce a rough checkerboard appearance. Dicing involved cutting through the slip to reveal the body color and scraping areas free of the slip. At least three known examples of two-handled presentation cups dated between 1759 and 1766 bear this type of decoration.[1] These examples are important because they relate chronologically and add to the small body of evidence leading to the development and use of the engine-turning lathe in the potteries (fig. 1).

Josiah Wedgwood, in letters to his friend and eventual partner, Thomas Bentley, wrote of his fascination with the possibilities offered by the engine-turning lathe. On May 28, 1764, he wrote:

[H]ave sent you a sample of one hobby horse [engine turning] wch., if Miss Oats will make use of she will do me honour. This branch hath cost me a great deal of time & thought & must cost me more & am afraid some of my best friends will hardly escape. I have got an excellent book on the subject in french & latin. Have enclosed one chapter wch. if you can get translated for me it will oblige me much & will thankfully pay any expense attendg to it.[2]

On July 6, 1765, Josiah wrote to Mr. John Wedgwood: “I shall be very proud of sending a box of patterns to the Queen, amongst which I intend sending two setts of Vases, Creamcolour engine turnd, & printed, for which purpose nothing could be more suitable than some copper plates I have by me.”[3] In this letter, it appears that he was sending depictions of items which may or may not have yet been made.

A year later, in a letter apparently sent between October 12, 1767, and October 24, 1767, Wedgwood was further championing the potential of the engine-turning lathe:

Inclosed are Engine Turning, Antiquitys, Plans, &c., & first, of the first, Engine Turning. I think you will meet with nothing very curious ’till you come to part the third, but I suppose you will skim the other part over. I hope you will read with a pen in your hand, & some sheets of blotting paper before you to enter the memoranms. as they occur to you & let me have the Identical sheets on which such memorandms. are made. You will readily conceive which of the Machines may, or may not be applicable to a Potter.[4]

Developed initially for the mechanical trades, the engine-turning lathe allowed potters to decorate vessel surfaces with geometrical precision, using the machine in two different ways. The first involved slip banding on a leather-hard pot using one or more colors. This process was most likely performed on a simple turning lathe. After the slip had set, the vessel was fixed to the engine-turning lathe in a horizontal position. By using a combination of fixed blades and an edge cam, a crown cam, or both, the machine would cut a precise pattern through the thin slip coating to reveal the body color (fig. 2). In the second technique, the leather-hard, undecorated pot was mounted on the engine-turning lathe and a shallow pattern of repeat squares and rectangles was cut into the body. The pot was then removed and dipped into a colored slip or banded with slip on the lathe. After the slip was allowed .to set up, the pot was reaffixed to the lathe and the turner carefully shaved the slip away until the recessed pattern was revealed in the darker, inlaid color (fig. 3-5). These techniques were undoubtedly in use in the 1770s, although no documentary proof has yet been found.

Josiah Wedgwood also figured prominently in the development of slip marbling used to decorate the elaborate classical vessels for which the partnership of Wedgwood and Thomas Bentley (1769–1780) is best known. Many British potters later used this technique on the more utilitarian creamwares and pearlwares. In an attempt to imitate the natural geological surfaces of the ancient wares Bentley was sending back from Italy, Wedgwood employed several methods to create the appearance of marble. In addition to using slips, he also used multicolored clays wedged together and either turned or press-molded (known today as solid agate). When placed on a simple lathe and shaved smooth, the solid agate body’s surface produced the desired pattern of contrasting shades and colors.

The use of slip for marbled decoration required pouring several colors onto the vessel’s surface as it revolved slowly on the lathe. Marbled slip, in contrast to agate decoration, appears more fluid, with longer, smoother divisions between shades and colors. Although known for his ornamental wares, Wedgwood may have used these techniques in the manufacture of utilitarian wares in his partnership with his cousin Thomas during the same period. The marbled slip could also be combed or feathered, giving the surface an appearance reminiscent of marbled end papers (fig. 6).

Archaeological evidence from the site of the Staffordshire potter William Greatbatch has been extensively documented and provides some insight into the production of marbled slip on creamwares and pearlwares.[5]Sherds deposited between 1775 and 1782 include marbled-slip tea wares, combed and uncombed. In some instances, the marbled-slip patterns are used in conjunction with blue-painted chinoiserie decoration (fig. 7). The earliest evidence that these variegated wares were imported into America comes from a Rhode Island newspaper advertisement offering the contents of the brig Three Sisters in 1781.[6]The cargo included “blue and white, marbled and Cream-colour’d Crockery.” A similar advertisement in the Boston Gazette and Country Journal, December 22, 1783, carried an advertisement for “CROCKERY WARE, Consisting of blue and white China glazed, red and white enamel’d, best printed, variegated &c cream colour’d ware.”[7]

Another type of dipped ware was being used in America earlier, however. An archaeological investigation of (British) Fort Watson in South Carolina produced a hemispherically-shaped pearlware bowl with a black inlaid checkered rim above a powder blue speckled slip field (not unlike the surface Wedgwood called “porphyry”). Fort Watson was erected in December 1780 and captured and destroyed by American forces in April 1781.[8]

Similar wares were found in an underwater deposit left by the American ship Washington off the coast of Les Isles du Glénan. The ship is purported to have ripped a hole in its hull at that location in 1787. Sherds recovered from the site included examples of tea wares and mugs with solid and speckled slip fields below inlaid checkered rims, intertwined reeded handles with elaborate foliate terminals, sprigged foliate devices on slip fields, and slip fields interrupted by horizontal grooved bands cut through the slip. The impressed backstamp “heath” occurred in the assemblage as well.[9]

Tea wares that survive with rouletted, checkered inlaid bands and solid or speckled slip fields sometimes have added types of slip decoration. The type most often found features a field of inlaid agate, so-called because the shallow inlay is made up of multicolored bits of clay adhered to the pot’s surface with a thin coating of slip and turned smooth (fig. 8). A saucer of this type, which descended in the Hollister family of Glastonbury, Connecticut, was illustrated in the catalog accompanying the exhibition The Great River: Art & Society of the Connecticut Valley 1635–1820 at the Wadsworth Atheneum, Hartford.[10]

While exuberant types of slip decoration usually receive the greatest attention, simple slip bands in one or many colors were used on a wide range of utilitarian vessels throughout the nearly 170-year period of dipped ware production. Heather Lawrence wrote about various pottery sites in Yorkshire where the sherd descriptions include entries such as, “one jug has horizontal slip banding.”[11] Similarly, Alwyn and Angela Cox, in their research on the Rockingham factory at Swillington, Yorkshire, refer to comparable sherds (fig. 9).[12]

Donald Towner, in his book The Leeds Pottery, calls another category of slip-decorated earthenware “encrusted ware.”[13] The slip field in this case was replaced by a pebbly surface of bits of multicolored clay attached by slip. Predecessors of this type of decorative technique include the rough-coated Staffordshire and Nottinghamshire bear jugs and salt-glazed wares. This decoration has also been called “cole slaw” decoration, with ground bits of clay allowed to remain textured on the pot’s surface (fig. 10).

Historical archaeologists on both sides of the Atlantic are beginning to understand how important it is to recognize the evolution of the different styles of slip decoration along with the more traditional attributions of body type and vessel form. The most common form of dipped wares found archaeologically is the bowl. The earliest shape of bowl is hemispherical, in imitation of the Chinese porcelain shape. British bowls of the last three decades of the eighteenth century are hemispherical with a comparatively tall foot ring, slightly tapered in profile. Most bowls of this shape were decorated with marbling, checkering, or engine turning.

In the first decade of the nineteenth century, the shape of these bowls changed quite abruptly. In 1807, the porcelain industry introduced the so-called London shape. It appears that earthenware manufacturers lost no time in copying this form. Although slip marbling is one of the most commonly found slip decorations on hemispherical bowls, it is rarely found on the London shape (fig. 11, 12).

It is important to know that slip colors and body composition relate to the evolution of dipped ware types. Composition of clay bodies varied not only among different potters, but also within each pottery from time to time. A potter may have experimented with different combinations of clay, flux, flint, and other materials to arrive at a “best body,” but that best body could well have been superseded at any time.

The interaction between the leaded glazes and various earth colorants plays a part in the final appearance of many slip-decorated wares. A large percentage of surviving examples of dipped ware from the period 1770 to 1840 bear rouletted bands colored with copper oxide glaze, which produced a rich, translucent green. The green is dependent on the lead for its richness. Less frequently, rouletted bands are colored with cobalt and, rarely, with either antimony or uranium, which produce a brilliant yellow. The ingredients used to produce this yellow glazing proved to be highly toxic and their use was confined to a short period in the early nineteenth century, according to the late ceramic historian C. John Smith.[14]

As with most aspects of ceramic history, there are no absolutes. For example, some of the hemispherical bowl fragments found in the third deposition of the Greatbatch site (1775–1782) have rounded foot rings rather than tapered ones. The hemispherical shape can also be found on later nineteenth-century bowls after the London shape had fallen out of fashion. But the London-shape bowl is most often found with slip decoration that did not appear until the 1790s in one case, and after 1810 in other cases.

The 1790s saw the introduction of the true mocha decoration, or so existing documents would indicate. London merchants of the late eighteenth century imported a type of semiprecious stone from Arabia to set in jewelry. This stone, a moss agate, when fractured revealed a treelike or mossy pattern. The stones were shipped through the port of Mocha (“el Mukha”) in Yemen, hence the name “mocha stone.” The first reference to pottery with this type of marking comes from the potters Lakin and Poole via the nineteenth-century ceramic historian Llewellyn Jewitt. In his massive undertaking The Ceramic Art of Great Britain (1878), Jewitt listed the types of wares mentioned on various Lakin and Poole invoices dating from 1792 to 1796 and includes “mocoe tumblers.”[15]

The mocha stone patterning was adopted as a component of slip decoration techniques. Lathe-mounted greenware (unfired pottery at the leather-hard stage) was first coated with bands of slip (figs. 13, 14). The turner dipped a “camel hair pencil” (an artist’s brush) into an acidic solution the potters called “mocha tea” and applied it by touching the tip of the brush to still-wet slip bands (fig. 15-17). The chemical and physical reaction between the “tea” and the wet slip caused the dendritic design to form nearly instantaneously (fig. 18). An observer of the process in 1833 described it as follows:

The “Moco” pattern on the outside of basons makes them appear as if delicate branches of seaweed had been laid upon their surfaces. This mock seaweed is not unlike thefucus sauginens, only it is not so red. The fluid employed is a preparation of tobacco-water; and in applying it the effect is brought out with but little waste of either time or labour. A camel’s hair pencil full of this decoction is taken in the hand, and with the point of it the surface of the bason is dotted with two or three dots where the pattern is intended to be. The fluid instantly spreads and runs into these ramifications.[16]

It appears that most potters developed their own recipes for the mocha solution. Surviving period recipe books call for the inclusion, among other things, of printer’s ink, hops, tansy, and urine (fig. 19). Thomas Brameld of the Rockingham factory at Swinton, Yorkshire, recorded his recipe as “1 iron scales, calcined; 1 Painter’s Blue, calcined; and 1 Manganese [meaning equal parts thereof]. Memo: Being short of a good vinegar, James Barrow one day tried a small quantity of spirits of turpentine along with his old colour and it answered very well. May 1808. T .B.”[17]

The various coloring agents had to be suspended in some form of acidic fluid that, on introduction to the alkaline of the slip, ramified into the treelike patterns through a form of capillary action. With the earliest mention of this “mocha,” “moco,” or “mocoe” in the last decade of the eighteenth century, it is interesting to note that dendritic decoration remained in production until 1939—nearly 150 years.

Another important category of slip decoration widely employed throughout the British potteries involved the use of the three-chambered slip cup (fig. 20). A unique tool was developed to permit multiple colored slips to be used in combination to create several related patterns (fig. 21). An early clue to the use of this tool can be found in the description of a patent granted to Richard Waters of Lambeth on October 23, 1811. The pertinent section reads as follows: “I do so mark or cloud the ware called Welsh ware by using a number of pipes or tubes at once instead of one pipe or tube through which the colouring slip or material is made to flow by which means the operation is better and more speedily performed.”[18]

The documents relating to this patent have no drawings of the device. Waters’s description suggests an object, believed to have been a slip pot, constructed with three separate compartments (fig. 22), each of which had a small hole into which a tube (in practice, a goose quill) was inserted. The tubes were arranged to form a conjoined spout (fig. 23) through which three separate and discrete colors could form a single fluid drop or stream (fig. 24, 25).

An 1833 observer describes the function of this tool, which was greatly employed throughout the potteries:

On some [ornamenting common basins] was soon done by dropping mixtures of three or four different colours on the bason, from so many different spouts attached to one vessel containing the mixtures; but this vessel, of course, had several compartments within it.[19]

A single drop from the three-chambered slip cup produced a design that collectors have termed “cat’s-eye” (fig. 26). A series of cat’s-eyes, overlapped, produced a pattern that the potters referred to as “cable” or “common cable” (fig. 27, 28). This device also produced a pattern called “twig” by collectors (fig. 29). This pattern was created by quickly trailing a series of opposing, connected curves onto the wet slip surface of a vessel (fig. 30). These twig patterns probably postdate 1807, as they do not appear on the earlier hemispherical bowls. They do, however, appear to continue to be used throughout the nineteenth century. Sherds from the Podmore, Walker & Co. Swan Bank site in Tunstall, Staffordshire, have both cat’s-eye and cable decorations on fairly standard gray, blue, and black bands of this somewhat later period, 1853 to 1859 (fig. 31). By this time, slip decoration colors were more conservative and the practice of adding glaze colors to rouletted bands had disappeared.

Wares ornamented with cat’s-eyes and cable decoration are well represented in tavern and household archaeological assemblages of the first half of the nineteenth century along America’s eastern seaboard. Archaeological evidence suggests that the bowl was the most common form of dipped ware used in American households. A ground scatter at the late-eighteenth-century Nathan Southworth house in Deep River (originally Saybrook), Connecticut, produced evidence of eleven different dipped ware bowls among sherds encompassing many of the expected wares of the first half of the nineteenth century. These other wares included a dinner service in the Park Scenery pattern printed in black by G. Phillips & Co. of Longport, Staffordshire, red-and-green Canova pattern by T. Mayer of Stoke, an assortment of blue-and-green shell-edged wares, slip-trailed American redware, and portions of two black-glazed redware teapots of the type made by Thomas Crafts at Whately, Massachusetts.

Other types of slip decoration belong in this overview. We refer to one as “dipped fan,” partly because of the process and partly because of the resulting effect (fig. 32-34). Collectors have given this design a variety of names, including “tobacco leaf,” “balloon,” “lollipop,” and “palmate.” Extant examples of this pattern are inexplicably scarce, but archaeological evidence shows that factories from Bovey Tracey in Devon to Musselborough in Scotland produced it. It may have also been produced at the Downshire creamware factory in Belfast, Northern Ireland.[20] Sherds of the fan pattern were found by the authors at the Clay Mill Pottery site in Baglan, near Port Talbot in Wales. The decoration on those fragments occurs on an earthenware body, the color of which varied from a pale buff to a dark red. Only one extant example of the fan pattern is known to bear a maker’s mark, that of John Shorthose.[21]

Another decorative pattern is actually a continuation of the seventeenth-century method of slip trailing. In most cases, this was done with a single-chambered slip cup fitted with three or four parallel tubes. One method even involved the use of a four-chambered “worming” pot to apply parallel slip lines, each of a different color (fig. 35). Some recent archaeological evidence suggests these four-colored, slip-trailed examples are from the Annfield Pottery of John Thomson in Glasgow.

By the middle of the nineteenth century, the American market for British industrial slipwares was on the wane. The wares of the mid-nineteenth century and later lacked the brighter, earthier colors of the earlier wares. American pottery manufacturers were producing much plainer utilitarian wares for the home market in increasing numbers. Slip-banding traditions continued well into the late nineteenth century with the American yellowware manufactures in Ohio and Kentucky.

Production continued in England, however, with mocha mugs and jugs becoming certified units of measure for use in pubs and markets (fig. 36). Many of these later objects bear some form of capacity verification mark, usually sand-blasted through the glaze. These marks include a reference to the throne, the date and the excise district number (fig. 37). An example would be e02r 379. The “er” is for Edward Regis, the “02” for 1902, and the “379” for the excise district of Burton-on-Trent. It is likely that local potteries served local excise districts, so it is probable that a mug bearing that marking would have been made at T. G. Green & Co. in Church Gresley.

The contribution of the British slipware manufacturers cannot be overstated. A tremendous variety of these cheap, colorful utilitarian wares was available to the American consumer from the 1780s well into the 1850s. In viewing the relatively few examples that have survived intact, the visual impact that these wares had on the domestic landscape must have been considerable. Today, when archaeologists uncover large quantities of dipped sherds, the visual impact is still significant to the contemporary eye.

In 1998, a large cache of wasters attributed to the Enoch Wood factory (1831–1845) was discovered in Burslem. Sherds that parallel the jug illustrated in figure 38 were found in the assemblage. This particular jug has a long history of ownership in a house in Great Barrington, Massachusetts. It exhibits signs of heavy use, a common characteristic of surviving dipped wares, since these wares were intended for use. The fact that any survive is perhaps the best testament to the visual appeal of these bright and fancy wares and the ingenuity of the British slipware potters.

Leslie Grigsby, English Slip-Decorated Earthenware at Williamsburg (Williamsburg, Va.: The Colonial Williamsburg Foundation, 1993).

Cited in Katherine Eufemia Farrer, Wedgwood’s Letters to Bentley, 1762–1770 (London: For private circulation, 1903), pp. 17, 18.

Ibid., p. 47.

Ibid., p. 177.

David Barker, William Greatbatch: A Staffordshire Potter (London: Jonathan Horne, 1989).

John L. Seidel, “China Glaze Wares on Sites From the American Revolution,” Historical Archaeology 24, no. 1 (1990): 91.

Ibid.

Leland G. Ferguson, “Analysis of Ceramic Materials from Fort Watson, December 1780– April 1781,” in Conference on Historic Site Archaeology Papers edited by Stanley South (Columbia: University of South Carolina, 1973) vol. 8, pp. 2–28.

Bernard de Maisonneuve, in a report on marine excavation, “Sites des Faiences. XVIIIème

Siècle/Iles de Glenan,” Saint Gilles Croix de Vie, France (Association de Recherche Historique Maritime et Sous-Marine), January 2, 1990.

Elizabeth Pratt Fox, “Ceramics and Glass,” in The Great River: Art & Society of the Connecticut Valley, 1635–1820, edited by Gerald W. Ward and William N. Hosley (Hartford, Conn.: Wadsworth Atheneum, 1985), p. 426, cat. no. 285.

Heather Lawrence, Yorkshire Pots and Potteries (Newton Abbot and North Pomfret, Vt.: David & Charles, 1974), p. 21.

Alwyn Cox and Angela Cox, Rockingham Pottery and Porcelain 1745–1842 (London: Faber & Faber, 1983), pp. 48–52.

Donald Towner, The Leeds Pottery (London: Cory, Adams & Mackay, Ltd., 1963), p. 47.

C. John Smith, in a lecture at the Shelburne Museum, Shelburne, Vermont, October 1981.

Llewellyn Jewitt, The Ceramic Art of Great Britain (New York: Scribner, Welford, and Armstrong, 1878).

Peter Orlando Hutchinson, Journal (reprinted as Longton, 1833), Annual Report & Transactions of the North Staffordshire Field Club, vol. 49 (1914–15), p. 57.

Cited by Margaret E. Turnbull, “Mochaware,” The Antiques Journal (August 1974): 42–43.

Pat. No. 54/8887/ pen/1332.

Hutchinson, Journal, p. 57.

Peter Francis, “Irish Creamware: The Downshire Pottery In Belfast,” English Ceramic Circle Transactions 15, part 3 (1995): pp. 400–25; cover illustration.

A cylindrical teapot illustrated in Jonathan Rickard, “Mocha Ware,” Antiques (August 1993): 187.